Novel industrial crystallization technology for cefamandole nafate

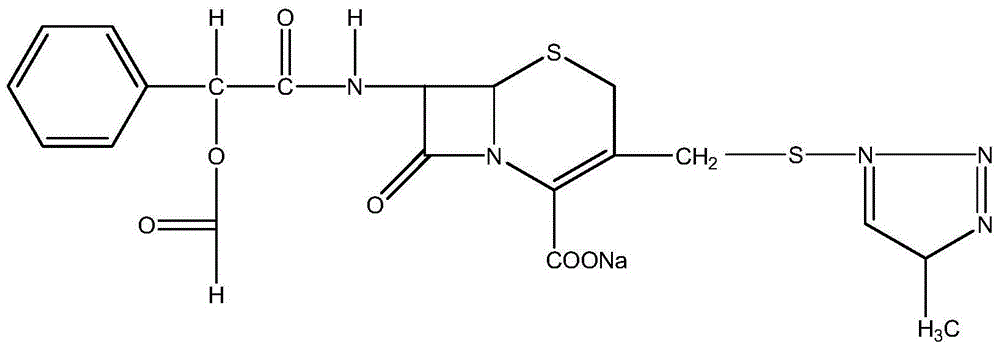

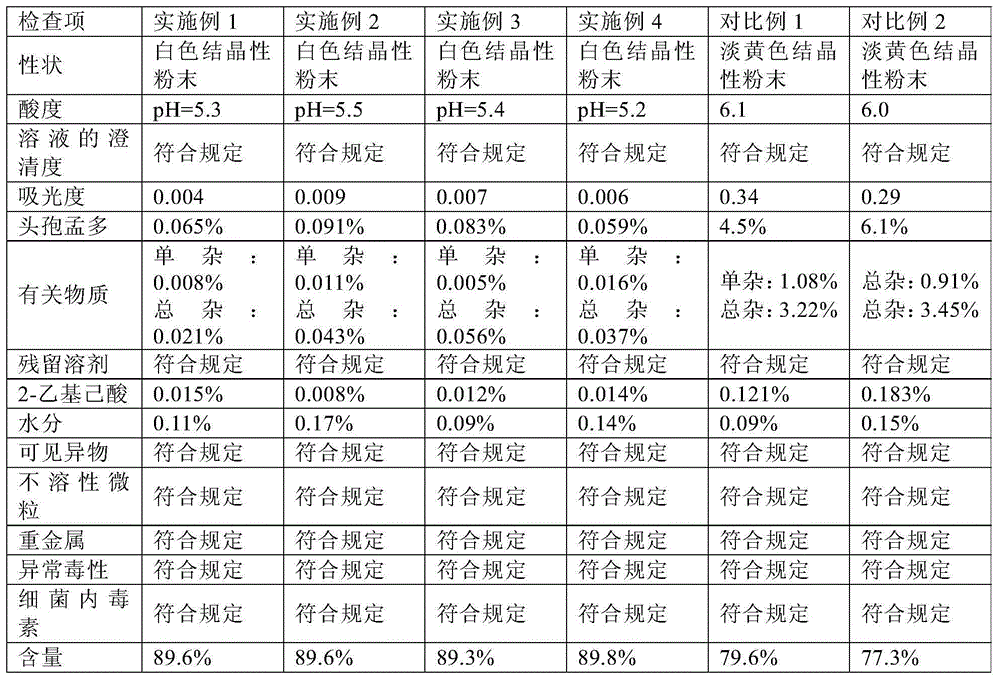

A technology of cefamandole sodium and industrial crystallization, which is applied in the field of medicine, can solve the problems of cefamandole sodium with many impurities, poor solubility, poor stability, etc., and achieve no solvent residual toxicity, short crystallization time, and high crystallization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

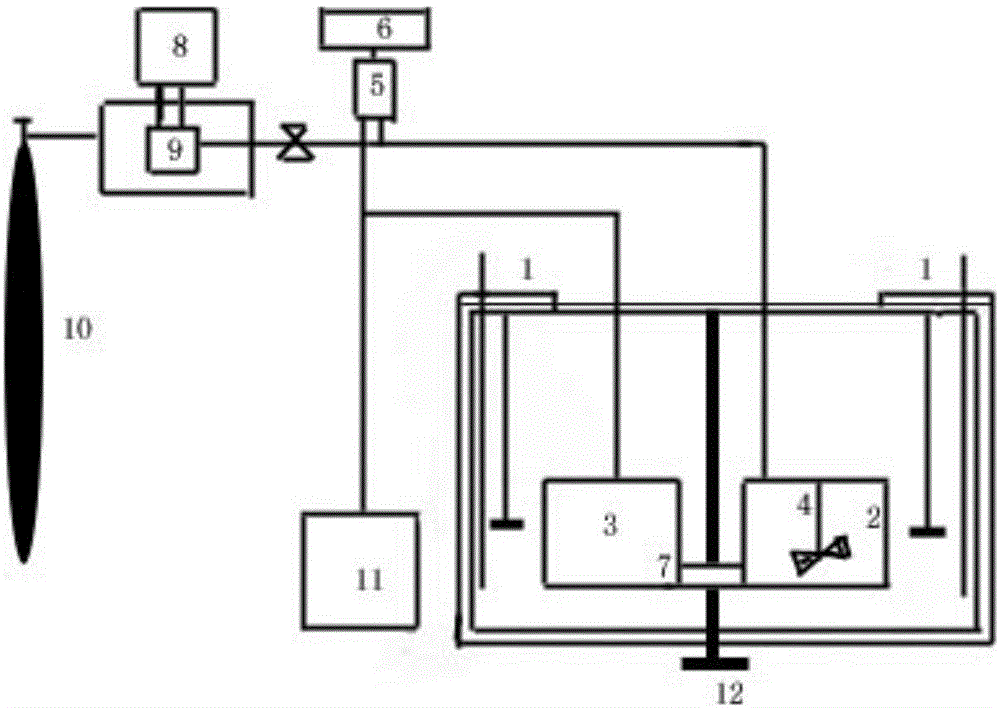

Method used

Image

Examples

Embodiment 1

[0045](1) taking by weighing 4.01kg of cefamandole sodium crude product with a purity of 83.51% is placed in the extraction tank, adding 40kg of mixed solvent of 65% acetone water, controlling the temperature at 45°C, and stirring to make it dissolve;

[0046] (2) Pump in CO with a high-pressure liquid pump 2 Fluid to 10Mpa, stir, and maintain the pressure and temperature for 5 minutes, turn off the high pressure pump;

[0047] (3) Place crystal seeds in the crystallization pool, raise the height of the extraction pool to 25cm, open the quick interface of the two pools, make the liquid in the extraction pool enter the crystallization pool, and close the quick interface;

[0048] (4) Regulate the pressure in the crystallization tank to be 0.5Mpa, the temperature is 20°C, and keep this temperature and pressure for 30 minutes;

[0049] (5) After cooling down the system, after depressurization, dry under reduced pressure to obtain 3.02 kg of high-purity cefamandole sodium crystal...

Embodiment 2

[0052] (1) taking by weighing 5.64kg of cefamandole sodium crude product with a purity of 83.51% is placed in the extraction tank, adding 60kg of mixed solvent of 90% acetone water, controlling temperature at 65°C, and stirring to dissolve it;

[0053] (2) Pump in CO with a high-pressure liquid pump 2 Fluid to 30Mpa, stir, and maintain the pressure and temperature for 15 minutes, turn off the high pressure pump;

[0054] (3) Place crystal seeds in the crystallization pool, raise the height of the extraction pool to 30cm, open the quick interface of the two pools, let the liquid in the extraction pool enter the crystallization pool, and close the quick interface;

[0055] (4) Regulate the pressure in the crystallization tank to be 5Mpa, the temperature is 30°C, and keep this temperature and pressure for 10 minutes;

[0056] (5) After the system cools down, after decompression, dry under reduced pressure to obtain 4.53 kg of high-purity cefamandole sodium crystalline product, a...

Embodiment 3

[0059] (1) taking by weighing purity is that 83.51% cefamandole sodium crude product 4.86kg is placed in the extraction tank, adds the mixed solvent 50kg of 80% acetone water, controls temperature 50 ℃, stirs and makes it dissolve;

[0060] (2) Pump in CO with a high-pressure liquid pump 2 Fluid to 20Mpa, stir, and maintain the pressure and temperature for 10 minutes, turn off the high pressure pump;

[0061] (3) Place crystal seeds in the crystallization pool, raise the height of the extraction pool to 30cm, open the quick interface of the two pools, let the liquid in the extraction pool enter the crystallization pool, and close the quick interface;

[0062] (4) Adjust the pressure in the crystallization tank to be 3Mpa, the temperature is 25°C, and keep this temperature and pressure for 20 minutes;

[0063] (5) After cooling down the system, after depressurization, dry under reduced pressure to obtain 3.77 kg of high-purity cefamandole sodium crystalline product, and obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| stone rate | aaaaa | aaaaa |

| stone rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com