Coating composition containing hyperbranched blocked polyisocyanate

A polyisocyanate and isocyanate technology, applied in the field of coatings, can solve problems such as unfavorable application, high viscosity, and inability to effectively form high crosslinking density paint films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

[0106]

[0107]

Embodiment 1

[0109] B1: Synthesis of H40-25% IPDI-CAP (25% of the hydroxyl groups of the hyperbranched resin H40 are replaced by IPDI-caprolactam)

[0110] Synthesis of IPDI-caprolactam semi-blocked prepolymer (IPDI-CAP)

[0111] At room temperature, mix 100.0 parts of IPDI, 50.9 parts of caprolactam, 226.3 parts of cyclohexanone and 0.37 parts of dibutyltin dilaurate (DBTDL) according to the mass ratio, heat and stir the mixture to 65°C under the protection of nitrogen, and keep it warm at 65°C for reaction 2 to 3 hours until NCO % reaches 5.0% wt.

[0112] Synthesis of H40-25% IPDI-CAP

[0113] Under the protection of nitrogen, 100 parts of BoltronH40 and 150 parts of cyclohexanone were mixed according to the mass ratio, and the mixture was heated and stirred to 110°C until all the H40 was dissolved. After cooling down to 80°C, 187 parts of IPDI-CAP semi-blocked prepolymer was added dropwise at a uniform speed, and the addition was completed in about 30 minutes. Insulate the reaction ...

Embodiment 2

[0116] B2: Synthesis of H40-50%-IPDI-CAP (50% of the hydroxyl groups of hyperbranched resin H40 are replaced by IPDI-caprolactam)

[0117] Same as the step of Example 2, the difference is that the amount of the IPDI-CAP semi-blocked prepolymer is doubled to 374 parts, and the light yellow solution of the gained is: 50% H40 hydroxyl group is covered by IPDI-caprolactam semi-blocked prepolymer (IPDI -CAP) substituted hyperbranched blocked polyisocyanate, the final product is adjusted to a solid content of 40% with cyclohexanone.

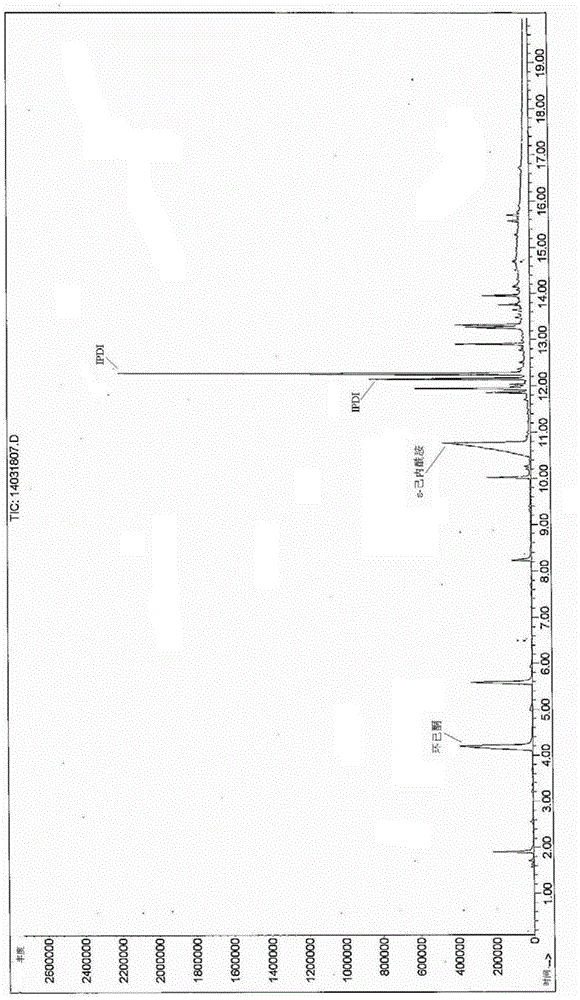

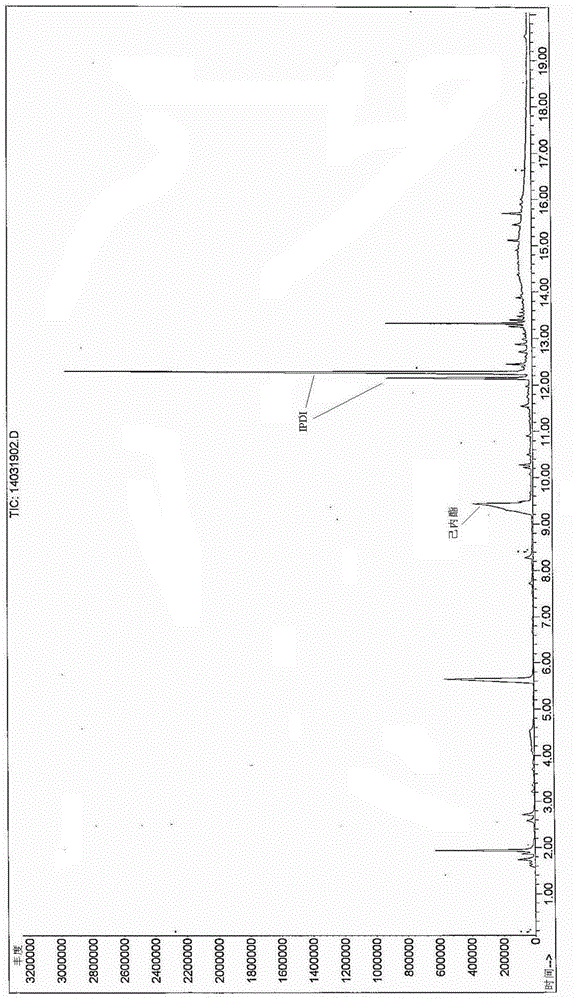

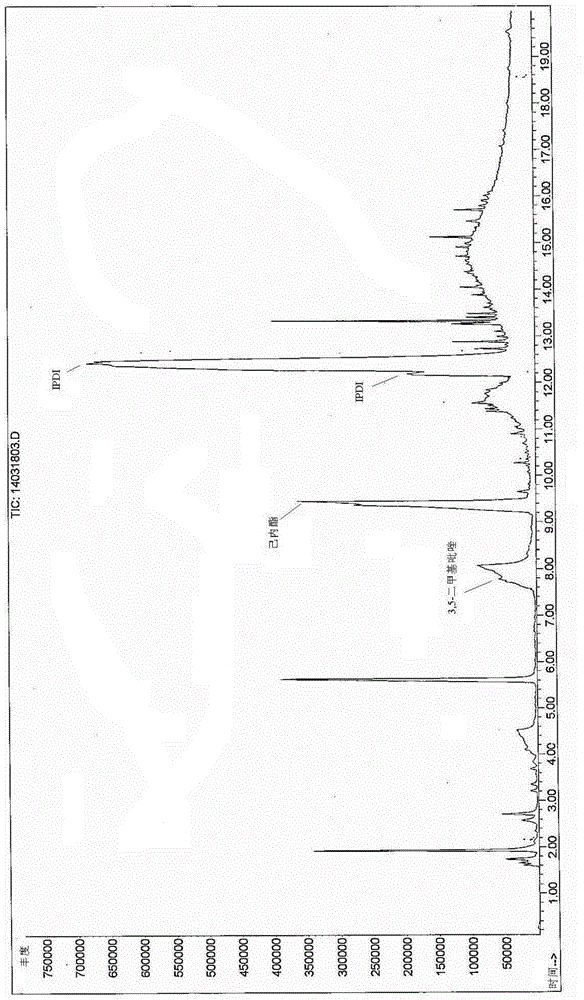

[0118] attached figure 1 Be the pyrolysis gas chromatography-mass spectrogram of present embodiment product, by figure 1 The functional group situation of the synthesized product of this embodiment can be known.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com