Boron cross-linking agent and boron crosslinking fracturing fluid used for high temperature deep well

A cross-linking agent and one-component technology, applied in the field of boron cross-linked fracturing fluid, can solve the problems of not being able to meet the construction requirements of fracturing fluid, poor temperature resistance, high construction friction, etc. Excellent effect of low resistance and high shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of boron crosslinking agent:

[0028] Add trimethyl borate and triethanolamine with a mass ratio of 2:1 to the reactor as a reaction, add sodium hydroxide to adjust the pH value to 8, react at 68°C for 3 hours, then add a mass ratio of 1:3 borax and isopropanol, and add 4 times the quality of triethanolamine water, stir well, react at 80°C for 2 hours, after the reaction, cool to get the product which is the boron crosslinking agent.

[0029] (2) Use the above-mentioned boron cross-linking agent to prepare boron cross-linking fracturing fluid suitable for high-temperature deep wells:

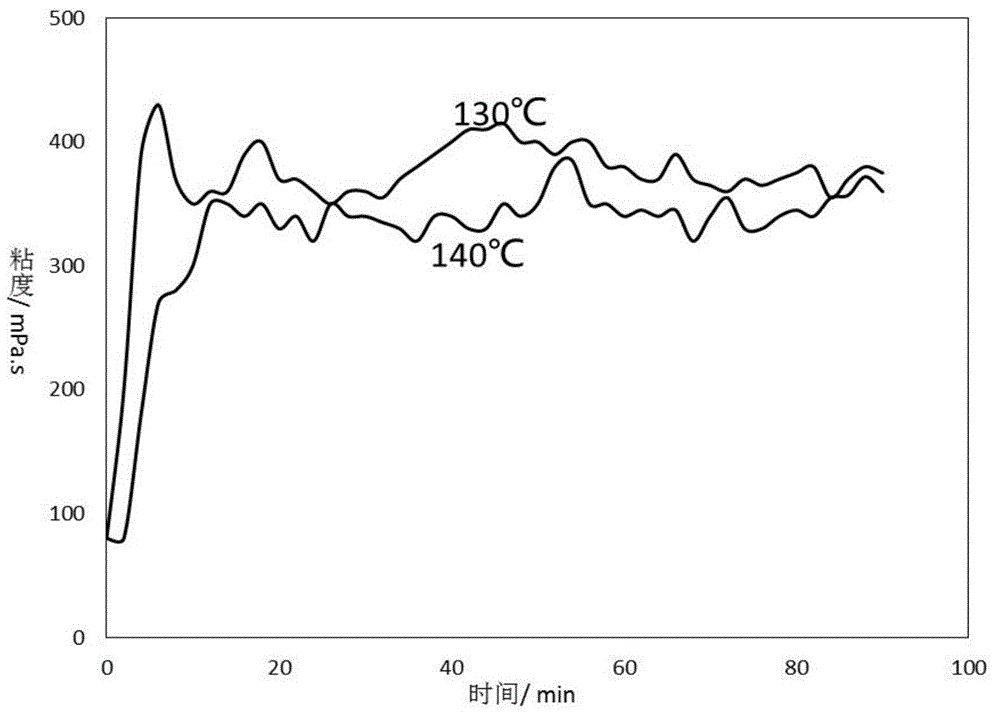

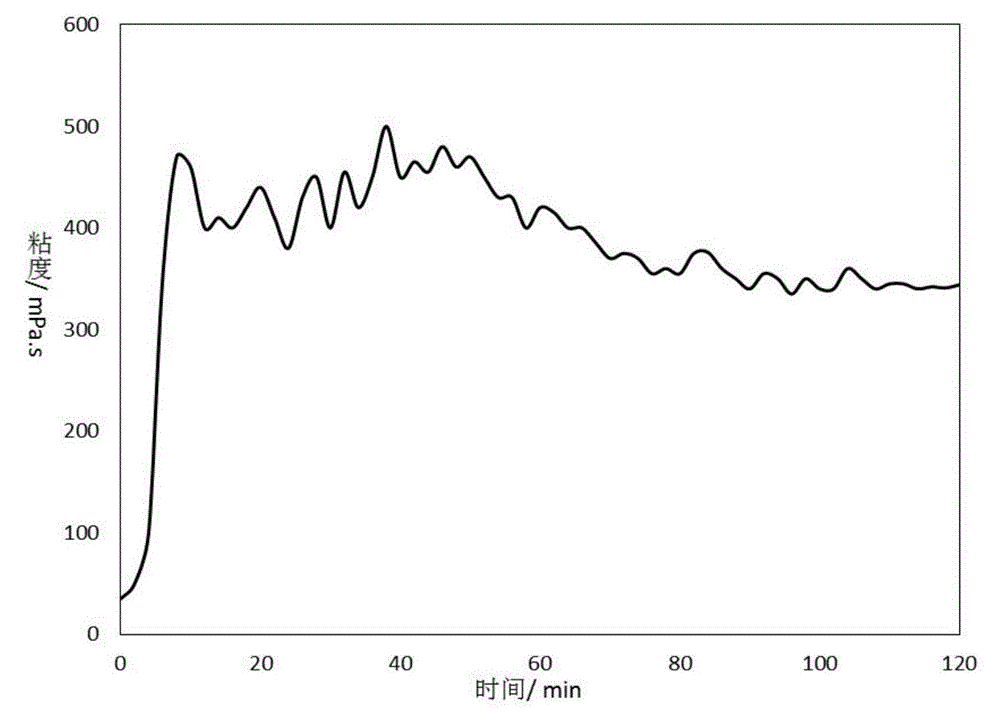

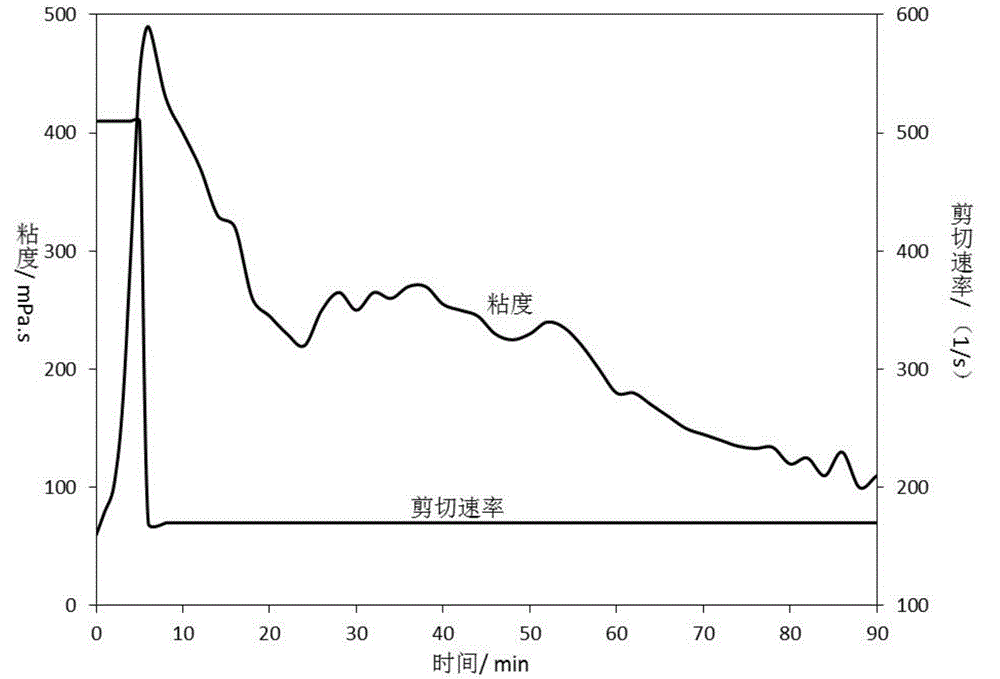

[0030] Taking the total mass as 100%, first add a certain amount of water, 2% potassium chloride, 0.02% sodium hydroxide, 0.02% dodecyldimethylbenzyl chloride, 0.03% sodium thiosulfate to the Warring mixer , 0.04% fluorocarbon surfactant, add 0.6% hydroxypropyl guaridine gum into it under the condition of constant stirring, after the liquid becomes viscous, add 0.035% bor...

example 1

[0048] In a certain exploration well in Jidong Oilfield, the formation temperature is 172°C, which is the highest formation temperature in the well, and its fracturing layer: ES 3 3 ; Well section: 4740.9~4761.0m; Thickness: 9.6m; Number of layers: 4. Because the oil well is very deep, the geological conditions of the formation are complicated, and the construction is difficult, the success rate of the past construction has been relatively low. Later, OCB-I type boron cross-linked fracturing fluid system was used for fracturing in this area. Among them, the fracturing method: oil casing mixed injection, combined layer fracturing; construction pipe string combination requirements: N80- 73mm thickened tubing; bell mouth position: 3200.0m; wellhead requirements: 1000# Christmas tree; the well is designed to add 61.6 tons of sand (0.45-0.90mm high-strength ceramsite) and 340m of boron cross-linked fracturing fluid 3 , gelling water 95m 3 , the construction friction of this wel...

example 2

[0050] A certain exploratory well in Zhongyuan Oilfield, the construction section of this well: 3619.7-3946m; construction method: oil casing mixed injection, one injection and two pressures; porosity: 15.0-23.0%; proppant ceramsite: 120m 3 ; Formation temperature: 160°C. The well is fractured with OCB-II boron cross-linked fracturing fluid system, and the well is designed to add 0.45 / 0.90 ceramsite for 80m 3 , fracturing fluid 745m 3 , active water 90m 3 After fracturing, the well increased oil production by an average of 8.5 tons per day, with a validity period of 60 days, and a total oil increase of 204,000 tons.

[0051] Field construction proves that the deep well high temperature resistant boron cross-linked fracturing fluid has good high temperature high shear resistance and flowback capacity, especially in exploration wells with poor geological conditions can still achieve good construction results, which fully demonstrates that the boron crosslinked fracturing fluid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com