A multiphase composite magnetic nanowire array and its preparation method

A nanowire array and composite magnetic technology, which is applied in the field of preparation of magnetic nanowire arrays, can solve the problems of pollution and poor structural stability in the preparation process, and achieve excellent magnetic anisotropy, high aspect ratio, and improved deposition rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of AAO template and electrode pretreatment

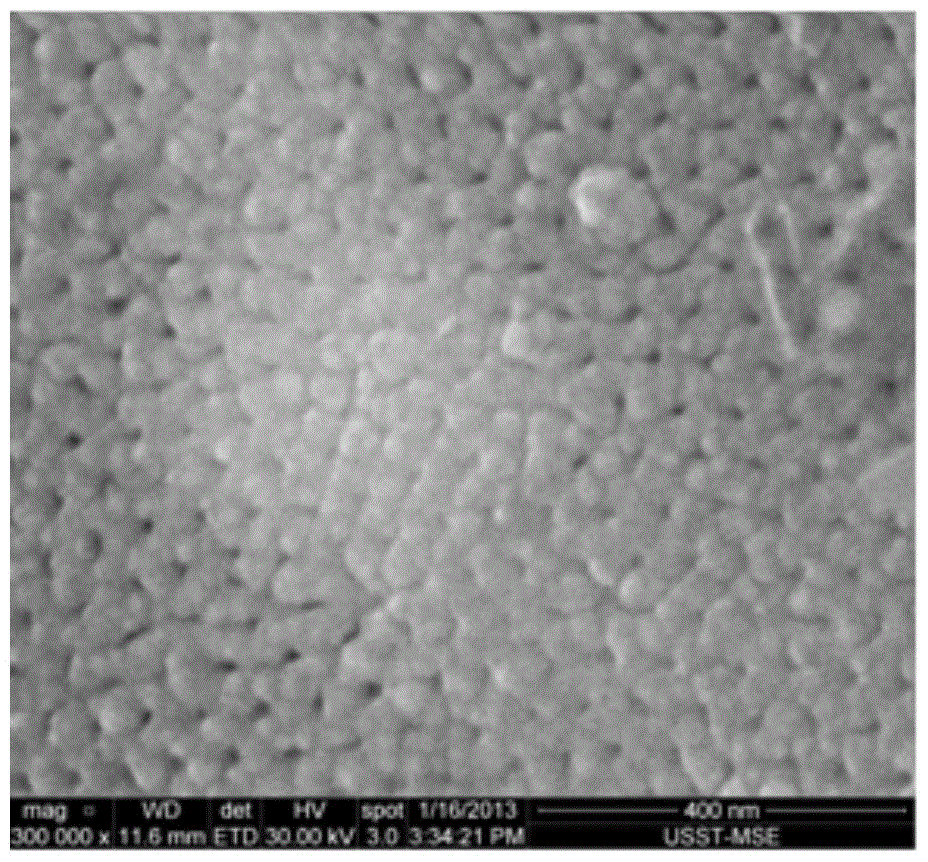

[0028] Cut the annealed aluminum foil into a disc with a diameter of 2 cm and flatten it, then place it in acetone and absolute ethanol in sequence, and use an ultrasonic cleaner to vibrate and clean it for 5 minutes respectively, and use deionized water to wash the degreased aluminum foil repeatedly. Rinse well, and then soak in 10%wt NaOH solution for 15 minutes to remove the oxide layer on the surface of the aluminum foil. Then put it under the tap and rinse it with clean water for 20 minutes, and finally rinse it with deionized water. The electrochemical method is used for polishing, and the electrolyte is prepared by using absolute ethanol and perchloric acid in a volume ratio of 4:1. Finally, a template with uniform pore size is obtained through two oxidation processes. The gold-sprayed AAO template on the back is bonded to the Cu sheet with conductive adhesive to form a composite electrode, which is conne...

Embodiment 2

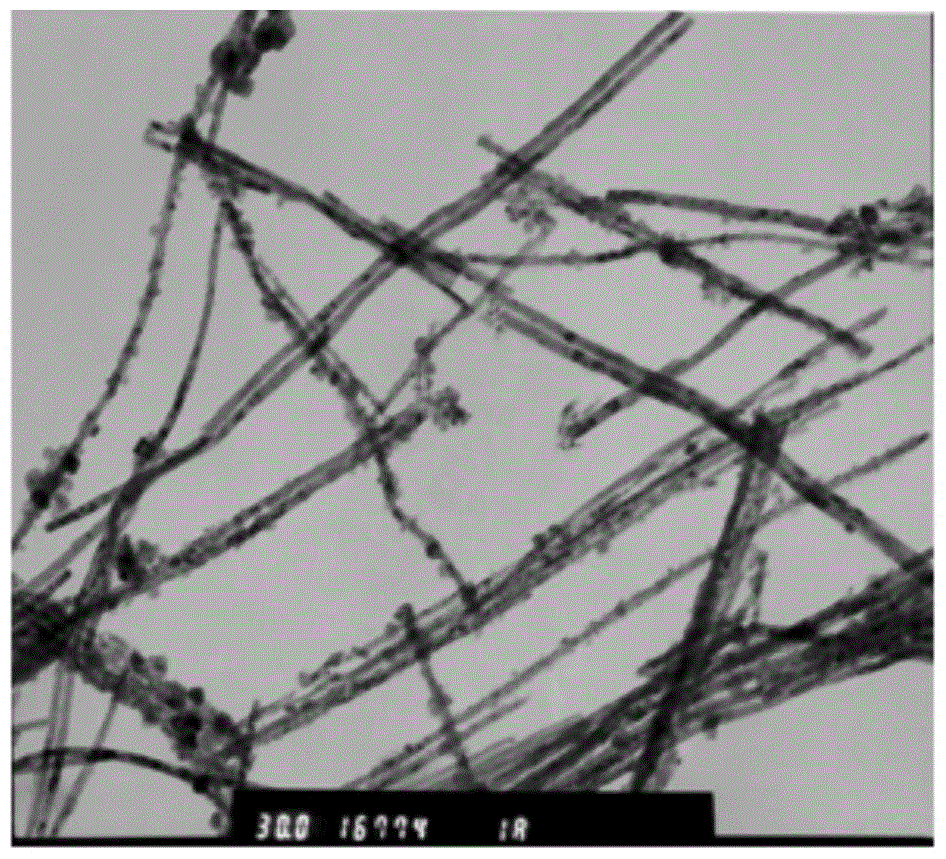

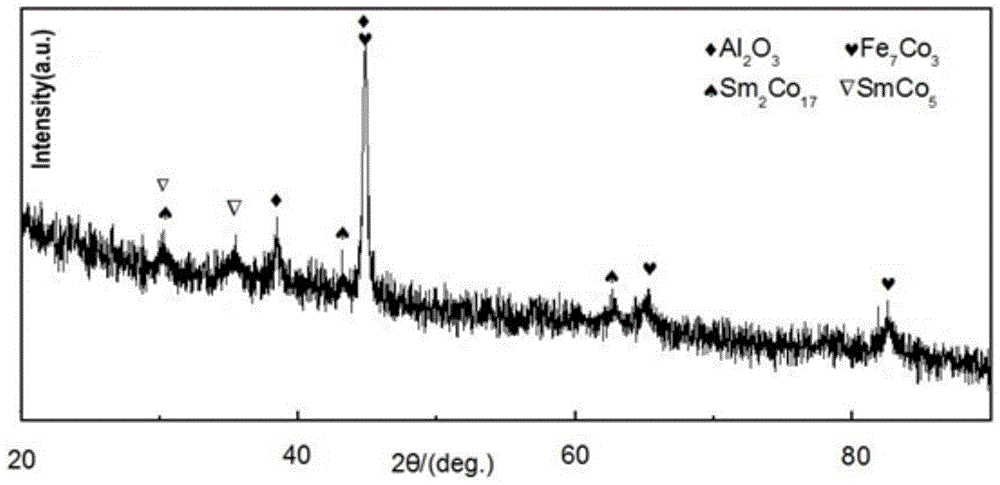

[0032] First prepare the Fe-Co electroplating solution and the Sm-Co electroplating solution respectively, wherein the composition of the Fe-Co electroplating solution is 0.2mol / L CoSO 4 ·7H 2 O, 0.15mol / L FeSO 4 ·7H 2 O, 0.7mol / L Na 2 SO 4 , 0.05mol / L of ascorbic acid and 0.4mol / L of H 3 BO 3 . The composition of Sm-Co electroplating solution is 0.2mol / L SmCl 3 With 0.05mol / L CoCl 2 And the additive components are 0.1mol / L boric acid, 0.12mol / L ascorbic acid and 0.16mol / L glycine. Place the pre-treated electrode connection circuit in the plating tank and place it on a magnetic stirrer to start the alternating deposition. First deposit the Fe-Co alloy for 80s, then quickly pour out the Fe-Co plating solution, rinse the electrolytic tank with deionized water, pour the Sm-Co plating solution into the deposition for 30s, and then replace the Sm-Co plating solution with Fe- The Co plating solution was deposited for 60 s and then cycled 30 times. When depositing Fe-Co, t...

Embodiment 3

[0034] Prepare the Fe-Co and Sm-Co electroplating solutions respectively, in which the composition of the Fe-Co plating solution is 0.2mol / L CoSO 4 ·7H 2 O, 0.15mol / L FeSO 4 ·7H 2 O, 0.7mol / L Na 2 SO 4 , 0.05mol / L of ascorbic acid and 0.4mol / L of H 3 BO 3 . The composition of Sm-Co electroplating solution is 0.2mol / L SmCl 3 With 0.05mol / L CoCl 2 And the additive components are 0.1mol / L boric acid, 0.12mol / L ascorbic acid and 0.16mol / L glycine. Place the pre-treated electrode connection circuit in the plating tank and place it on a magnetic stirrer to start the alternating deposition. First deposit the Fe-Co alloy for 80s, then quickly pour out the Fe-Co plating solution, rinse the electrolytic tank with deionized water, pour the Sm-Co plating solution into the deposition for 30s, and then replace the Sm-Co plating solution with Fe- The Co plating solution was deposited for 60 s and then cycled 30 times. When depositing Fe-Co, the temperature of the electroplating so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com