Milk protein concentrate with high heat stability and preparation method thereof

A milk protein concentrate, high thermal stability technology, applied in the direction of protein composition of milk, animal protein processing, protein food composition, etc. Powder properties, preventing protein denaturation, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Take fresh raw milk with a protein content of 3.2% (w / w), a fat content of 3.8% (w / w), a lactose content of 4.5% (w / w), an ash content of 0.7%, and heat it to 53 Centrifugal degreasing at ℃, centrifugal speed is 9000r / min, feed rate is 98L / h, adds sodium citrate and sodium pyrophosphate in above-mentioned skim milk, the proportioning of the two is 1: 1, and total addition is 0.3% ( w / w), stirred at 53°C for 8min, with a stirring rate of 80rpm, adjusted the pH value to 5.8 with 1mol / L HCl standard solution while stirring, and sterilized at 130°C for 5s;

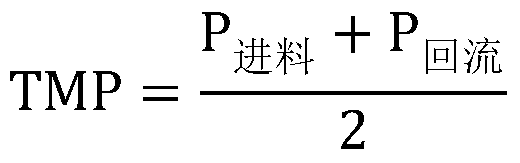

[0037] 2) Use a 10kDa regenerated cellulose membrane to carry out ultrafiltration of the sterilized skim milk in step 1), the ultrafiltration temperature is 15°C, and the pressure is 2×10 5 Pa, the membrane flux in the ultrafiltration process is 25L m -2 h -1 , after adding deionized water, the membrane flux is 30L m -2 h -1 ,specifically:

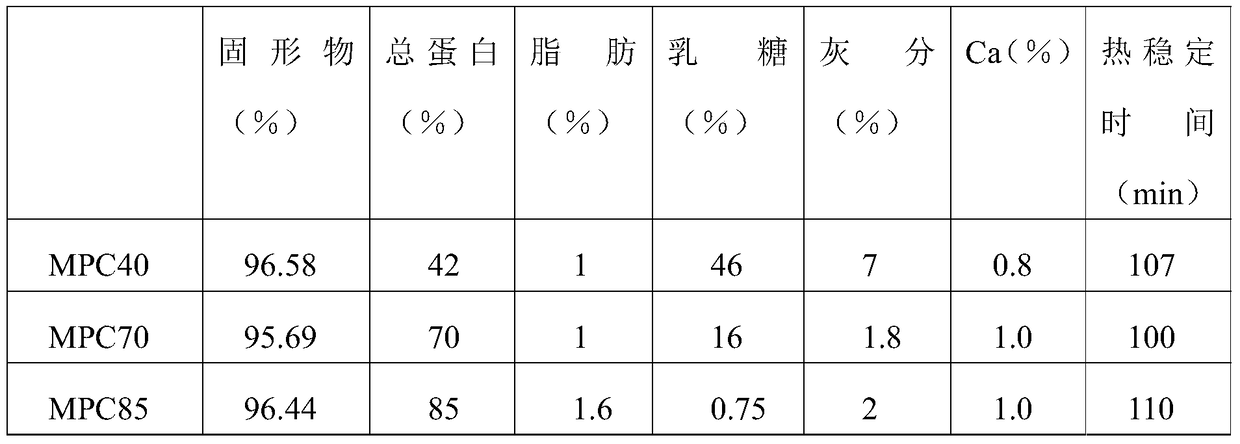

[0038] A. MPC40: Collect the retentate after ultrafiltration and concen...

Embodiment 2

[0043] 1) Take fresh raw milk with a protein content of 3.0% (w / w), a fat content of 3.85% (w / w), a lactose content of 4.0% (w / w), and an ash content of 0.6%, and heat it to 50 Centrifugal degreasing at ℃, centrifugal speed is 8000r / min, feed rate is 95L / h, adds sodium citrate and trisodium phosphate in above-mentioned skim milk, the proportioning of the two is 3: 7, and total addition is 0.1% ( w / w), stirred at 53°C for 5min, with a stirring rate of 50rpm, adjusted the pH value to 5.5 with 1mol / L HCl standard solution while stirring, and sterilized at 140°C for 3s;

[0044] 2) Use a 10kDa regenerated cellulose membrane to carry out ultrafiltration of the sterilized skim milk in step 1), the ultrafiltration temperature is 10°C, and the pressure is 1.5×10 5 Pa, the membrane flux in the ultrafiltration process is 20L m -2 h -1 , after adding deionized water, the membrane flux is 25L·m -2 h -1 ,specifically:

[0045] A. MPC40: Collect the retentate after ultrafiltration and ...

Embodiment 3

[0050] 1) Take fresh raw milk with protein content of 3.5% (w / w), fat content of 4.2% (w / w), lactose content of 4.95% (w / w), ash content of 0.80%, and heat to 55 Centrifugal degreasing at ℃, centrifugal speed is 10000r / min, feed rate is 100L / h, adds sodium pyrophosphate and trisodium phosphate in above-mentioned skim milk, the proportioning of the two is 4: 1, and total addition is 0.5% ( w / w), stirred at 55°C for 10min, with a stirring rate of 100rpm, adjusted the pH value to 6.0 with 1mol / L HCl standard solution while stirring, and sterilized at 135°C for 4s;

[0051] 2) Use a 10kDa regenerated cellulose membrane to carry out ultrafiltration of the sterilized skim milk in step 1), the ultrafiltration temperature is 40°C, and the pressure is 3×10 5 Pa, the membrane flux in the ultrafiltration process is 30L m -2 h -1 , after adding deionized water, the membrane flux is 35L·m -2 h -1 ,specifically:

[0052] A. MPC40: Collect the retentate after ultrafiltration and concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com