Method and device for garbage processing water recovery and pure carbon production

A technology for waste treatment and water recovery, which is used in waste treatment, solid waste removal, energy input, etc. It can solve the problems of innocence, resource utilization and reduction, and reduce pollutants and greenhouse gas emissions. , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

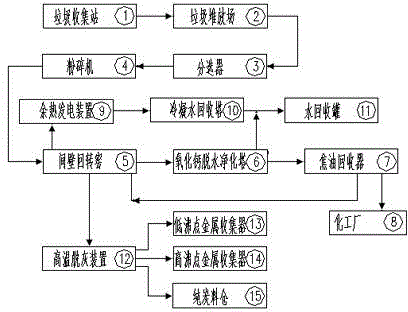

[0014] The device of the present invention for waste treatment and recovery of water and production of pure carbon is as figure 1 As shown, it includes garbage collection station 1, garbage dump 2, sorter 3, pulverizer 4, calcium oxide dehydration purification tower 6, partition wall rotary kiln 5, tar recovery device 7, chemical plant 8, waste heat power generation device 9, condensation Water recovery device 10 , water recovery tank 11 , high temperature deashing equipment 12 , low boiling point metal recovery device 13 , high boiling point metal recovery device 14 and pure carbon silo 15 . The garbage dump is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com