A double-network poly(n-acryloyl-l-α-amino acid)/hyaluronic acid composite hydrogel and its preparation method

A composite hydrogel and acryloyl technology, applied in the field of biomedical materials, can solve the problems of few applications, hydrogel brittleness and large modulus, and achieve the effect of simple process, good mechanical properties, and rapid reduction of dissociation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

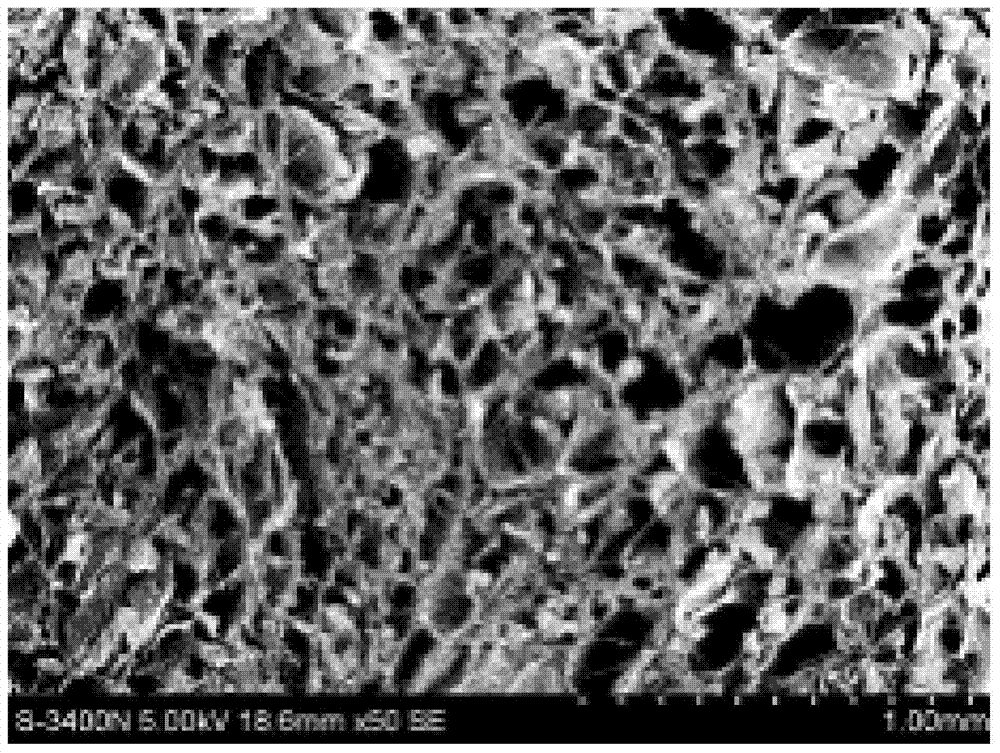

Image

Examples

Embodiment 1

[0028] 1) Preparation of hydrazide hyaluronic acid

[0029] Using the carbodiimide method, 2,2'-dithiodiacetylhydrazine was grafted onto hyaluronic acid with a molecular weight of 1 million to obtain hydrazide hyaluronic acid with a degree of substitution of 40%. The details are as follows: Combine hyaluronic acid, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride with N-hydroxysuccinimide, 2,2'-dithiodiacetyl Hydrazine was dissolved in distilled water to prepare a 1% hyaluronic acid solution. The pH of the system was adjusted to 5 with 1 mol / L hydrochloric acid, and the reaction was stirred at room temperature for 48 hours. After the reaction, the reaction system was dialyzed against deionized water for 2 days ( The molecular weight cut-off of the dialysis bag is 3500 Da, the same below) freeze-drying at minus 20°C for 72 hours to obtain hydrazide hyaluronic acid. Among them, the number of hyaluronic acid repeating units, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide ...

Embodiment 2

[0040] 1) Preparation of hydrazide hyaluronic acid

[0041] Using the carbodiimide method, 2,2'-dithiodiacetylhydrazine was grafted onto hyaluronic acid with a molecular weight of 2 million to obtain hydrazide hyaluronic acid with a substitution degree of 30%. The details are as follows: Combine hyaluronic acid, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride with N-hydroxysuccinimide, 2,2'-dithiodiacetyl Hydrazine was dissolved in distilled water to prepare a 0.5% hyaluronic acid solution. The pH value of the system was adjusted to 5.5 with 1mol / L hydrochloric acid, and the reaction was stirred at room temperature for 24 hours. The distilled water was dialyzed for 2 days with a dialysis bag with a molecular weight cut-off of 3500Da. Freeze-drying was performed at minus 20°C for 72 hours to obtain hydrazide hyaluronic acid. Among them, the number of hyaluronic acid repeating units, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, N-hydroxysuccinimide, 2,2...

Embodiment 3

[0051] 1) Preparation of hydrazide hyaluronic acid

[0052] Using the carbodiimide method, 3,3'-dithiodipropionyl hydrazide was grafted onto hyaluronic acid with a molecular weight of 800,000 to obtain hydrazide hyaluronic acid with a substitution degree of 30%. The details are as follows: The hyaluronic acid, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide, 3,3'-dithiodipropylene The hydrazide was dissolved in distilled water to prepare a 0.8% hyaluronic acid solution. The pH value of the system was adjusted to 5 with 1mol / L hydrochloric acid. The reaction was stirred at room temperature for 24 hours, and the distilled water was dialyzed with a dialysis bag with a molecular weight cut-off of 3500Da. 2 After days, freeze-drying was performed at minus 20°C for 72 hours to obtain hydrazide hyaluronic acid. Among them, the number of hyaluronic acid repeating units, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, N-hydroxysuccinimide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com