Preparation method of substituted cis-olefin

A cis-olefin, selected technology, applied in pharmaceutical and natural compound chemical intermediates and related chemical fields, can solve the problems of non-reusable, difficult separation and recovery, high price, etc., achieve reduced catalytic effect, simple operation and post-processing , The effect of high product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

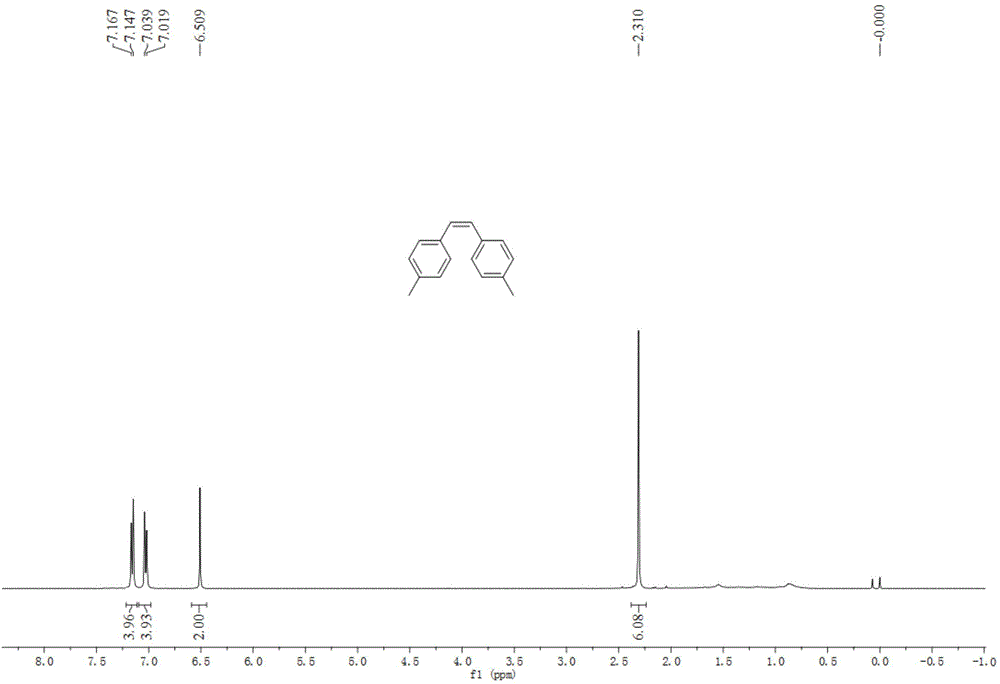

[0023] Embodiment 1: Synthesis of (Z)-1-(4-styrylbenzene)acetyl

[0024] Add diethylamine (5mL), substrate 1-(4-(phenylethynyl)phenyl)acetyl (110.14mg, 0.5mmol), hydrogen (1.0MPa), placed on a magnetic stirrer and reacted at 90°C for 17h, column chromatography (silica gel, 200-300 mesh; developer, petroleum ether) to obtain (Z)-1-(4-styrylbenzene) Acetyl 95.0 mg, yield 86%.

[0025]

[0026] Pale yellow solid; 1 H NMR (CDCl 3 , 400MHz) δ: 7.63(d, J=8.4,2H), 7.14(d, J=8.4,2H), 7.25–7.18(m,5H), 6.73(d, J=12.4,1H), 6.61(d ,J=12.4,1H),2.37(s,3H).

Embodiment 2

[0027] Embodiment 2: Synthesis of (Z)-1-(4-styrylbenzene)acetyl

[0028] Add triethylamine (4mL), substrate 1-(4-(phenylethynyl)phenyl)acetyl (110.14mg, 0.5mmol), hydrogen (1.0MPa), placed on a magnetic stirrer and reacted at 70°C for 20h, column chromatography (silica gel, 200-300 mesh; developer, petroleum ether) to obtain (Z)-1-(4-styrylbenzene) Acetyl 80.1 mg, yield 72%.

[0029]

[0030] Pale yellow solid; 1 H NMR (CDCl 3 , 400MHz) δ: 7.63(d, J=8.4,2H), 7.14(d, J=8.4,2H), 7.25–7.18(m,5H), 6.73(d, J=12.4,1H), 6.61(d ,J=12.4,1H),2.37(s,3H).

Embodiment 3

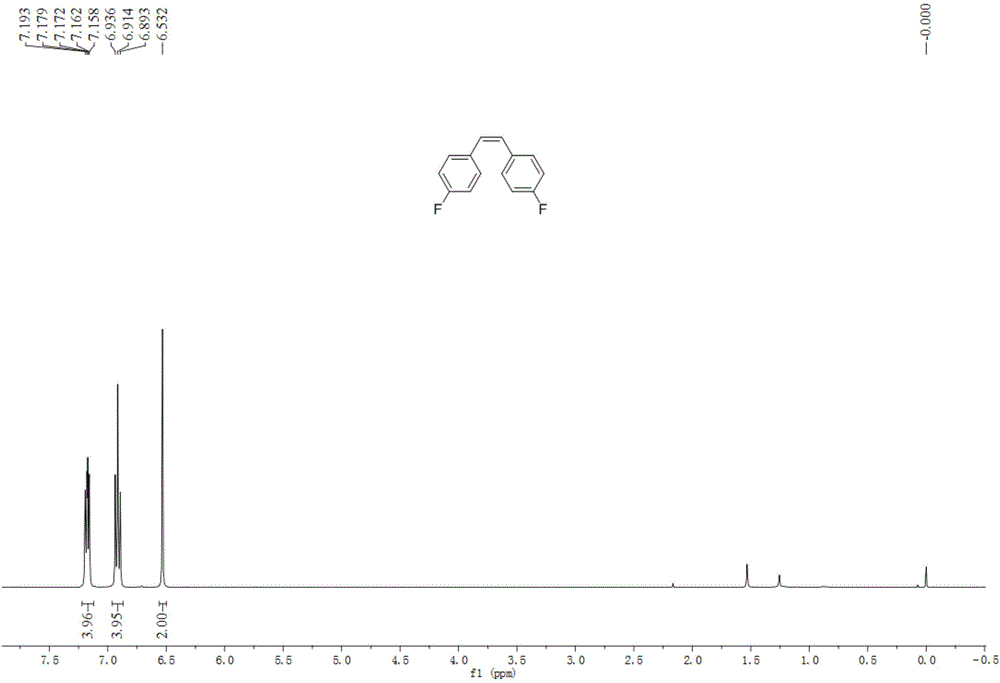

[0031] Example 3: Synthesis of (Z)-1,2-bis(4-fluorophenyl)ethene

[0032] Add pyridine (3mL), substrate 1,2-bis(4-fluorophenyl)acetylene (107.12mg, 0.5mmol), hydrogen (3.0MPa ), placed on a magnetic stirrer at 80°C for 16 hours, column chromatography (silica gel, 200-300 mesh; developer, petroleum ether) to obtain (Z)-1,2-bis(4-fluorophenyl)ethylene 89.0 mg, yield 83%.

[0033]

[0034] white solid; 1 H NMR (CDCl 3 ,400MHz)δ:7.17(m,J=14,4H),6.91(t,J=17.2,4H),6.53(s,2H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com