Low precipitated polyvinyl chloride film structural material for plasticizer and preparation method thereof

A polyvinyl chloride film and structural material technology, applied in chemical instruments and methods, coatings, layered products, etc., can solve the problems of reducing the mobility of plasticizers, limiting application fields, increasing processing difficulty, etc., and achieves excellent inhibition Precipitation, improving compatibility and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

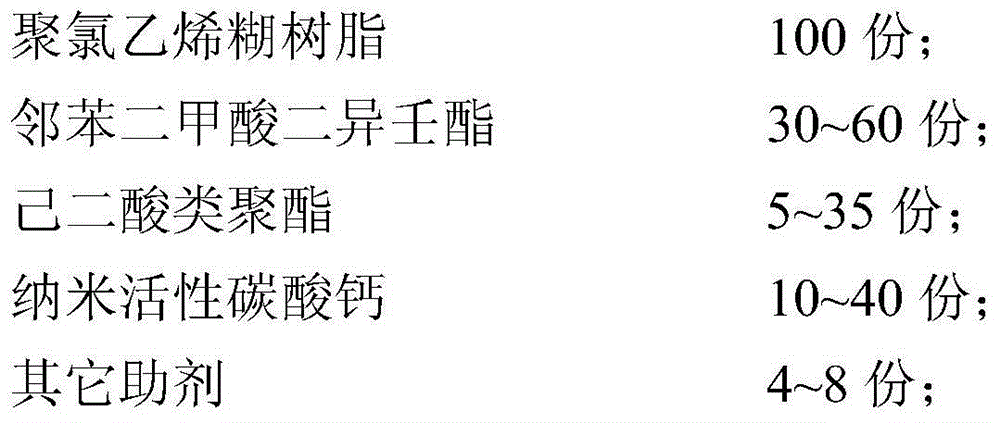

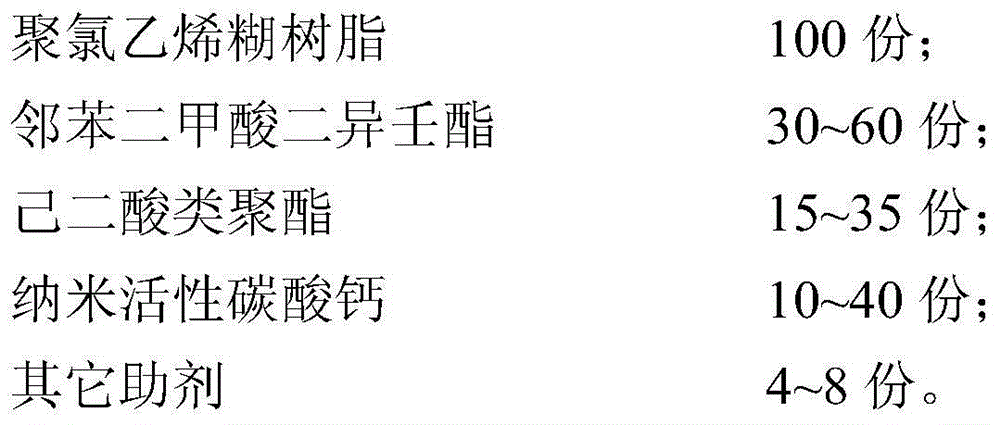

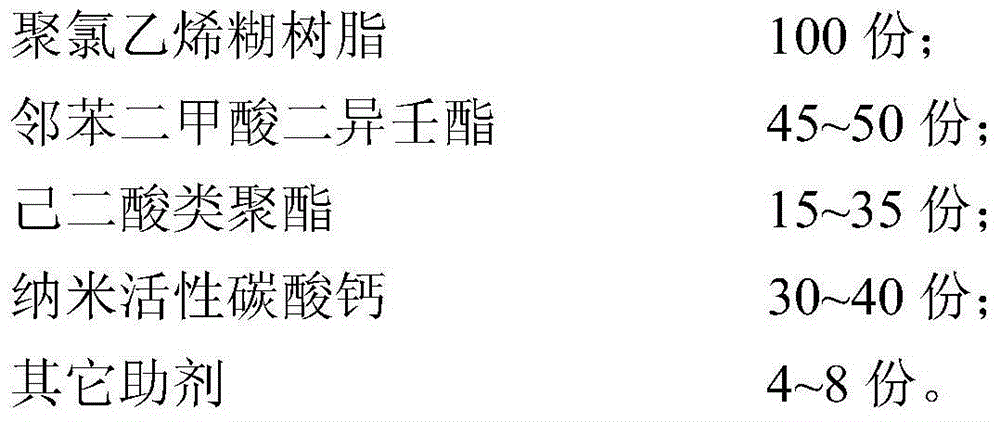

Method used

Image

Examples

Embodiment 1

[0041] 30 parts of nano-active calcium carbonate (XF-6018, Shanghai Huaming High-Tech Co., Ltd.) and 50 parts of diisononyl phthalate (DINP, Jiaxing Xiandao Import and Export Co., Ltd.) were loaded into the mixer , stirred at a speed of 900r / min for 45min to obtain nano-calcium slurry; the first coating slurry was to apply 100 parts of polyvinyl chloride paste resin (P-450, Shanghai Chlor-Alkali Chemical Co., Ltd. ), 2.5 parts of barium-zinc stabilizer (CH601, Shanghai Jinshang Chemical Co., Ltd.), 3.5 parts of crosslinking agent (VP202, Zhongshan Dongling Chemical Co., Ltd.), 5 parts of adipic acid polyester (W8000, under The same) is added to the nano-calcium slurry and stirred at a speed of 900r / min for 45min; the second coating slurry is made of 100 parts of polyvinyl chloride paste resin, 2.5 parts of barium zinc stabilizer, and 5 parts of adipic acid polyester , 30 parts of nano-active calcium carbonate, 1.5 parts of ultraviolet absorber (UV531, Yuyao Jinghai Chemical Pi...

Embodiment 2

[0043] 30 parts of nano-active calcium carbonate and 50 parts of diisononyl phthalate are packed into a mixer, and stirred at a speed of 900r / min for 45 minutes to obtain nano-calcium slurry; Vinyl chloride paste resin, 2.5 parts of barium zinc stabilizer, 3.5 parts of crosslinking agent, 10 parts of adipic acid polyester are added to the nano-calcium slurry, and stirred at a speed of 900r / min for 45min; the second coating slurry is 100 parts of polyvinyl chloride paste resin, 2.5 parts of barium zinc stabilizer, 10 parts of adipic acid polyester, 30 parts of nano-active calcium carbonate, 1.5 parts of ultraviolet absorber, 50 parts of phthalic acid Diisononyl esters were mixed and stirred for 45 minutes at a speed of 900 r / min; the coating slurry was loaded into a PVC coating production line to make a polyvinyl chloride film structural material.

Embodiment 3

[0045] 30 parts of nano-active calcium carbonate and 45 parts of diisononyl phthalate are packed into a mixer, stirred at a speed of 900r / min for 45min to obtain nano-calcium slurry; Add vinyl chloride paste resin, 2.5 parts of barium zinc stabilizer, 3.5 parts of crosslinking agent, and 15 parts of adipic acid polyester into the nano-calcium slurry, and stir for 45 minutes at a speed of 900r / min; the second coating slurry is 100 parts of polyvinyl chloride paste resin, 2.5 parts of barium zinc stabilizer, 15 parts of adipic acid polyester, 30 parts of nano-active calcium carbonate, 1.5 parts of ultraviolet absorber, 45 parts of phthalic acid Diisononyl esters were mixed and stirred for 45 minutes at a speed of 900 r / min; the coating slurry was loaded into a PVC coating production line to make a polyvinyl chloride film structural material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com