Epoxy low-polyether glyceride plasticizer and preparation method thereof

A technology of glyceride and oligoether, which is applied in the field of epoxy oligoether glyceride plasticizer and its preparation, can solve the problems of low molecular weight and easy migration, achieve high flash point, control the degree of polymerization, and high resistance to migration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

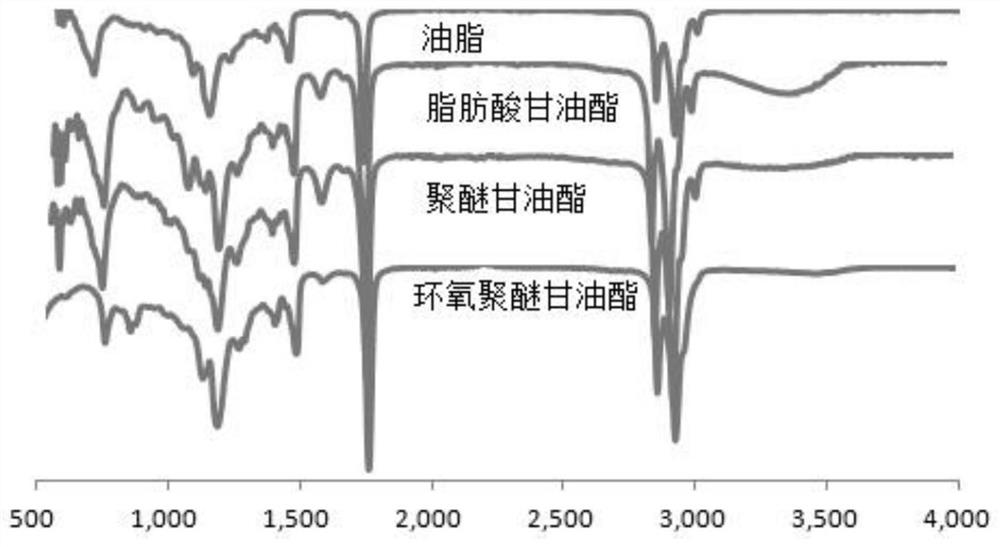

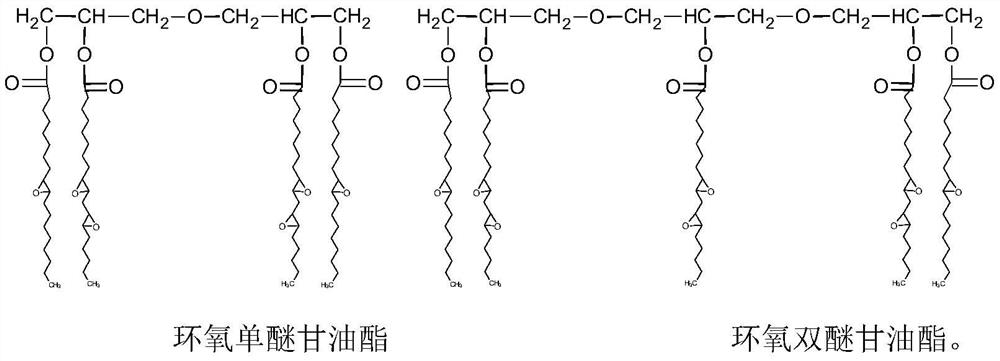

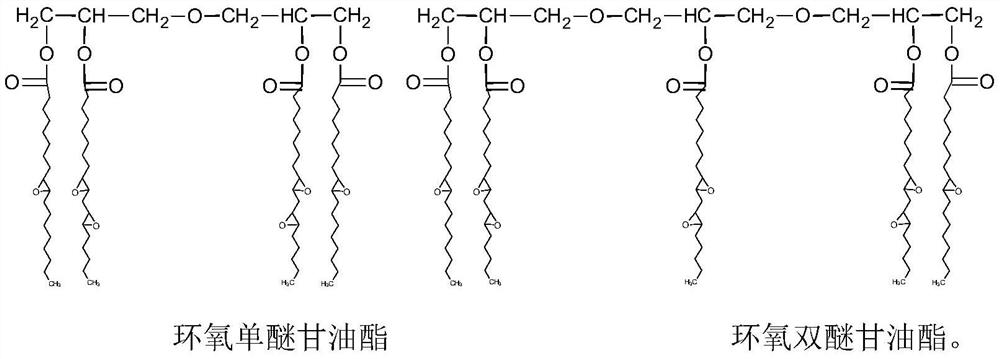

Method used

Image

Examples

Embodiment 1

[0024] Raw materials: soybean oil, glycerin, sodium hydroxide, formic acid, hydrogen peroxide, concentrated sulfuric acid;

[0025] Soybean oil and glycerin are mixed in a ratio of 2:1 and put into the reactor, adding sodium hydroxide accounting for 1% of the raw oil mass, heating up to 190°C under nitrogen protection, and reflux reaction for 8 hours; then add 0.5 % of the catalyzer, use a distillation unit instead and increase the reaction temperature to 250°C for etherification to produce anhydrous. At this time, the product is a mixture rich in monoether glycerides and diether glycerides (if etherified Not completely can be blocked with acetic anhydride, the same below); After conventional operations such as neutralization and water washing, add formic acid accounting for 10% to 50% of the mass of oligoether glycerides and concentrated sulfuric acid accounting for 0.5% to 1% by mass, Heating to 40-60°C, adding 0.9-1.4 times of hydrogen peroxide dropwise, finishing the dripp...

Embodiment 2

[0027] Raw materials: rapeseed oil, glycerin, potassium hydroxide, 3-chloroperoxybenzoic acid, dichloromethane;

[0028] Rapeseed oil and glycerin are mixed and put into the reactor according to the ratio of the amount of substances of 1.6:1, adding potassium hydroxide accounting for 1.2% of the mass of the raw oil, heating up to 180°C under the protection of nitrogen, and refluxing for 10 hours; then adding 0.6% catalyst, use a distillation device instead and increase the reaction temperature to 250 ° C to produce anhydrous etherification. At this time, the product is a mixture rich in monoether glycerides and diether glycerides; After conventional operations such as mixing and washing with water, add the methylene chloride solution of 3-chloroperoxybenzoic acid dropwise at room temperature. Epoxy oligoether glyceride products can be obtained through other processes.

Embodiment 3

[0030] Raw materials: catalpa oil, glycerin, potassium hydroxide, formic acid, hydrogen peroxide, p-toluenesulfonic acid;

[0031] Catalpa oil and glycerin are mixed according to the ratio of the amount of substances to 3:2 and put into the reactor, adding potassium hydroxide accounting for 1.5% of the mass of the raw oil and fat, heating up to 190°C under the protection of nitrogen, and refluxing for 9 hours; then adding 1 % of the catalyst, use a distillation device instead and increase the reaction temperature to 245°C for etherification to produce anhydrous. At this time, the product is a mixture rich in monoether glycerides and diether glycerides; After conventional operations such as washing with water, add formic acid accounting for 10% to 50% of the mass of oligoether glyceride and p-toluenesulfonic acid accounting for 0.5% to 1% by mass, and add 0.9 to 1.4 times of hydrogen peroxide dropwise when heated to 40 to 60°C , drop it within 40 minutes, then raise the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com