Magnetic heterostructure fiber and preparation method and application thereof

A technology of heterostructures and fibers is applied in the field of preparation of Fe3O4/Ni heterogeneous porous fiber electromagnetic composite materials, which can solve problems such as work that has not yet been reported, and achieve the effects of easy industrial application and promotion, strong magnetic responsiveness and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Firstly, 2mmol ammonium ferrous sulfate, 1mmol sodium lauryl sulfate, 10mL ethylene glycol, and 4mL distilled water were prepared as solution A. Then 1mmol sodium lauryl sulfate, 10mL ethylene glycol, 4mL distilled water and 2.2mmol ammonium oxalate were prepared as solution B. Dissolve solution A and solution B for 30 minutes respectively, then transfer solution B and solution A to a 100mL beaker, and react with magnetic stirring at room temperature for 1 hour, then wash with water and ethanol for six times, and dry at 60°C for 6 hours to obtain the desired fibrous shape. Ferrous oxalate precursor.

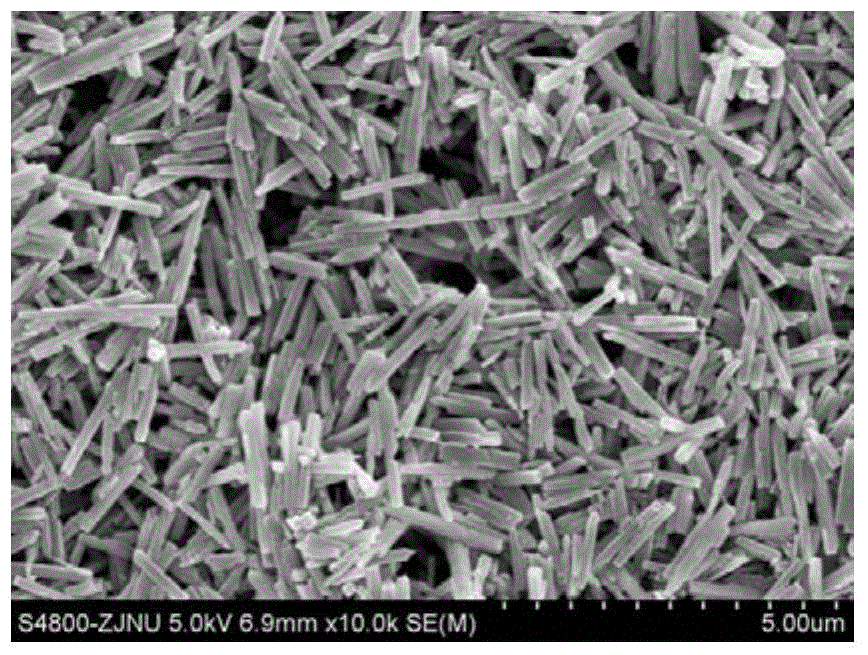

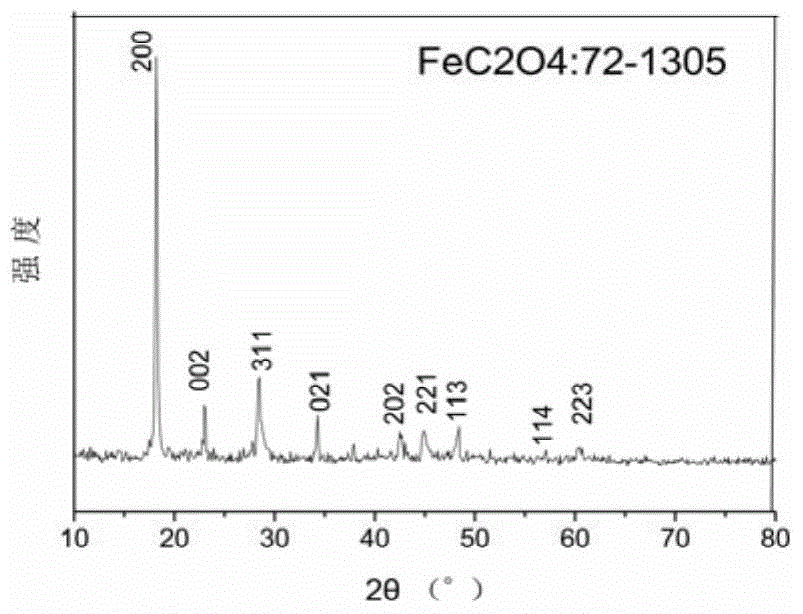

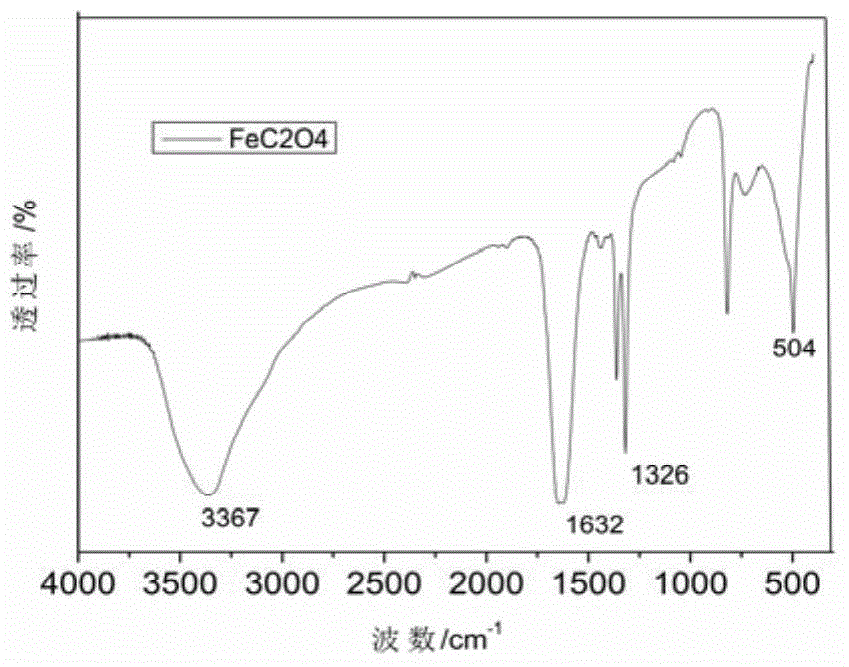

[0042] The morphology observed under the scanning electron microscope, the phase and infrared spectrum of the obtained product are as follows figure 1 , 2 , 3, it can be seen that the product is rod-shaped ferrous oxalate, the rod length is 1.18-1.76 μm; the diameter is 0.14-0.26 μm; the aspect ratio is 6.36-9.77.

Embodiment 2

[0044] Same step as Example 1, but the ratio of the amount of precipitating agent to ferrous ammonium sulfate is 1:2. The morphology of the obtained product observed under the scanning electron microscope is as follows: Figure 4 As shown, it can be seen that the product is rod-shaped ferrous oxalate, the rod length is 2.14-2.79 μm; the diameter is 0.25-0.39 μm; the aspect ratio is 5.49-9.38.

Embodiment 3

[0046] Identical to embodiment 1 step, but the ratio of the amount of substance of precipitating agent and ferrous ammonium sulfate is 2:1. The morphology of the obtained product observed under the scanning electron microscope is as follows: Figure 5 As shown, it can be seen that the product is rod-shaped ferrous oxalate, the rod length is 1.04-1.76 μm; the diameter is 0.14-0.30 μm; the aspect ratio is 5.05-7.84.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com