Micro-fluidic chip used for raw milk body cell counting

A microfluidic chip, raw milk technology, applied in specific-purpose bioreactors/fermenters, biochemical instruments, biomass post-processing, etc. Detect problems such as the distribution of somatic cells, etc., to achieve the effect of improving accuracy and accurate counting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

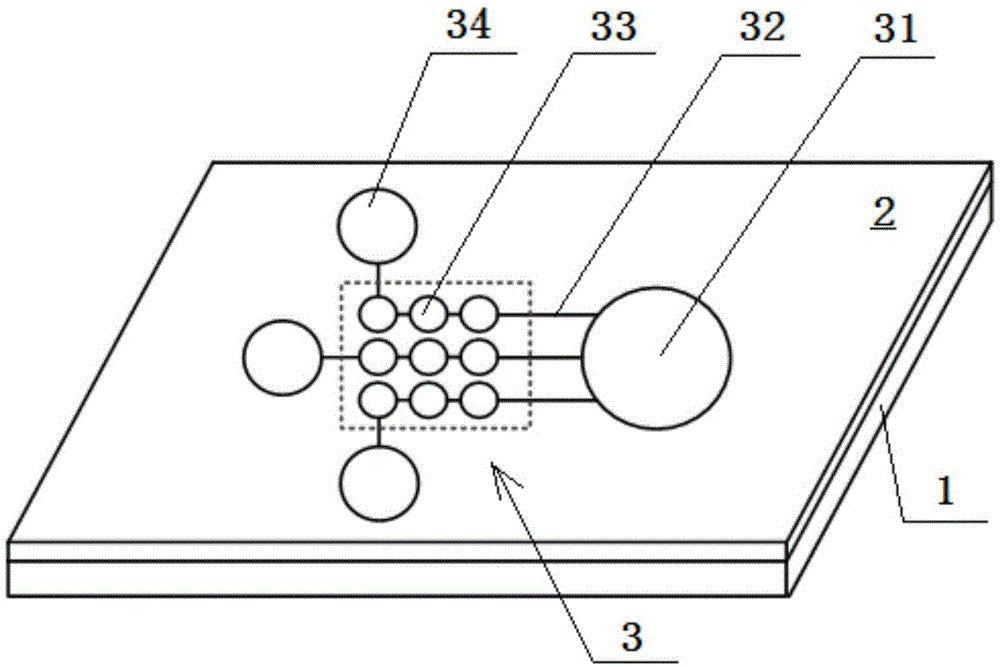

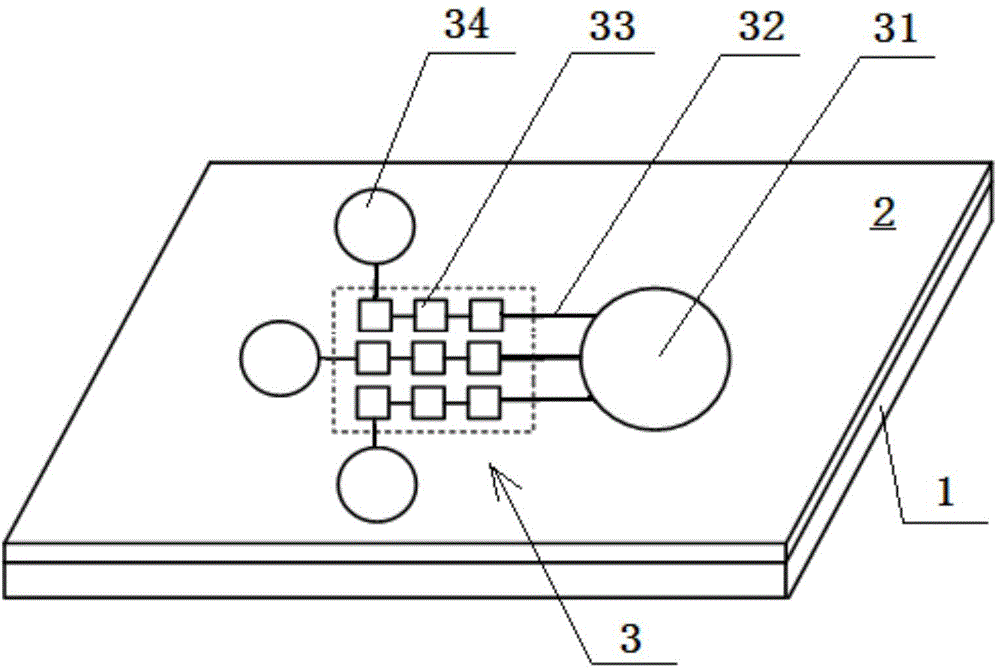

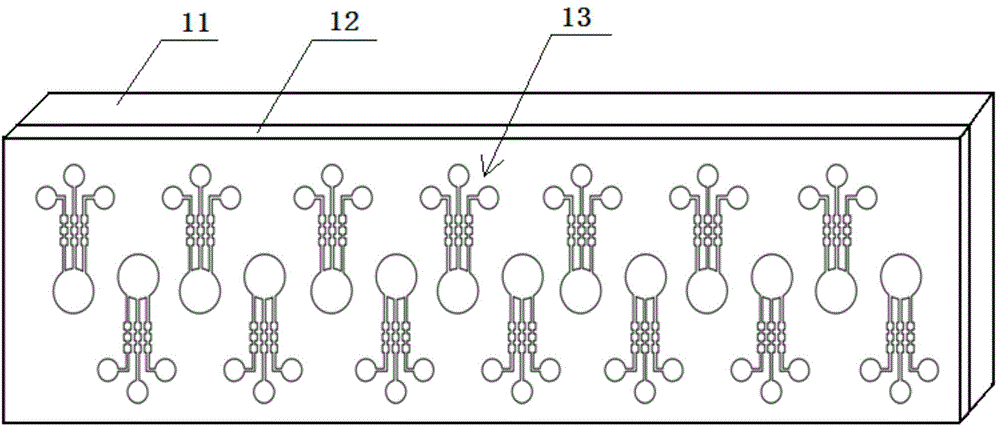

[0042] refer to image 3 Make photo-painted mask negatives, the size of the mask is 70×20mm, and 14 detection units composed of microfluidic channels are distributed. Clean the glass slide, complete the plastic sealing of the photosensitive film and the glass slide, place the mask negative on the photosensitive film, and complete the microstructure after the ultraviolet exposure and development process as a mold to make a microfluidic channel structure. The PDMS prepolymer and the plasticizer were evenly mixed according to the mass ratio of 10:1, then poured into the above-mentioned microfluidic channel, and kept in a constant temperature drying oven at 80°C for 2 hours to complete the curing and obtain the microfluidic channel structure. Use a hole puncher to punch holes at the sample inlet and waste liquid outlet, and then place the microfluidic channel and the clean glass slide substrate in a plasma bonding machine for plasma treatment to complete the microfluidic channel a...

Embodiment 2

[0044] refer to image 3 Make photo-painted mask negatives, the size of the mask is 70×20mm, and 14 detection units composed of microfluidic channels are distributed. Clean the glass slide, and complete the coating process of the SU8 photoresist on the glass slide by using a glue machine, and control the thickness of the photoresist layer to 30um. The mask film is placed on the photosensitive film, and the microstructure after the ultraviolet exposure and development process is used as a mold to make a microfluidic channel structure. The PDMS prepolymer and the plasticizer were evenly mixed according to the mass ratio of 10:1, then poured into the above-mentioned microfluidic channel, and kept in a constant temperature drying oven at 80°C for 2 hours to complete the curing and obtain the microfluidic channel structure. Use a puncher to punch holes at the inlet and the outlet of the waste liquid, and then place the microfluidic channel and the clean acrylic glass substrate in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com