Method for selectively leaching zinc in complex zinc oxide materials at high temperature by adopting ammonium chloride solution

A technology of ammonium chloride solution and zinc oxide, which is applied in the field of zinc extraction by non-ferrous metallurgy hydrometallurgy, can solve the problems of difficult to deal with complex zinc oxide ore of heteropolar ore, and achieve the effect of improving binding ability and inhibiting dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

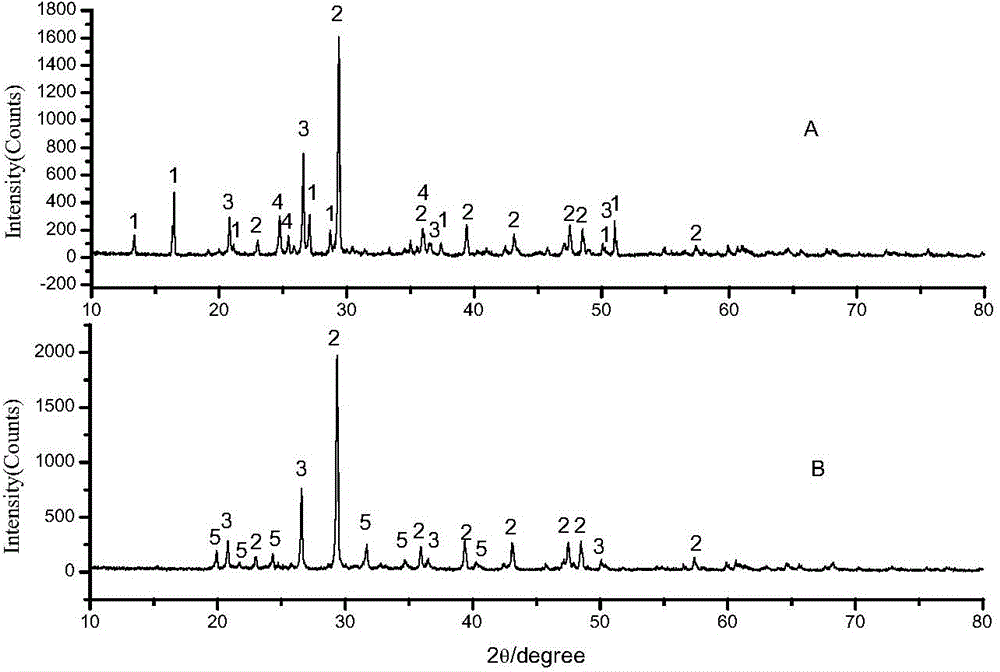

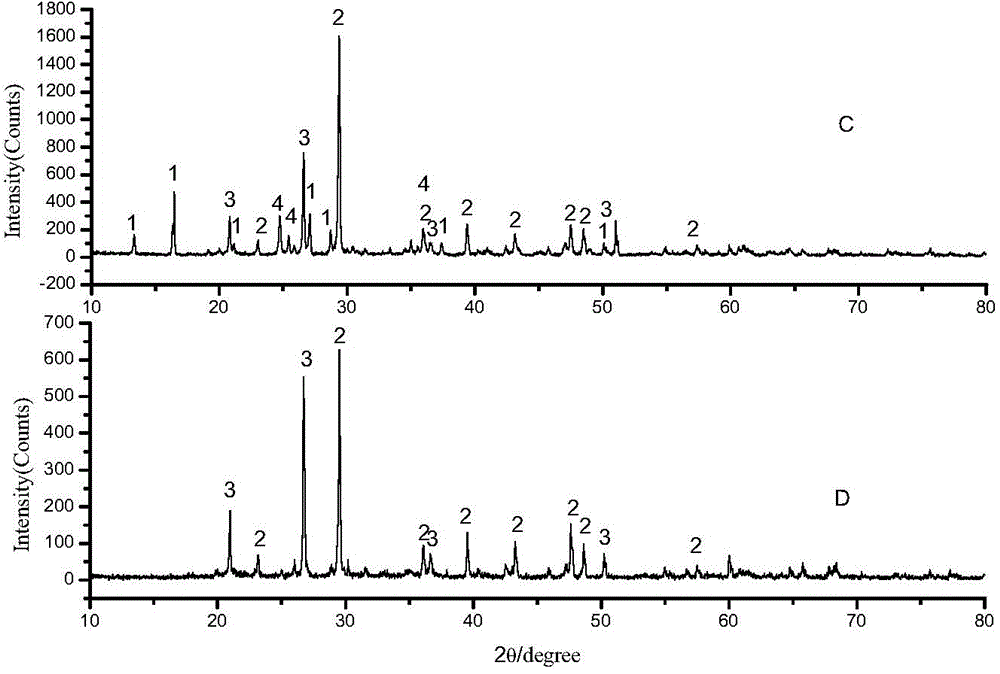

[0022] Take 200g of a certain low-grade zinc oxide ore (its composition is shown in Table 1 and its phase is shown in Table 2), mixed with 5mol / L ammonium chloride solution as the leaching agent, and add them together to the high pressure at a liquid-solid ratio of 5:1mL / g In the kettle, the stirring speed is 300r / min, the leaching time is 1h at a temperature of 150°C, and the leaching rate of zinc is 94.83%. figure 1 (A) and (B) are the XRD patterns of the mine and the leaching slag at 150°C respectively. The gangue impurities in the leaching slag are mainly SiO 2 , CaCO 3 composition.

[0023] Table 1 Zinc oxide ore chemical composition analysis / %

[0024]

[0025] Table 2 Zinc Oxide Zinc Phase Analysis / %

[0026]

Embodiment 2

[0031] Take 200g of a certain low-grade zinc oxide ore (its composition is shown in Table 1 and its phase is shown in Table 2), mixed with 5mol / L ammonium chloride solution as the leaching agent, and add them together to the high pressure at a liquid-solid ratio of 5:1mL / g In the kettle, the stirring speed is 500r / min, the leaching time is 5h at a temperature of 110°C, and the leaching rate of zinc is 92.19%.

Embodiment 3

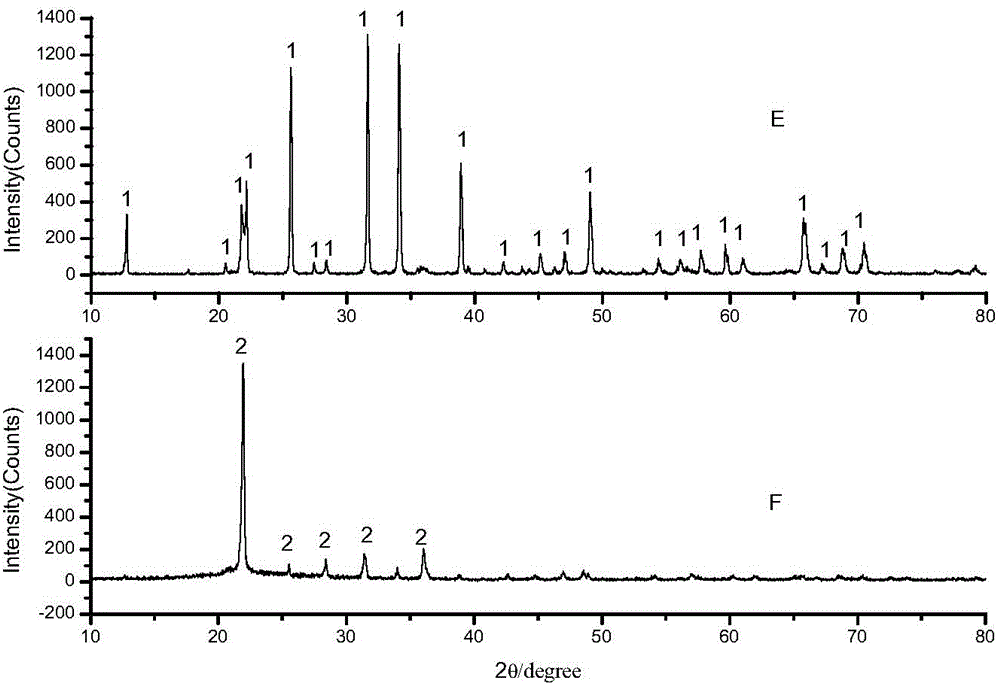

[0036] Take 200g of zinc silicate (the composition is shown in Table 3), mix 6mol / L ammonium chloride solution as leaching agent 1000mL, put them into the autoclave together, stir at 700r / min, and leaching time at 140°C for 1h, zinc The leaching rate is 96.87%, image 3 (E), (F) are the XRD patterns of zinc silicate and its leaching residue. It can be seen from the figure that zinc silicate, which is difficult to be leached by ammonia method and ammonia-ammonium salt method, can be leached in this system.

[0037] Table 3 Elemental analysis results of zinc silicate / %

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com