High-precision wire electric discharge machining machine

A technology of electric discharge wire and cutting machine, applied in the direction of electrode manufacturing, electric processing equipment, metal processing equipment, etc., can solve the problem of affecting the fineness of cutting products and the smoothness of cutting, the long distance from the wire drum to the processing center, and the cutting of molybdenum wire The problems such as the thinning of wire diameter can be solved, and the effect of improving operation efficiency, stable operation and improving quality can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further elaborated below in conjunction with accompanying drawing.

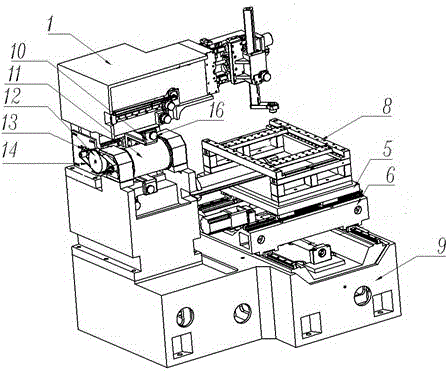

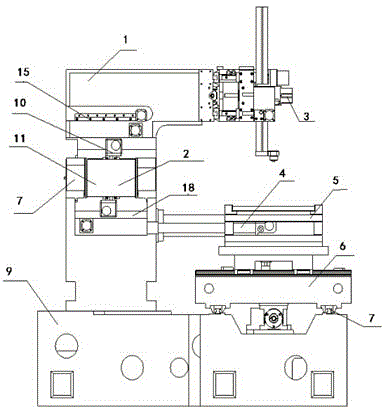

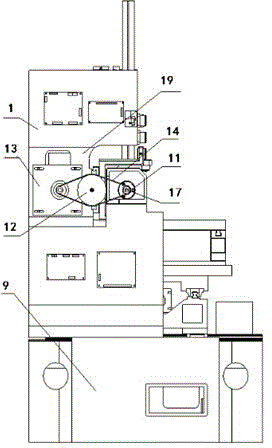

[0022] Such as figure 1 , figure 2 and image 3 As shown, a high-precision wire electric discharge machine includes a bed 9, a wire transport mechanism, a wire frame, a workbench, machine tool electrical appliances and several parts of a numerical control system, wherein the wire transport mechanism includes a wire transport motor 13, a wire storage Tube 11, screw mandrel pair, synchronous wheel 12 and synchronous belt 14, wire transport motor 13 drives storage silk tube 11 to do rotary motion, drives synchronous wheel 12 to rotate by synchronous belt 14 simultaneously.

[0023] The wire frame includes a column 1 fixed on the bed 9 and an upper arm 3 connected with the column 1, a lower arm 4 and several guide wheels 16, and a cavity 19 is provided in the column 1.

[0024] The workbench 8 includes the upper carriage 5, the lower carriage 6, the carriage motor, the carriage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com