Papermaking pulping black liquor treatment system

A technology for pulping black liquor and treatment system in papermaking, which is applied in processing wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Excessive discharge of sewage treatment and other problems, to achieve the effect of small footprint, saving power consumption and operating costs, and saving investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

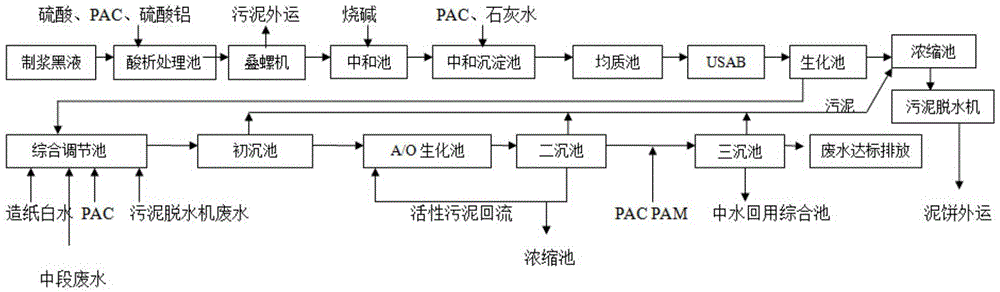

[0036] Such as figure 1 A papermaking pulping black liquor treatment system is shown, which includes a papermaking pulping black liquor collection system, an acid precipitation treatment tank, a neutralization tank, a neutralization sedimentation tank, a homogeneous tank, and an upflow anaerobic sludge bed , biochemical tank, comprehensive adjustment tank, sedimentation tank, A / O biochemical tank, secondary sedimentation tank, tertiary sedimentation tank and sewage discharge system, the described papermaking pulping black liquor collection system is connected to the acid analysis treatment by pipelines Add 98% industrial sulfuric acid to the acid analysis pool, and the dosage is based on the pH of the water quality to 3-4.5. Add flocculant PAC in the acid analysis and settling tank, the preparation concentration is 15%, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com