Immersion liquid limiting mechanism

A technology of limiting mechanism and immersion liquid, which is applied in the direction of photolithography exposure device, microlithography exposure equipment, etc., to avoid excessive impact force, solve the problem of droplet splashing, and the effect of large repulsion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

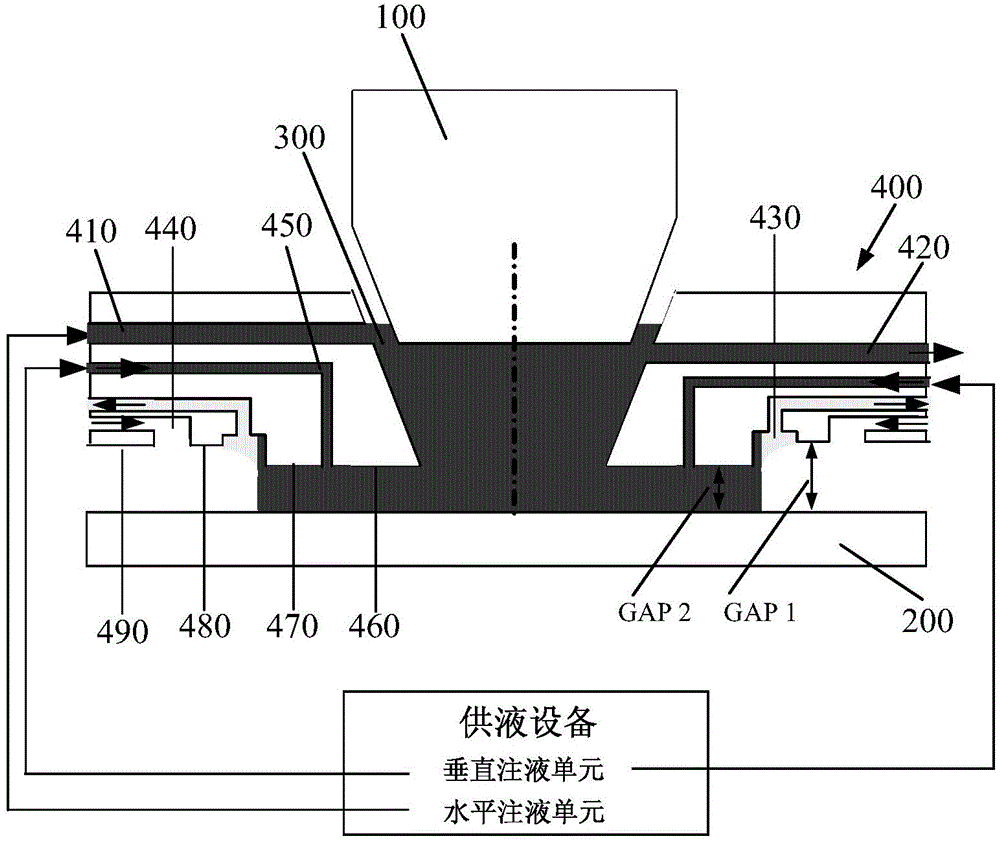

[0062] Preferably, please focus on the reference Figure 7 , the control system of the vertical liquid supply channel 450 includes a sensor 451, a closed-loop control unit 452 and a flow adjustment unit. In this embodiment, the flow adjustment unit uses a magnetic levitation centrifugal pump 453. When in use, the magnetic levitation centrifugal pump 453 can With return channel, such as Figure 7 shown in . Both the sensor 451 and the flow regulating unit are disposed in the vertical liquid supply channel 450 , and the sensor 451 and the flow regulating unit are respectively connected to the closed-loop control unit 452 . Specifically, when the distance between the second plane 470 and the upper surface of the silicon wafer 200 decreases (that is, when there is a risk of collision between the immersion liquid limiting mechanism 400 and the silicon wafer 200 or the workpiece table), the liquid injection resistance of the vertical liquid supply channel 450 ( Load) increases, if...

Embodiment 2

[0064] Preferably, please focus on the reference Figure 8 , the difference between this embodiment and Embodiment 1 is that the flow regulating unit adopts a two-way flow regulating valve 454. When in use, the two-way flow regulating valve 454 can be provided with a return channel, such as Figure 8 shown in . Specifically, the valve body of the two-way flow regulating valve 454 is made of high-purity PFA or PTFE (polytetrafluoroethylene) that is resistant to chemical corrosion and free from pollution such as metals and particles. The contact part of 300 is required to be made of high-purity PFA that is resistant to chemical corrosion and free from pollution such as metals and particles; the sensor 451 collects the flow velocity or pressure of the immersion liquid 300 in the vertical liquid supply channel 450, and feeds back to the closed-loop control unit 452, the closed-loop control unit 452 electronically adjusts the driver connected to the two-way flow regulating valve 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com