Laser resistance welding power module

A technology of power modules and solder resistance, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of reduced flexibility, loss of solder resistance, and falling off, etc., and achieves the effect of reliable method, strong flexibility and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

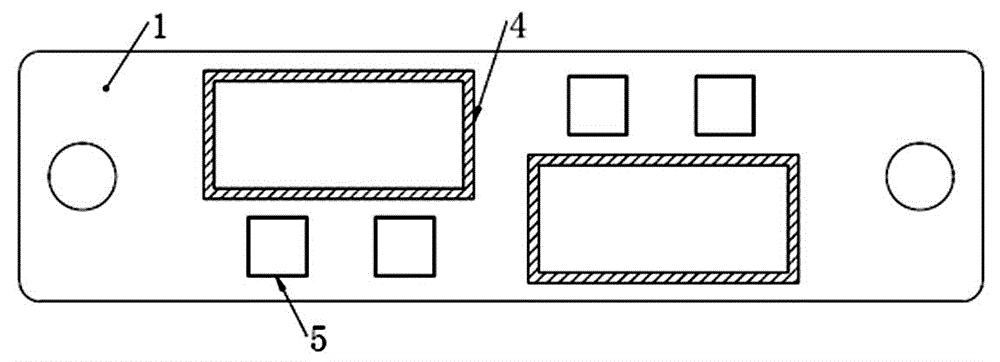

[0020] figure 1 According to the layout design of the power module, it is a style of laser soldering on the copper substrate 1 . The solder resist patterns 4 and 5 formed by laser etching on the copper substrate 1 include a rectangular wire frame 4 with a wire diameter of 1 mm for DBC soldering and a rectangular wire frame 5 with a wire diameter of 0.1 mm for chip soldering.

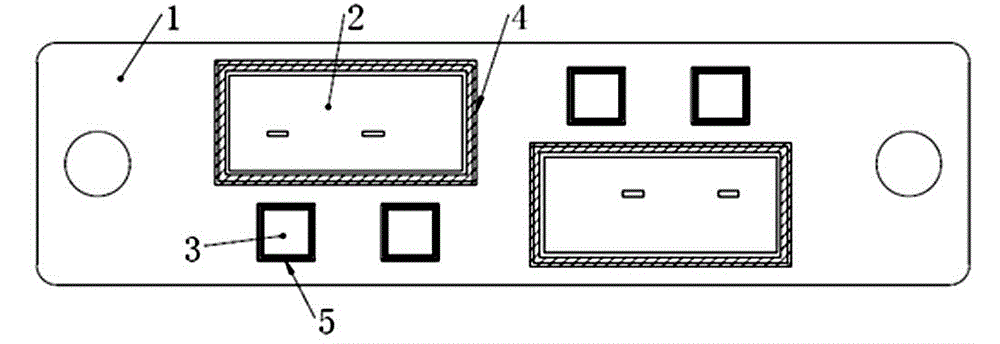

[0021] figure 2 It is a semi-finished power module with a chip 3 and a copper-clad ceramic substrate (DBC) 2 mounted thereon.

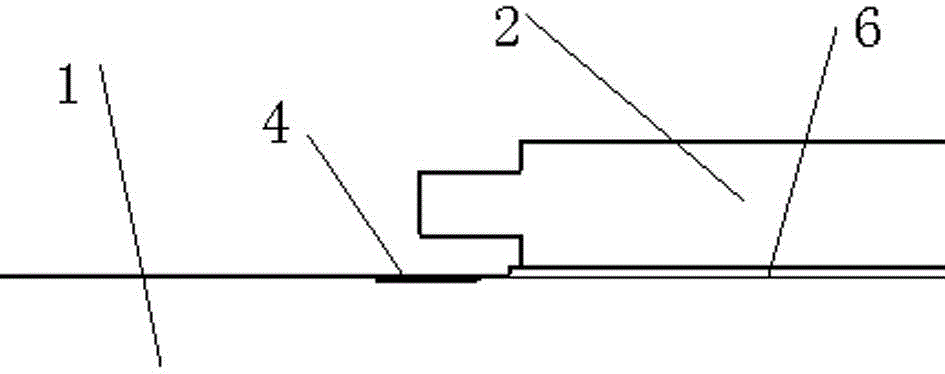

[0022] according to image 3 As shown, the minimum distance between the solder 6 and one side of the solder resist area 4 is about 0.3 mm, and the minimum distance between the edge of the lower copper layer of the copper-clad ceramic substrate (DBC) 2 and the solder resist area 4 is about 0.4 mm.

[0023] according to Figure 4 As shown, the minimum single-side distance between the solder 7 and the solder resist area 5 is about 0.1 mm, and the minimum single-side distance b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com