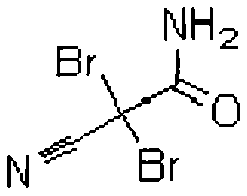

DBNPA-containing disinfectant composition and preparation method thereof

A composition and disinfectant technology, applied in botany equipment and methods, disinfectants, biocides, etc., can solve the problems of storage stability of DBNPA, expansion of water body organic pollution, increase of raw material cost, etc., to reduce high COD problems, good antifreeze performance and strong solubility aiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

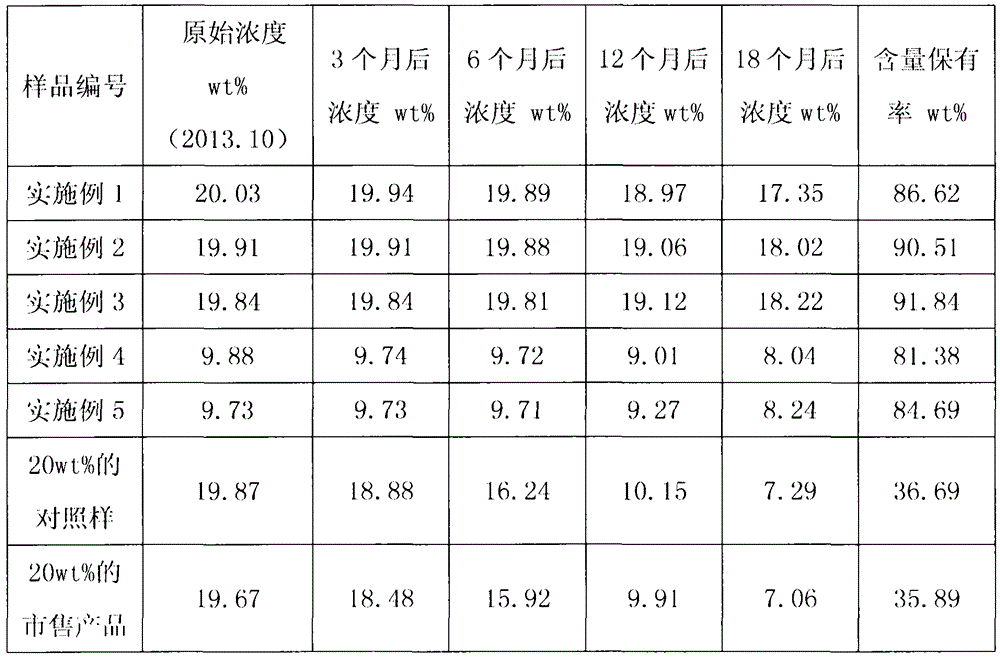

Embodiment 1

[0015] A disinfectant composition containing DBNPA, comprising: DBNPA: 20wt%, tetraethylene glycol: 25wt%, 1,3-butanediol: 12wt%, deionized water: 40.46wt%, sodium bromide: 1wt%, cyano Acetic acid: 1.5 wt%, hydrochloric acid: 0.04 wt%.

[0016] The specific preparation method: add 250kg of tetraethylene glycol and 120Kg of 1,3-butanediol into the reaction kettle and stir for 10 minutes. Deionized water, under the condition of stirring, slowly add sodium bromide 10Kg, cyanoacetic acid 15kg and industrial grade concentrated hydrochloric acid 400ml. Stir for 10 minutes after the addition, and the kettle temperature is 30°C at this time. Slowly add DBNPA under stirring conditions to a total of 200Kg (control the feeding time at about 20 minutes), stir for 55 minutes after adding, until it is completely dissolved and uniform, take a sample to measure the pH value to 3.6, and finally add the remaining 204.6Kg of deionized water, stir After 15 minutes, take a sample and measure the...

Embodiment 2

[0018] A disinfectant composition containing DBNPA, comprising: DBNPA: 20wt%, tetraethylene glycol: 25wt%, 1,3-butanediol: 14wt%, deionized water: 39.92wt%, sodium bromide: 0.5wt%, 2 , 2-dibromomalonamide 0.5wt%, sulfamic acid: 0.08wt%.

[0019] Specific preparation method: Add 250kg of tetraethylene glycol and 140Kg of 1,3-butanediol into the reaction kettle and stir for 10 minutes. The temperature of the kettle is 27°C, add 200Kg of deionized water, and slowly add bromine while stirring. Sodium chloride 5Kg, 2,2-dibromomalonamide 5kg and industrial grade sulfamic acid 800g. Stir for 10 minutes after the addition, and the kettle temperature is 32°C at this time. Slowly add DBNPA under stirring conditions to a total of 200Kg (control the feeding time at about 20 minutes), stir for 55 minutes after the addition, until it is completely dissolved and uniform, take a sample to measure the pH value to 3.8, and finally add the remaining 199.2Kg of deionized water, stir After 15 mi...

Embodiment 3

[0021]A disinfectant composition containing DBNPA, comprising: DBNPA: 20wt%, tetraethylene glycol: 19wt%, 1,3-butanediol: 20wt%, deionized water: 39.45wt%, 2,2-dibromomalonamide : 0.5wt%, cyanoacetic acid: 1.0wt%, hydrochloric acid: 0.05wt%.

[0022] Specific preparation method: Add 190kg of tetraethylene glycol and 200Kg of 1,3-butanediol into the reaction kettle and stir for 10 minutes. The temperature of the kettle is 25°C. Add 200Kg of deionized water. While stirring, add 2, 5Kg of 2-dibromomalonamide, 10Kg of cyanoacetic acid and 500ml of industrial grade hydrochloric acid. Stir for 10 minutes after the addition, and the temperature of the kettle is 29°C. Slowly add DBNPA under stirring condition to a total of 200Kg (control the feeding time at about 20 minutes), stir for 55 minutes after adding, until it is completely dissolved and uniform, take a sample to measure the pH value to 3.5, and finally add the remaining 194.5Kg of deionized water, stir After 15 minutes, tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com