Method for reducing heavy metal emission in livestock and poultry manure

A technology for livestock and poultry manure and heavy metals, which is applied in the field of animal husbandry, can solve the problems of indigestion and utilization of animals, lack of good solutions, and insufficient utilization of iron, and achieve the effects of reducing gastric ulcer disease, reducing the discharge of heavy metals, and improving palatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

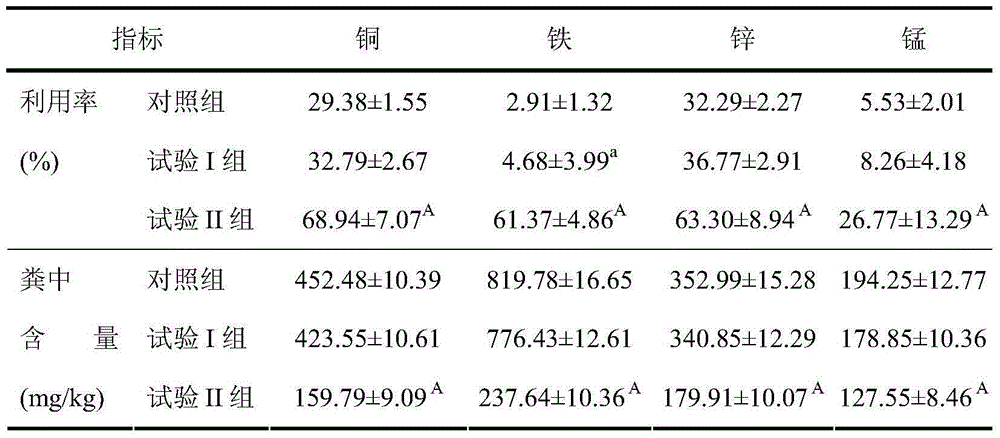

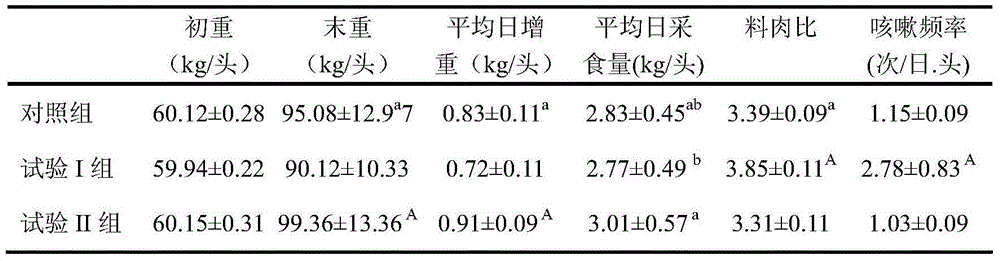

[0020] According to the principle of similar body weight, age and sex ratio, 60 Du×Da×Chang three-way hybrid growth pigs with a body weight of 60.10±0.50kg were selected and randomly divided into control group, test group I and test group II, with 4 pigs in each group Repeat, 5 heads per repetition. The diet of the control group was a corn-soybean meal type dry powder diet with a feed crushing particle size of 0.90 mm, the diet of the test group I was a corn-soybean meal type dry powder diet with a feed crushing particle size of 0.70 mm, and the test group II was a feed crushing particle size 0.70mm corn-soybean meal type fermented wet feed diet. The formal trial period is 42 days. Start adding 0.3% Cr in feed before end 3d 2 o 3 , Collect feces samples continuously for 3 days in repeated units, and use them to determine the content of copper, iron, zinc, and manganese in pig manure and the utilization rate of copper, iron, zinc, and manganese in corn, soybean meal, and bra...

example 2

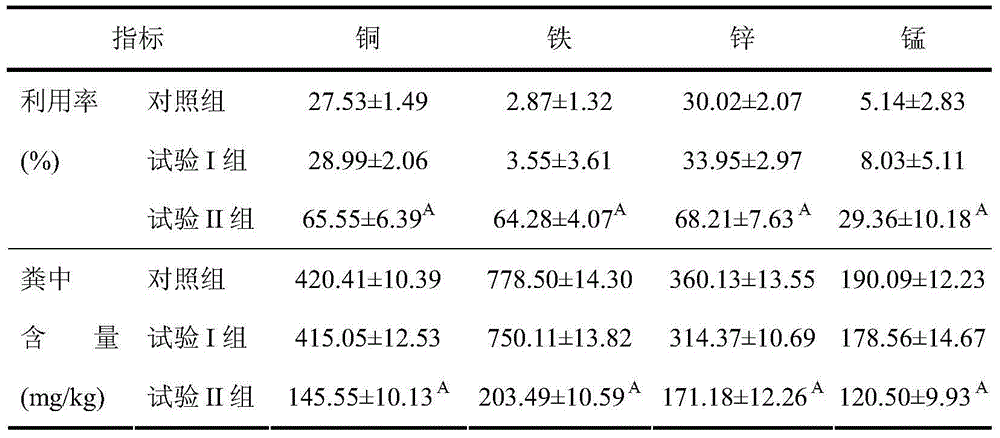

[0036] According to the principle of similar body weight, age and sex ratio, 75 Audelai growing and finishing pigs with a body weight of 60.10±0.50kg were selected and randomly divided into the control group, the test group I and the test group II, and each group had 5 repetitions. 5 heads. The diet of the control group was a corn-soybean meal type dry powder diet with a feed crushing particle size of 1.50 mm, the diet of the test group I was a corn-soybean meal type dry powder diet with a feed crushing particle size of 0.40 mm, and the test group II was a feed crushing particle size 0.40mm corn-soybean meal fermented wet diet. The formal trial period is 56 days. Start adding 0.3% Cr in feed before end 3d 2 o 3 , Feces samples were collected continuously for 3 days in repeated units, and used to determine the content of copper, iron, zinc, and manganese in pig manure and the utilization rate of copper, iron, zinc, and manganese in corn, wheat, soybean meal, rapeseed meal, a...

example 3

[0049]According to the principle of similar body weight, age and sex ratio, 60 Topek fattening pigs with a body weight of 60.10 ± 0.50 kg were selected and randomly divided into control group, test group I and test group II, with 4 repetitions in each group and 5 repetitions in each group. head. The diet of the control group was a corn-soybean meal type dry powder diet with a crushed particle size of 1.00 mm, the diet of the test group I was a corn-soybean meal type dry powder diet with a crushed particle size of 0.60 mm, and the test group II was a corn-soybean meal type dry powder diet with a crushed particle size of 0.60 mm. mm corn-soybean meal-based fermented wet-fed diet. The formal trial period is 42 days. Start adding 0.3% Cr in feed before end 3d 2 o 3 , Collect feces samples continuously for 3 days in repeated units, and use them to determine the content of copper, iron, zinc, and manganese in pig manure and the utilization rate of copper, iron, zinc, and manganes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com