Method for preparing conjugated molecular hybridization semiconductor photocatalytic material by using mechanochemistry

A technology of photocatalytic materials and conjugated molecules, which is applied in the field of inorganic materials, can solve problems such as difficult to achieve large-scale production, cumbersome separation and treatment steps, and complicated process, so as to avoid the generation of waste liquid, improve photocatalytic activity and generate visible light Activity, the effect of simplifying the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

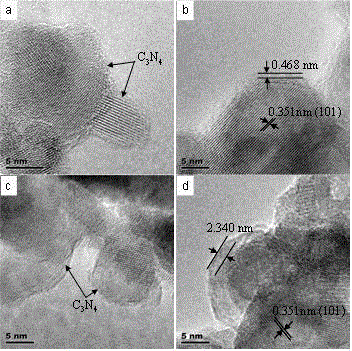

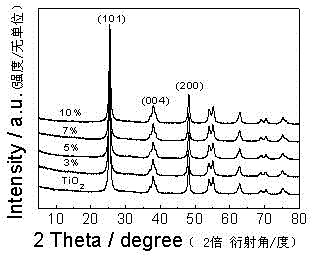

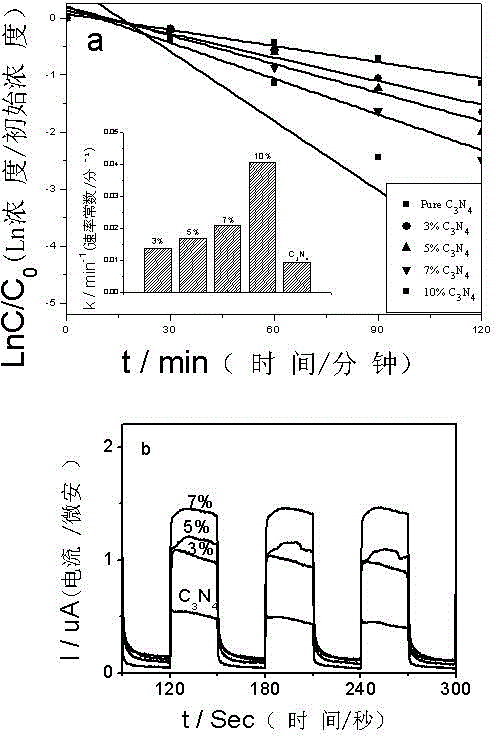

[0027] Anatase nano-titanium dioxide (TiO 2 ) with conjugated molecular graphitic carbon nitride (g-C 3 N 4 ) Weighed according to different mass ratios, the doping source g-C 3 N 4 The mass fractions are respectively 3% to 5% of the total mass of raw materials. Grind and mix evenly in an agate mortar, add it to a 50 ml agate ball mill jar at a ball / material mass ratio of 10:1, and mill in a planetary high-energy ball mill at a speed of 350 rpm for 3 hours to obtain different proportions of g-C 3 N 4 / TiO 2 Hybrid photocatalytic materials. Structural characterization was carried out, and methylene blue was used as a probe compound to evaluate its visible and ultraviolet photocatalytic activity. The results showed that g-C 3 N 4 / TiO 2 The visible light catalytic activity of pure g-C 3 N 4 about 3 times that of pure TiO under UV light 2 The corresponding photocurrents are about 2.5 times and 1.5 times respectively.

Embodiment 2

[0029] Nano-zinc oxide (ZnO) and conjugated molecule g-C 3 N 4 Weigh according to different mass ratios, where g-C 3 N 4 The mass fractions are respectively 3% to 5% of the total mass of raw materials. Grind and mix evenly in an agate mortar, put them into a 50 ml agate ball mill jar at a ball / material mass ratio of 20:1, and mill in a ball mill at a speed of 450 rpm for 2 hours to obtain different proportions of g-C 3 N 4 / ZnO hybrid photocatalytic materials. Its structure was characterized, and its photocatalytic activity was evaluated at room temperature with methylene blue as the probe compound. The results showed that under visible light irradiation g-C 3 N 4 / ZnO photocatalytic activity is pure g-C 3 N 4 Nearly 3 times of that, the corresponding photocurrent is about 2.5 times, and the catalyst performance is stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com