Preparation method of (S)-3-hydroxytetrahydrofuran and (R)-3-hydroxytetrahydrofuran

A technology of hydroxytetrahydrofuran and dihydroxy, which is applied in the field of preparation of five-membered heterocyclic compounds, can solve the problems of short reaction steps, expensive raw materials, and low yield, and achieve the effects of short reaction steps, simple process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

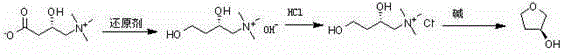

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of (S)-2,4-dihydroxy-N,N,N-trimethylbutylamine base

[0023] Add 30g (0.186mol) (S)-carnitine to a four-necked flask equipped with a thermometer, stirring, and an external bath, and then add 300ml of tetrahydrofuran. 0.28mol) (1.5eq) sodium borohydride, after adding, return to room temperature for reaction, after the reaction, add 16.8g of water to quench the reaction, evaporate THF and water under reduced pressure, then add 300ml of ethyl acetate, stir, and filter with suction , The purity of the product in the filtrate: 75.8%, the filtrate is directly used for the next step of salt formation.

[0024] (2) Preparation of (S)-2,4-dihydroxy-N,N,N-trimethylbutylamine hydrochloride

[0025] Put the ethyl acetate solution of (S)-2,4-dihydroxy-N,N,N-trimethylbutylamine base prepared above in a four-necked flask, and slowly add hydrogen chloride (0.242mol ) (1.3eq) of ethyl acetate solution, the ice-water bath controlled the temperature not to exceed 40°C, ...

Embodiment 2

[0030] (1) Preparation of (S)-2,4-dihydroxy-N,N,N-trimethylbutylamine base

[0031] Add 30g (0.186mol) (S)-carnitine to a four-necked flask equipped with a thermometer, stirring, and an external bath, and then add 300ml of tetrahydrofuran. 0.558mol) (3eq) sodium borohydride, after adding, return to room temperature for reaction, after the reaction, add 16.8g of water to quench the reaction, evaporate THF and water under reduced pressure, then add 300ml of ethyl acetate, stir, and suction filter, Product purity in the filtrate: 74.1%, and the filtrate is directly used for the next step of salt formation.

[0032] (2) Preparation of (S)-2,4-dihydroxy-N,N,N-trimethylbutylamine hydrochloride

[0033] Put the ethyl acetate solution of (S)-2,4-dihydroxy-N,N,N-trimethylbutylamine base prepared above in a four-necked flask, and slowly add hydrogen chloride (0.242mol ) (1.3eq) of ethyl acetate solution, the ice-water bath controlled the temperature not to exceed 40°C, after dripping...

Embodiment 3

[0038] (1) Preparation of (S)-2,4-dihydroxy-N,N,N-trimethylbutylamine base

[0039] Add 30g (0.186mol) (S)-carnitine to a four-necked flask equipped with a thermometer, stirring, and an external bath, and then add 300ml of tetrahydrofuran. 0.465mol) (2.5eq) sodium borohydride, after adding, return to room temperature for reaction, after the reaction, add 16.8g of water to quench the reaction, evaporate THF and water under reduced pressure, then add 300ml of ethyl acetate, stir, and filter with suction , The purity of the product in the filtrate: 74.5%, the filtrate is directly used for the next step of salt formation.

[0040] (2) Preparation of (S)-2,4-dihydroxy-N,N,N-trimethylbutylamine hydrochloride

[0041] Put the ethyl acetate solution of (S)-2,4-dihydroxy-N,N,N-trimethylbutylamine base prepared above in a four-necked flask, and slowly add hydrogen chloride (0.205mol ) (1.1eq) of ethyl acetate solution, the temperature in an ice-water bath should not exceed 40°C, afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com