New crystal form of topirastat and preparation method thereof

A technology of topirax and crystal form, applied in the chemical and pharmaceutical field, to achieve the effect of high product purity, single crystal form, and short operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

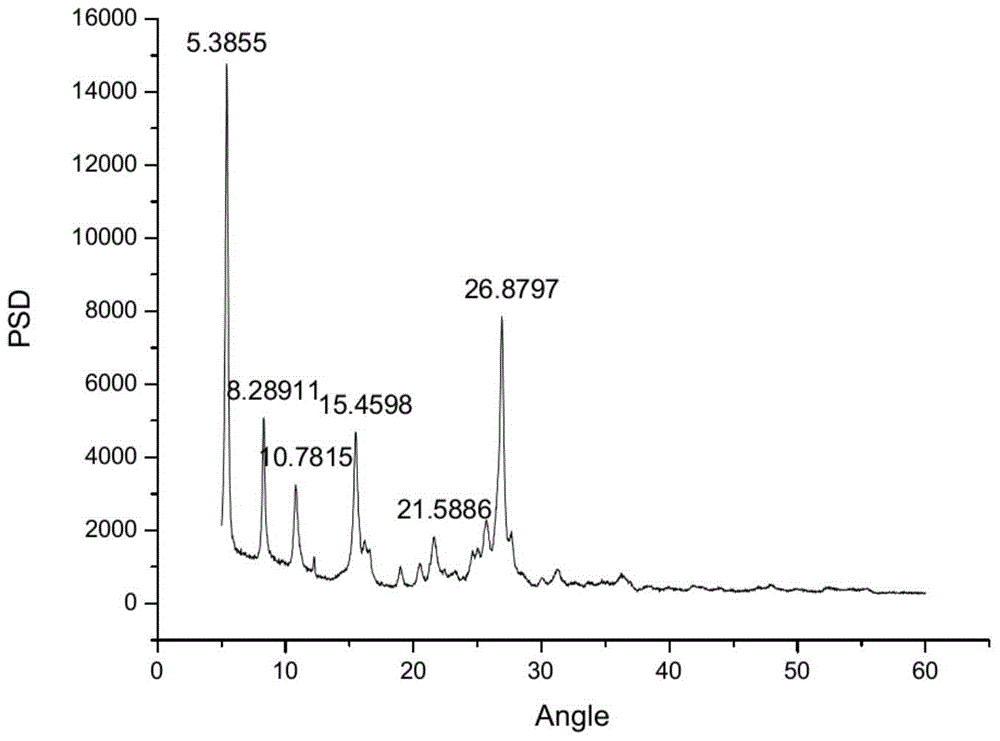

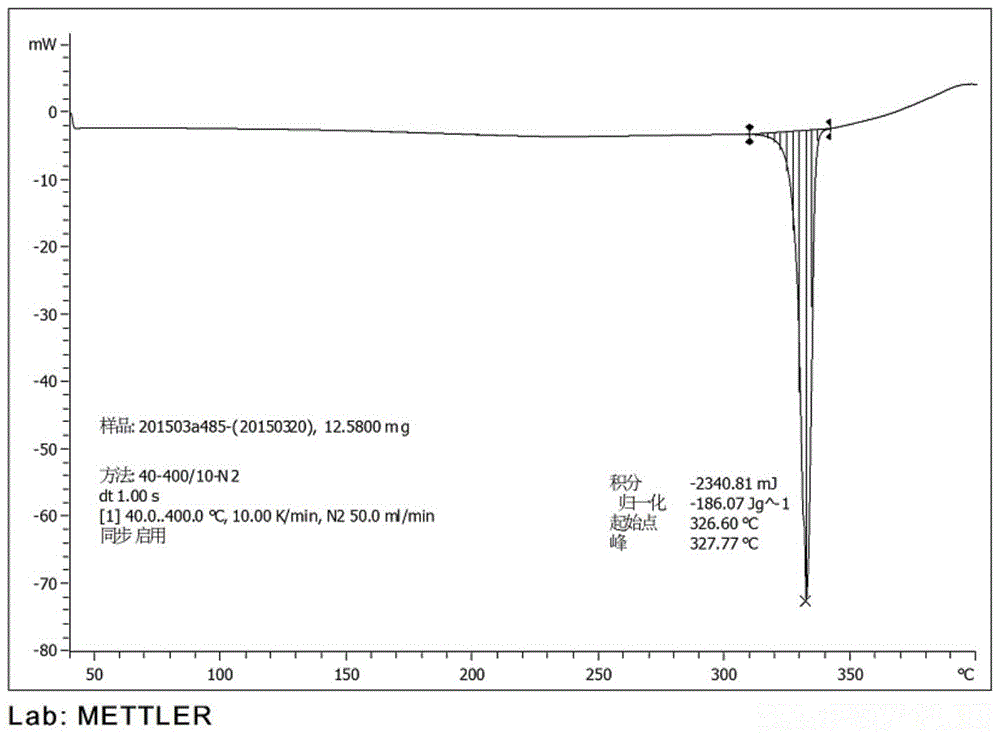

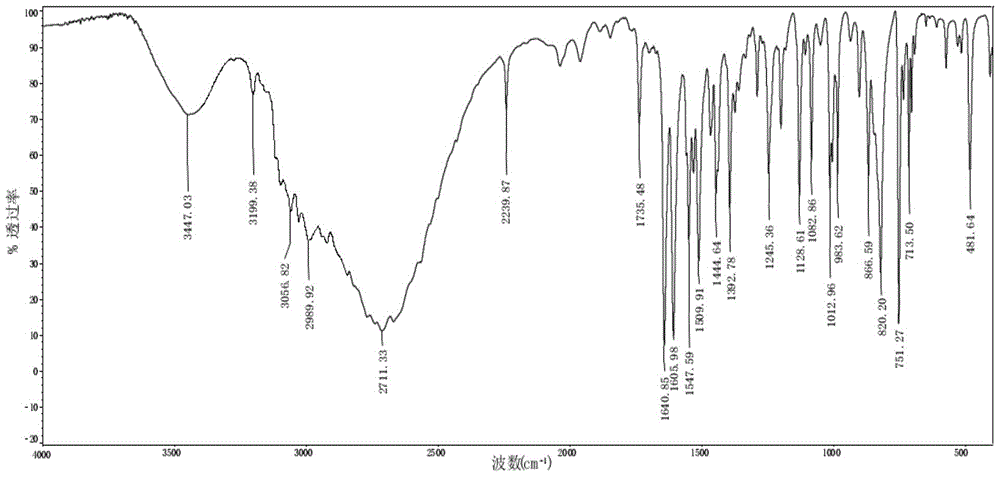

[0027] Add 500ml of dichloromethane, 100ml of methanol, 30.0g of topirastat to a clean and dry 1000ml reaction flask, add 18.4g of triethylamine, stir until the solid dissolves, add 0.6g of activated carbon, decolorize for 1 hour, filter out the activated carbon, Transfer the filtrate to another 1000ml reaction bottle, add 6N hydrochloric acid dropwise, adjust the pH to 6~7, after the dropwise addition, stir for 30min, filter with suction, rinse the filter cake with 30ml of a mixture of dichloromethane and methanol, and drain it , and the solid was air-dried at 30° C. for 6 hours to obtain a white solid, 28.5 g, which was topirastat crystal form III, with a yield of 95.0% and a purity of 99.8% by HPLC. The X-powder diffraction pattern of the topirastat crystal form III prepared in Example 1 is shown in figure 1 , whose DSC spectrum is shown in figure 2 , whose infrared spectrum is shown in image 3 .

Embodiment 2

[0029] Add 250ml of dichloromethane, 50ml of methanol, 30.0g of topirastat to a clean and dry 500ml reaction flask, add 36.8g of triethylamine, stir until the solid dissolves, add 0.6g of activated carbon, decolorize for 1 hour, filter out the activated carbon, Transfer the filtrate to another 500ml reaction bottle, add 6N hydrochloric acid dropwise, adjust the pH to 6~7, after the dropwise addition, stir for 30min, filter with suction, rinse the filter cake with 30ml of a mixture of dichloromethane and methanol, and drain it , and the solid was air-dried at 30° C. for 6 hours to obtain a white solid, 29.1 g, with a yield of 97.0% and a purity of 99.7% by HPLC.

Embodiment 3

[0031] Add 750ml of dichloromethane, 150ml of methanol, 30.0g of topirastat to a clean and dry 2000ml reaction flask, add 12.3g of triethylamine, stir until the solid dissolves, add 0.6g of activated carbon, decolorize for 1 hour, filter out the activated carbon, Transfer the filtrate to another 2000ml reaction bottle, add 6N hydrochloric acid dropwise, adjust the pH to 6~7, after the dropwise addition, stir for 30min, filter with suction, rinse the filter cake with 30ml of a mixture of dichloromethane and methanol, and drain it , and the solid was air-dried at 30° C. for 6 hours to obtain a white solid, 27.9 g, with a yield of 93.0% and a purity of 99.9% by HPLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com