Method for directly immobilizing tannase in fermentation liquor

A technology of immobilizing enzymes and tannases, which is applied in the direction of immobilizing on or in inorganic carriers, can solve the problems of restricting the large-scale application of tannases, the high cost of tannases, and the high cost of tannases. Achieve good reusability and magnetic manipulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

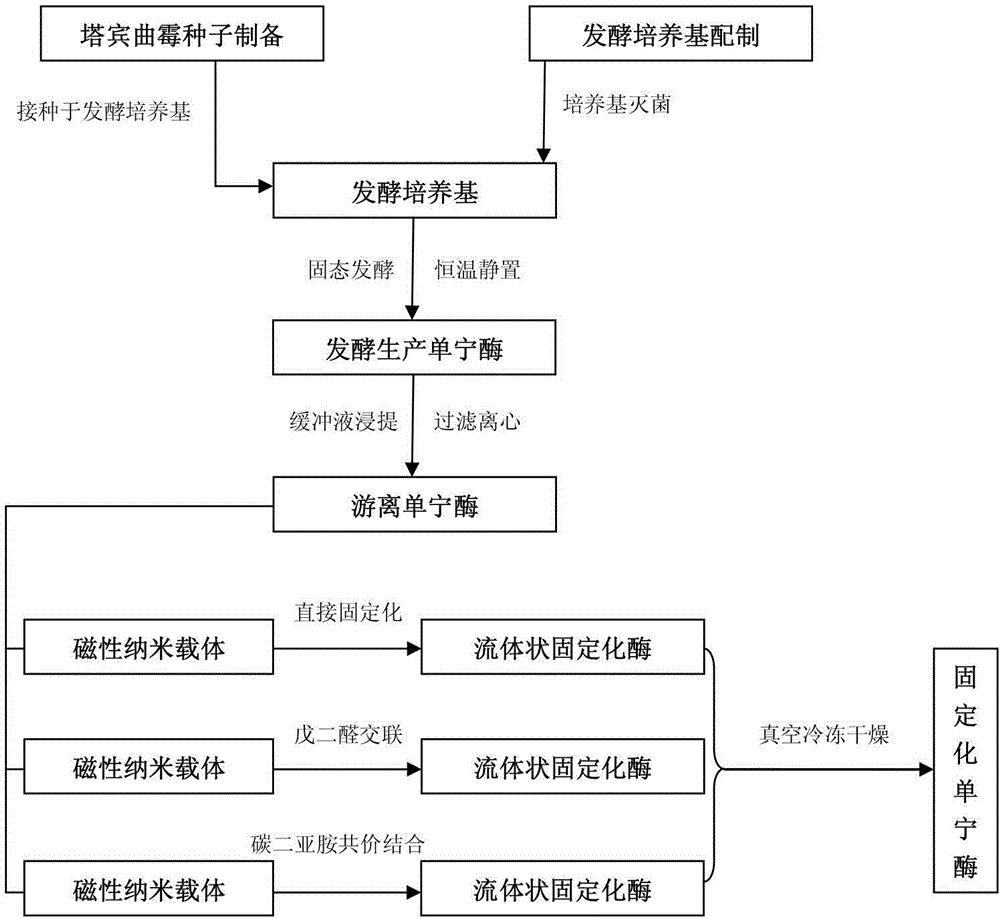

Method used

Image

Examples

Embodiment 1

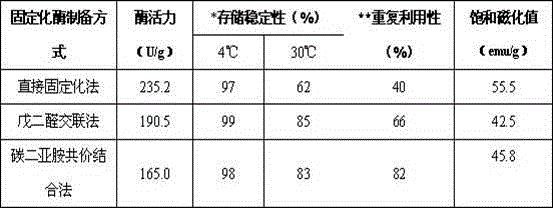

[0027] Example 1: Preparation of immobilized tannase by direct immobilization of magnetic nanoparticles

[0028] (1) Will Aspergillus tubingensis CICC 2651 slant strains were transferred to PDA slant and activated for 96 h, and the slant spores were washed with 0.8% sterile Tween-80 solution to prepare the concentration of 1.5×10 7 spore suspension per mL, inoculate 5 mL of spore suspension in a 250 mL shake flask (the medium is PD, that is, PDA-removed agar, the filling volume is 100 mL, and 5 glass beads with a diameter of 0.5 cm are added to each bottle) 28 Cultivate for 72 h at ℃ to obtain the fermented seed liquid of Aspergillus tubingensis.

[0029] (2) Take the dried Tieguanyin tea stalk powder and pass it through a 40-mesh sieve, add 9% sucrose, 3% glucose, 6% ammonium sulfate and 0.5% yeast extract, and the solid-water ratio is 1:2 (m:v) , sterilized at 121°C for 15 min and cooled to room temperature to obtain the fermentation medium. Each gram of fermentation me...

Embodiment 2

[0033] Example 2: Preparation of immobilized tannase by glutaraldehyde cross-linking method of magnetic nanoparticles

[0034] (1) Will Aspergillus tubingensis CICC 2651 slant strains were transferred to PDA slant and activated for 96 h, and the slant spores were washed with 0.8% sterile Tween-80 solution to prepare the concentration of 1.5×10 7 spore suspension per mL, inoculate 5 mL of spore suspension in a 250 mL shake flask (the medium is PD, that is, PDA-removed agar, the filling volume is 100 mL, and 5 glass beads with a diameter of 0.5 cm are added to each bottle) 28 Cultivate for 72 h at ℃ to obtain the fermented seed liquid of Aspergillus tubingensis.

[0035] (2) Take the dried Tieguanyin tea stalk powder and pass it through a 40-mesh sieve, add 9% sucrose, 3% glucose, 6% ammonium sulfate and 0.5% yeast extract, and the solid-water ratio is 1:2 (m:v) , sterilized at 121°C for 15 min and cooled to room temperature to obtain the fermentation medium. Each gram of f...

Embodiment 3

[0039] Example 3: Preparation of immobilized tannase by covalent binding of magnetic nanoparticles carbodiimide

[0040] (1) Will Aspergillus tubingensis CICC 2651 slant strains were transferred to PDA slant and activated for 96 h, and the slant spores were washed with 0.8% sterile Tween-80 solution to prepare the concentration of 1.5×10 7 spore suspension per mL, inoculate 5 mL of spore suspension in a 250 mL shake flask (the medium is PD, that is, PDA-removed agar, the filling volume is 100 mL, and 5 glass beads with a diameter of 0.5 cm are added to each bottle) 28 Cultivate for 72 h at ℃ to obtain the fermented seed liquid of Aspergillus tubingensis.

[0041] (2) Take the dried Tieguanyin tea stalk powder and pass it through a 40-mesh sieve, add 9% sucrose, 3% glucose, 6% ammonium sulfate and 0.5% yeast extract, and the solid-water ratio is 1:2 (m:v) , sterilized at 121°C for 15 min and cooled to room temperature to obtain the fermentation medium. Each gram of ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com