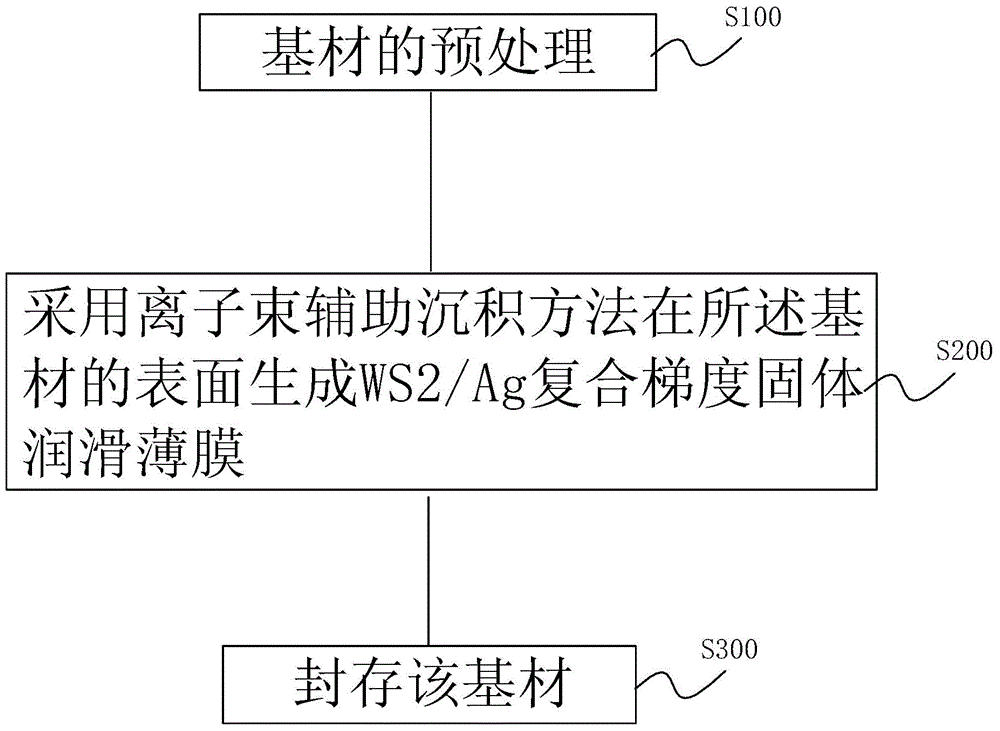

Method for preparing WS2/Ag compositional gradient solid lubrication film

A solid lubrication and manufacturing method technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of easy oxidation failure of the film, increase of friction coefficient, etc., achieve excellent wear resistance and improve film performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

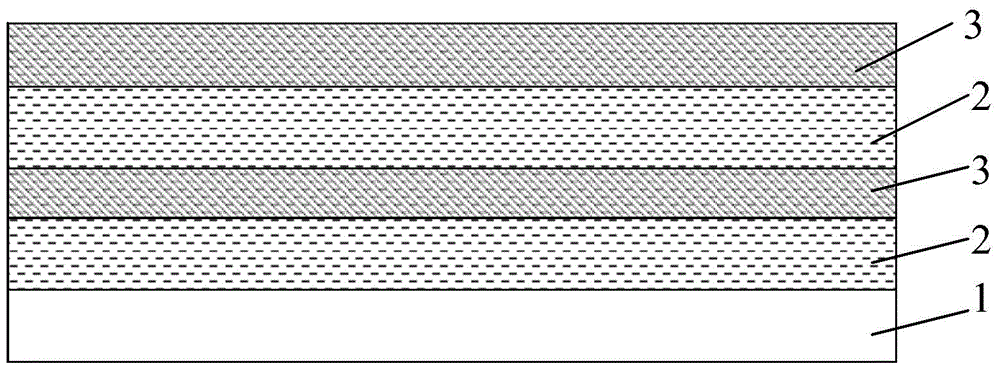

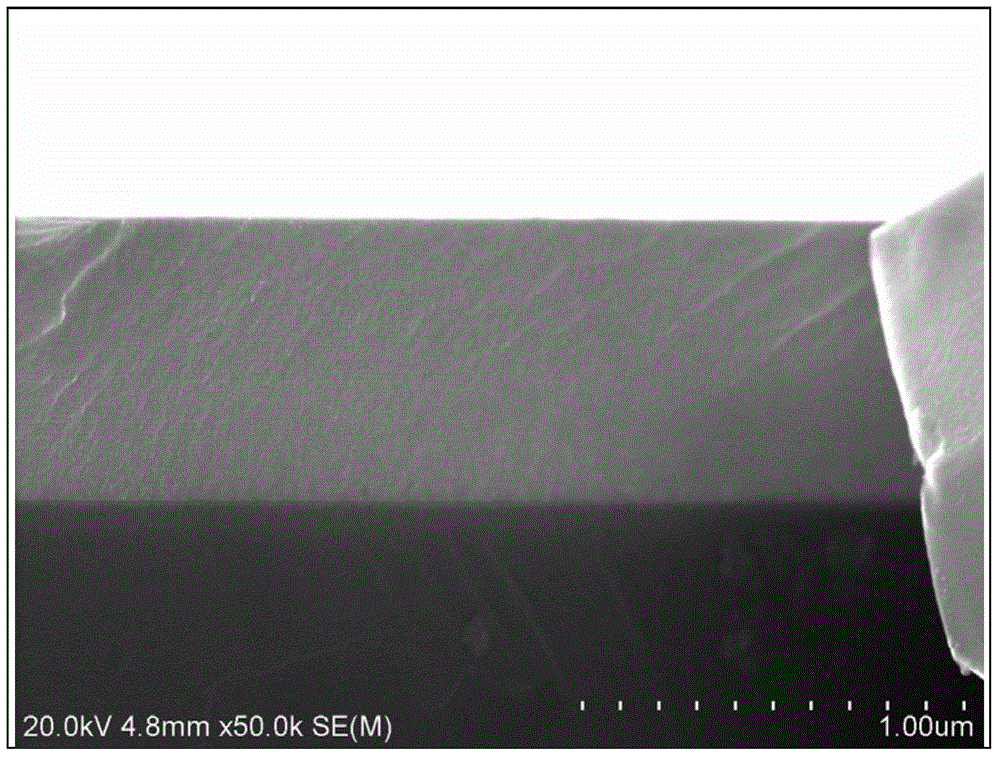

[0069] Put the substrate 1 on the sample stage of the vacuum chamber 10, and evacuate the vacuum chamber 10 to a vacuum degree of 3.0×10 -4Pa~1.8×10 -3 Pa, filled with argon with a purity of 99.99%. After cleaning the surface of the substrate 1 with a low-energy ion source 20, WS was prepared by alternating ion bombardment and magnetron sputtering. 2 / Ag composite gradient solid lubricating film, first perform ion recoil implantation, then sputter deposition, and cycle 40 times in sequence.

[0070] Ion recoil implantation can use MEVVA metal ion source, and the ion source uses a silver target with a purity of 99.8%. During ion recoil injection, the residence time of the substrate in front of the target was 4min, and the ion source voltage was 45kV.

[0071] Unbalanced magnetron sputtering using WS 2 target. During sputtering deposition, the residence time of the substrate in front of the target is 90s, the sputtering voltage is 700V-900V, the sputtering current is 1A-2A,...

Embodiment 2

[0073] Put the substrate 1 on the sample stage of the vacuum chamber 10, and evacuate the vacuum chamber 10 to a vacuum degree of 3.0×10 -4 Pa~1.8×10 -3 Pa, filled with argon with a purity of 99.99%. After cleaning the surface of the substrate 1 with a low-energy ion source 20, WS is prepared by alternately performing ion recoil implantation and magnetron sputtering. 2 / Ag composite gradient solid lubricating film, the first ion recoil implantation, and then sputtering deposition, followed by 6 cycles.

[0074] The ion recoil implantation adopts MEVVA metal ion source 40, and the ion source adopts a silver target with a purity of 99.8%. During ion recoil injection, the residence time of the substrate in front of the target was 3 min, and the ion source voltage decreased sequentially. The Ag ion source voltage for the first ion recoil injection is 60-80kV, the second Ag ion source voltage is 50-60kV, the third Ag ion source voltage is 40-50kV, and the fourth Ag ion source vo...

Embodiment 3

[0077] Put the substrate 1 on the sample stage of the vacuum chamber 10, and evacuate the vacuum chamber 10 to a vacuum degree of 3.0×10 -4 Pa~1.8×10 -3 Pa, filled with argon with a purity of 99.99%. After cleaning the surface of the substrate 1 with a low-energy ion source 20, WS is prepared by alternately performing ion recoil implantation and magnetron sputtering. 2 / Ag composite gradient solid lubricating film, first perform ion recoil implantation, then sputter deposition, and cycle 5 times in sequence.

[0078] The ion recoil implantation adopts MEVVA metal ion source 40, and the ion source adopts a silver target with a purity of 99.8%. During ion recoil implantation, the ion source voltage is 55kV, the ion source current is 15mA, and the residence time of the substrate 1 in front of the target decreases successively. The first ion recoil injection time is 3-10 minutes, the second injection time is 3-8 minutes, the third injection time is 2-6 minutes, the fourth injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com