Environmental protection ashing treatment process of calendaring copper foil

A technology of ashing treatment and rolling copper foil, which is applied in the field of environmentally friendly ashing treatment process, which can solve the problems of inability to meet the requirements of FPC production, poor copper foil resistance to peeling, etching and corrosion resistance, human, social and environmental hazards, etc. problems, to achieve the effect of good high temperature oxidation resistance, good corrosion resistance and good performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

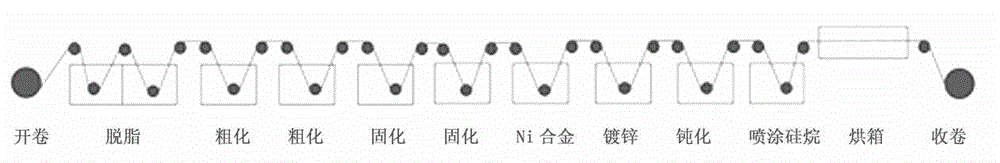

[0029] An environment-friendly ashing treatment process for rolled copper foil, which comprises the following steps:

[0030] 1) Degreasing and cleaning: Add a sodium hydroxide aqueous solution with a temperature of 50°C and a concentration of 50g / L into the degreasing tank to degrease and clean the copper foil;

[0031] 2) Roughening electroplating twice: add the roughening solution into the roughening PVC tank, and perform roughening electroplating on the copper foil obtained in step 1); the composition of the roughening solution: Cu 2+ : 10g / L; H 2 SO 4 : 100g / L; Temperature: 25°C;

[0032] 3) Curing and electroplating twice: Add the curing solution into the curing PVC tank, and perform curing and electroplating on the copper foil obtained in step 2); the composition of the curing solution: Cu 2+ : 40g / L; H 2 SO 4 : 100g / L; Temperature: 40°C;

[0033] 4) Nickel alloy electroplating: Add the nickel alloy electroplating solution into the nickel alloy PVC tank, and perfo...

Embodiment 2

[0038] An environment-friendly ashing treatment process for rolled copper foil, which comprises the following steps:

[0039] 1) Degreasing and cleaning: Add a sodium hydroxide aqueous solution with a temperature of 60°C and a concentration of 60g / L into the degreasing tank to degrease and clean the copper foil;

[0040] 2) Roughening electroplating twice: add the roughening solution into the roughening PVC tank, and perform roughening electroplating on the copper foil obtained in step 1); the composition of the roughening solution: Cu 2+ : 20g / L; H 2 SO 4 : 150g / L; Temperature: 30°C;

[0041] 3) Curing and electroplating twice: Add the curing solution into the curing PVC tank, and perform curing and electroplating on the copper foil obtained in step 2); the composition of the curing solution: Cu 2+ : 60g / L; H 2 SO 4 : 150g / L; Temperature: 50°C;

[0042] 4) Nickel alloy electroplating: Add the nickel alloy electroplating solution into the nickel alloy PVC tank, and perfo...

Embodiment 3

[0047] An environment-friendly ashing treatment process for rolled copper foil, which comprises the following steps:

[0048] 1) Degreasing and cleaning: Add an aqueous sodium hydroxide solution with a temperature of 70°C and a concentration of 80g / L into the degreasing tank to degrease and clean the copper foil;

[0049] 2) Roughening electroplating twice: add the roughening solution into the roughening PVC tank, and perform roughening electroplating on the copper foil obtained in step 1); the composition of the roughening solution: Cu 2+ : 30g / L; H 2 SO 4 : 200g / L; Temperature: 45°C;

[0050] 3) Curing and electroplating twice: Add the curing solution into the curing PVC tank, and perform curing and electroplating on the copper foil obtained in step 2); the composition of the curing solution: Cu 2+ : 80g / L; H 2 SO 4 : 200g / L; Temperature: 55°C;

[0051] 4) Nickel alloy electroplating: Add the nickel alloy electroplating solution into the nickel alloy PVC tank, and perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com