Manufacturing method of crystalline silicon solar cell

A technology of solar cells and manufacturing methods, applied in the field of solar cells, capable of solving problems such as high series resistance and low open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

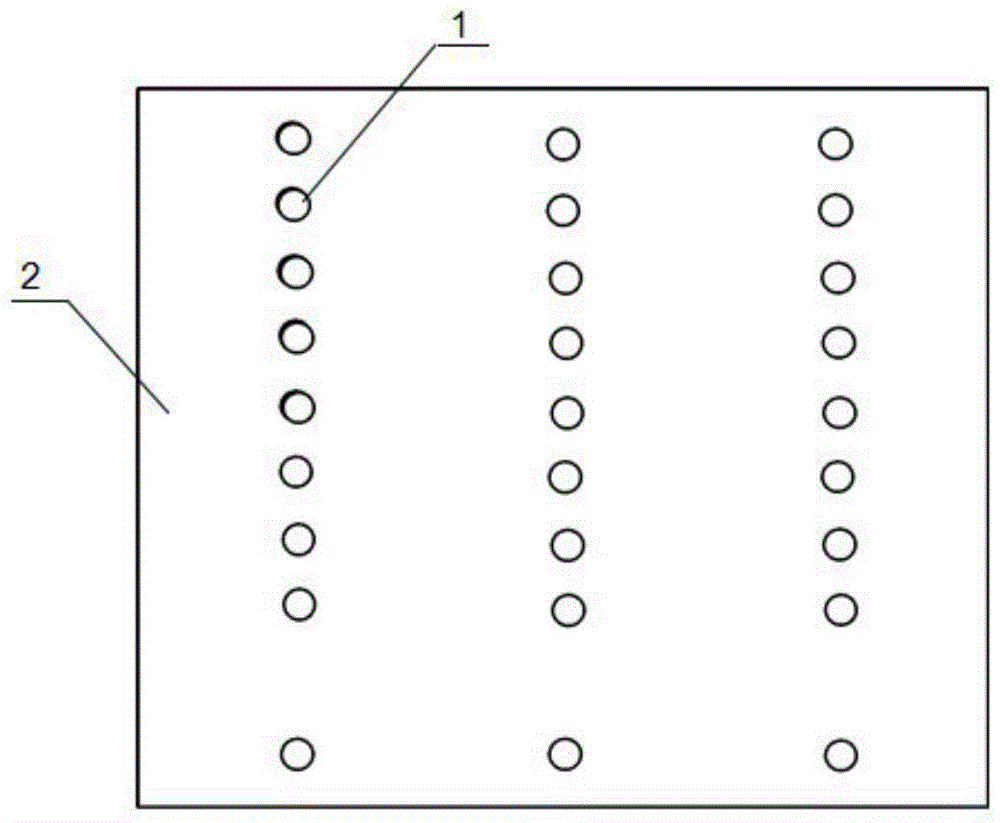

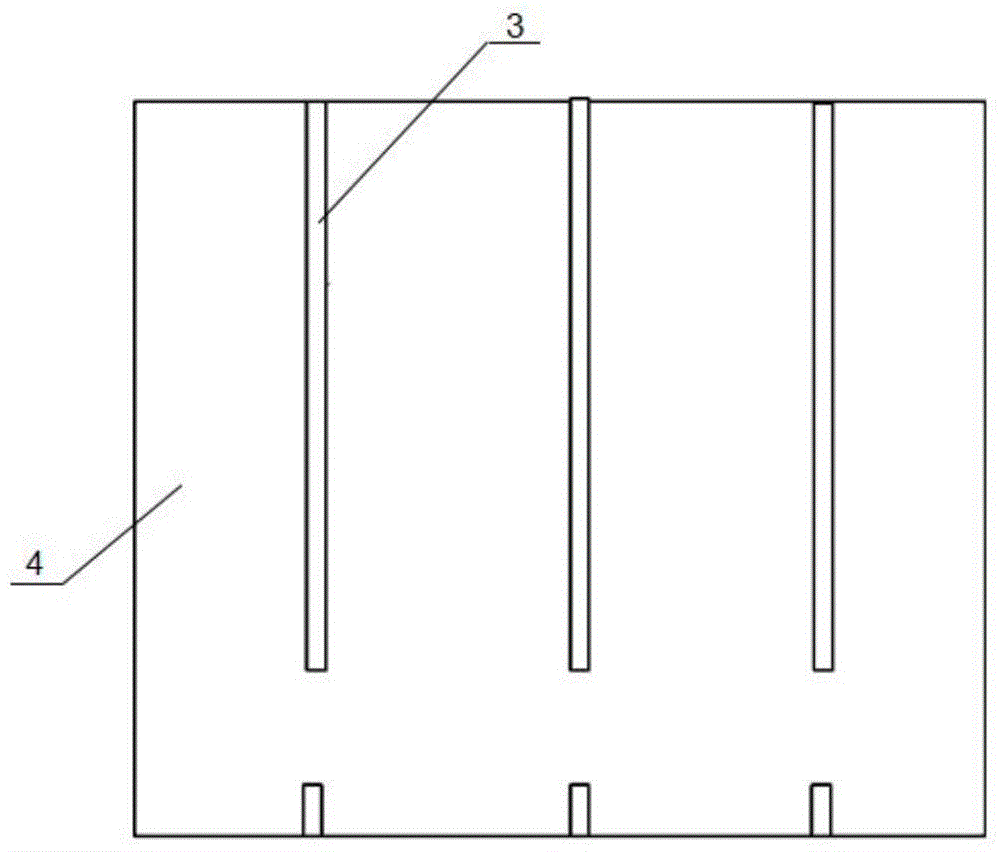

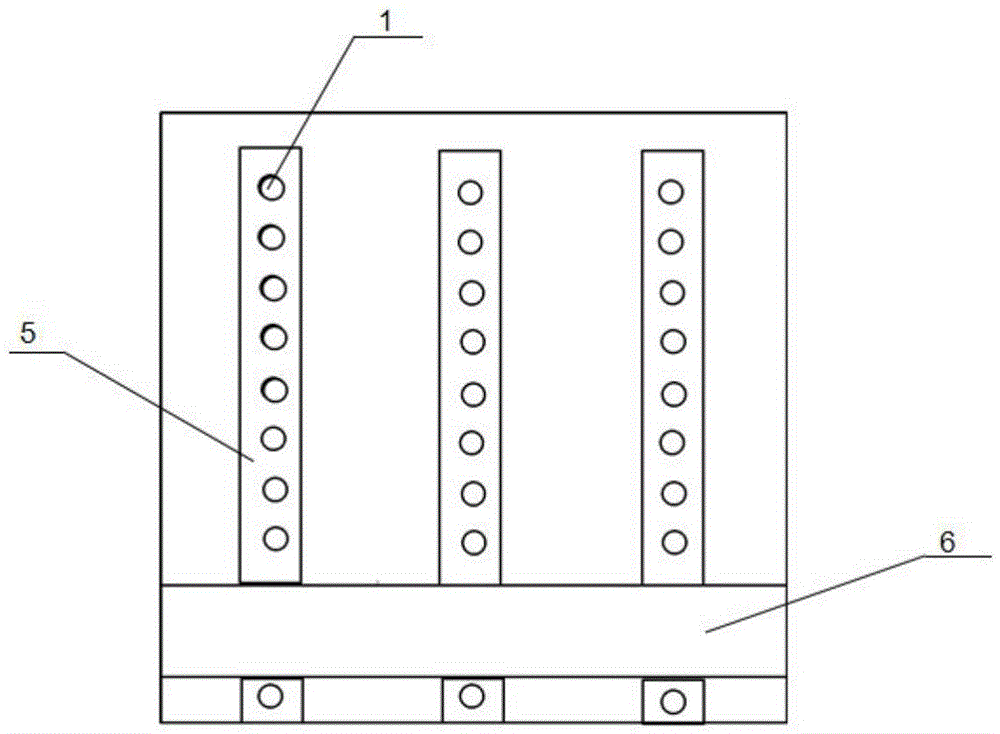

Image

Examples

Embodiment 1

[0047] The manufacturing method of n-type double-sided solar cells: Take an n-type single crystal silicon, use 15-30% alkali solution to perform corrosion cleaning on the single crystal silicon at 80-100°C for 0.5-1min, to remove oil stains, cut Damaged layer, etc., the cleaned single crystal silicon is formed on the surface of the silicon wafer by mechanical grooving, chemical etching, reactive ion etching, laser grooving and other methods to reduce surface reflection loss, and then use diffusion The p-diffusion layer is formed on the front side of the silicon wafer to form a PN junction; then, the n-diffusion layer is formed on the back side by a diffusion method to form an n + Floor. For example, by using atmospheric pressure chemical vapor deposition (APCVD), borosilicate glass (BSG) is deposited at 500-800°C for boron diffusion and deposition of SiO 2 membrane, then with POCl 3 Phosphorus diffusion is carried out by liquid source diffusion method, that is, through a cer...

Embodiment 2

[0054] Passivated Emitter Rear Contact (PERC) silicon solar cells increase the conversion efficiency of the cell by adding a qualitative passivation layer on the back of the cell. This technique prepares SiO on the back surface of conventional cells. 2 、Al 2 o 3 , SiOx or Al 2 o 3 / SiN x The passivation film maximizes the potential difference between the p-n junctions and reduces the recombination of electrons, thereby improving battery efficiency. PECR batteries require laser etching on the back passivation layer, and then make the aluminum paste locally form a back electric field battery (BSF ) and electrical contacts, thereby increasing Voc and Isc. In this method, the front side of the battery is also partially etched at the same time, and a local electric contact is formed on the etched silicon surface with a non-burn-through silver paste. The sintering temperature of the battery can be greatly reduced by using the non-fire-through paste, and the sintering peak tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com