Preparation method of SiBCN ceramic precursor containing borazine structure

A technology of ceramic precursor and borazane, which is applied in the field of preparation of SiBCN ceramic precursor, can solve the problems of difficult process control, difficulty in mass preparation, and difficulty in wide application of SiBCN ceramic matrix composite materials, and achieves low cost of raw materials , Excellent thermal stability, and the effect of large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) In an anhydrous and oxygen-free environment, put the pre-activated magnesium chips into a Schlenk reaction flask. Under the protection of nitrogen, add 15mL tetrahydrofuran and 1.3g chloromethylmethylsilane. When the tetrahydrofuran is refluxed, place it in an ice bath. Add dropwise a mixed solution of 20.5g of chloromethylmethylsilane and 30mL of tetrahydrofuran, and then reflux at 60°C for 8 hours to obtain a Grignard reagent;

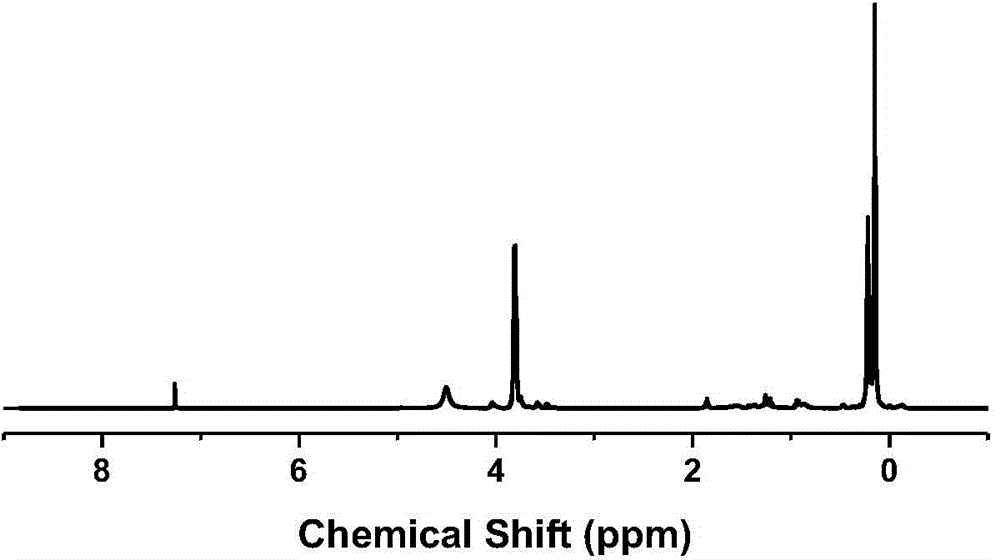

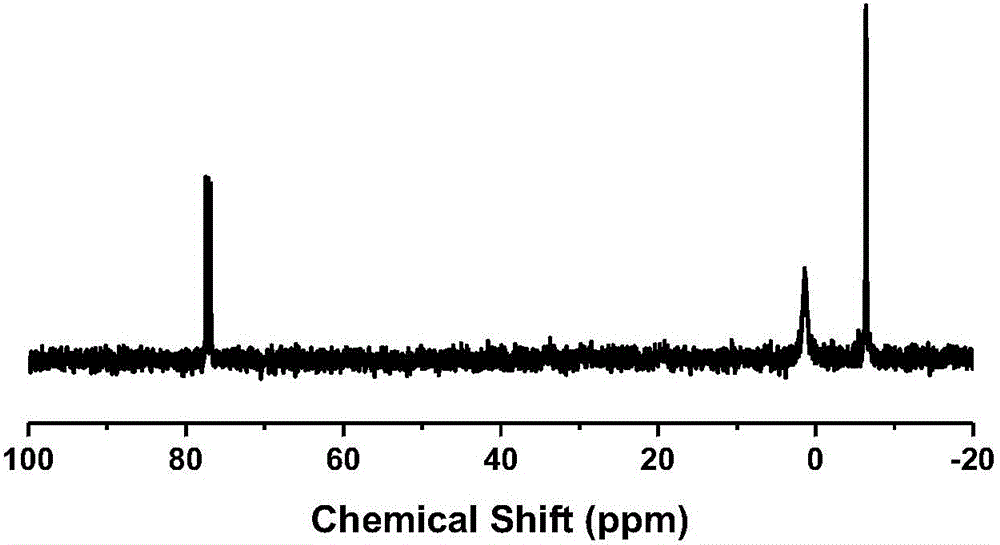

[0034] 2) In an anhydrous and oxygen-free environment, add dropwise a mixed solution of 12.9 g of trichloroborazine and 50 mL of toluene to the Grignard reagent obtained in step 1) under an ice bath, and then stir at room temperature for 8 hours, Remove the solvent and by-products to obtain the small molecule product containing the borazine structure; use a nuclear magnetic analyzer to characterize its H spectrum and C spectrum, such as figure 1 with 2 Shown.

Embodiment 2

[0036] 1) In an anhydrous and oxygen-free environment, put the pre-activated magnesium chips into a Schlenk reaction flask. Under the protection of nitrogen, add 15 mL of ether and 1.5 g of chloromethyl methyl dichlorosilane. When the ether is refluxed, Add dropwise a mixed solution of 30.5g chloromethylmethyldichlorosilane and 50mL ether under an ice bath, and then reflux at 80°C for 6 hours to obtain a Grignard reagent;

[0037] 2) In an anhydrous and oxygen-free environment, add dropwise a mixed solution of 14.9 g of dichloroborazine and 50 mL of toluene to the Grignard reagent obtained in step 1) under an ice bath, and then stir at room temperature for 8 hours, Remove the solvent and by-products to obtain small molecular products containing borazine structure;

[0038] 3) In an anhydrous and oxygen-free environment, pass ammonia gas into the small molecule product in step 2) at -30°C until the system shows basicity. At this time, the amount of ammonia gas is about the Si-Cl gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com