Carbon/carbon composite material binder, bonding method and carbon/carbon composite material component

A carbon composite material and binder technology, which is applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesives, adhesive types, etc. and other problems, to achieve the effect of good resistance to strong acid, convenient preparation and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Weigh 10 grams of phenolic resin (solid content 60%, viscosity 0.5 Pa s), 1 gram of chopped carbon fiber powder (length 100 ± 50 μm) and mix well to obtain a corrosion-resistant high-strength adhesive;

[0034] (2) Using carbon / carbon composite material as the bonding material, adopt absolute ethanol and acetone to clean and dry the bonding material;

[0035] (3) After brushing uniform adhesive on the joint surface of the bonding material, let it stand for 2 hours and then bond, and the bonding pressure is 1MPa;

[0036] (4) The bonded carbon / carbon composite material sample cured at room temperature was raised to 180°C for 2 hours at a heating rate of 1°C / min;

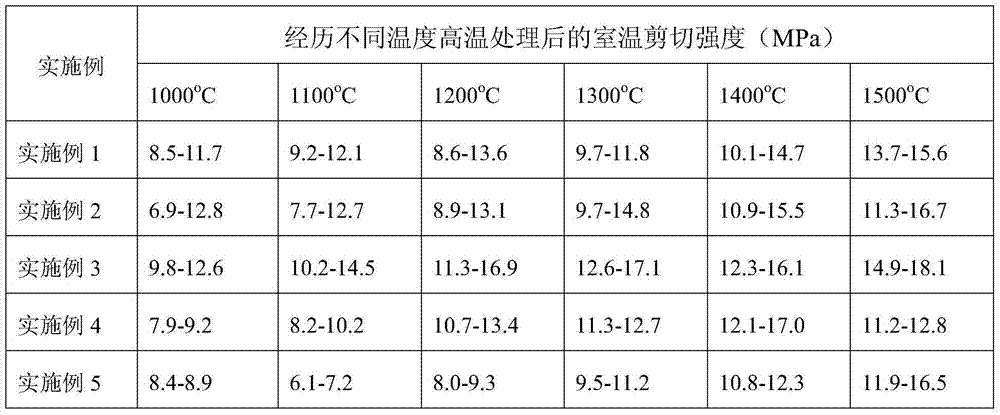

[0037] (5) Place the cured bonded carbon / carbon composite material in a heat treatment furnace, and raise the temperature to 1000°C, 1100°C, 1200°C, 1300°C, 1400°C, Heat treatment at 1500°C for 2 hours at high temperature. After taking it out, test the bond shear strength at different heat treatment temperat...

Embodiment 2

[0039] (1) Weigh 10 grams of phenolic resin (solid content 65%, viscosity 1.0 Pa s), 2 grams of chopped carbon fiber powder (length 200 ± 50 μm) and mix well to obtain a corrosion-resistant high-strength adhesive;

[0040] (2) Using carbon / carbon composite material as the bonding material, use absolute ethanol and acetone to clean and dry the bonding material

[0041] (3) After brushing uniform adhesive on the joint surface of the adhesive material, let it stand for 4 hours before bonding, and the bonding pressure is 2MPa;

[0042] (4) The bonded carbon / carbon composite material sample cured at room temperature was raised to 180°C for 2 hours at a heating rate of 3°C / min;

[0043] (5) Put the cured bonded carbon / carbon composite material in a heat treatment furnace, and raise the temperature to 1000°C, 1100°C, 1200°C, 1300°C, 1400°C, Heat treatment at 1500°C for 2 hours at high temperature. After taking it out, test the bond shear strength at different heat treatment temperat...

Embodiment 3

[0045] (1) Weigh 10 grams of phenolic resin (solid content 70%, viscosity 1.5 Pa s), 3 grams of chopped carbon fiber powder (length 300 ± 50 μm) and mix well to obtain a corrosion-resistant high-strength adhesive;

[0046] (2) Using carbon / carbon composite material as the bonding material, use absolute ethanol and acetone to clean and dry the bonding material

[0047] (3) After applying a uniform adhesive on the joint surface of the adhesive material, let it stand for 6 hours before bonding, and the bonding pressure is 3MPa;

[0048] (4) The bonded carbon / carbon composite material sample cured at room temperature was raised to 180°C for 2 hours at a heating rate of 5°C / min;

[0049] (5) Put the cured bonded carbon / carbon composite material in a heat treatment furnace, and raise the temperature to 1000°C, 1100°C, 1200°C, 1300°C, 1400°C, Heat treatment at 1500°C for 2 hours at high temperature. After taking it out, test the bond shear strength at different heat treatment temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com