Protective films, film laminates and polarizers

A protective film, general-type technology, applied in optics, optical components, polarizing components, etc., can solve the problem that the polarizing film cannot function as a polarizing plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0251] "Protective film and film laminate preparation method"

[0252] [Protection film formation process]

[0253] As long as the above-mentioned protective film can be prepared, the method for preparing the protective film of the present invention is not particularly limited, but as an example, a method including a protective film forming step including the following steps (A1) and (A2) can be cited.

[0254] Step (A1): Apply the energy beam curable composition on the film substrate or the release layer of the film substrate.

[0255] Step (A2): After coating, the energy beam curable composition is cured to form a protective film.

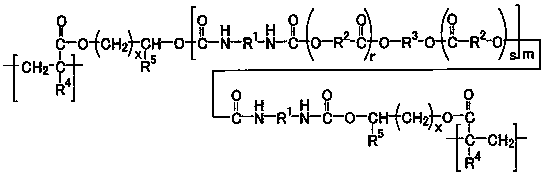

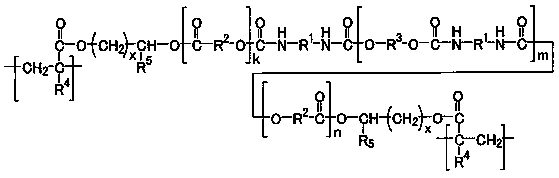

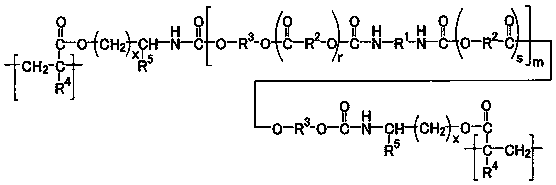

[0256] The energy beam curable composition contains urethane (meth)acrylate as an essential component. The above-mentioned urethane (meth)acrylate as a monomer is a raw material of the protective film, and the repeating unit described in the above-mentioned "Protective Film" is formed by polymerizing this monomer.

[0257] In another embodiment, as a raw m...

Embodiment

[0339] Hereinafter, the present invention will be described based on Examples and Comparative Examples, but the present invention is not limited to the content of the Examples. The protective film obtained by peeling the polyester film substrate from the obtained film laminate (the protective film and the functional layer when the functional layer is formed on the film substrate) was used as the measurement object, and the protection was measured by the following measurement method The moisture permeability and tensile strength of the film.

[0340] [Film thickness]

[0341] Using a digital linear meter D-10HS and a digital counter C-7HS (manufactured by Ozaki Manufacturing Co., Ltd.), the film thickness of the protective film (or protective film + functional layer) was measured.

[0342] [Water vapor permeability]

[0343] According to the moisture permeability test method (cup method) of JIS Z0208, the protective film is measured per 1m in an atmosphere with a temperature of 40°C a...

preparation example 1

[0349] Synthesis of compound 1:

[0350] 196.29 g (1 mol) of tricyclodecane dimethanol and 228.29 g (2 mol) of ε-caprolactone were put into the flask, the temperature was raised to 120°C, and 50 ppm of monobutyl tin oxide was added as a catalyst. Then, under a nitrogen stream, the reaction was performed until the remaining ε-caprolactone was 1% or less in the gas chromatography to obtain the diol (1).

[0351] Put 444.58g (2 moles) of isophorone diisocyanate in another flask, add 425.57g (1 mole) of diols at a reaction temperature of 70°C, and the time when the remaining isocyanate groups become 5.7% Add 232.24g (2 moles) of 2-hydroxyethyl acrylate and 0.35g of dibutyltin laurate, and react until the residual isocyanate group becomes 0.1%, and the monomer that forms the repeating unit (block A) is obtained. Urethane acrylate (compound 1) (m of the repeating unit of compound 1 in the general formula (1a) is 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com