Fuel-cell gas dispersion layer, and method for producing same

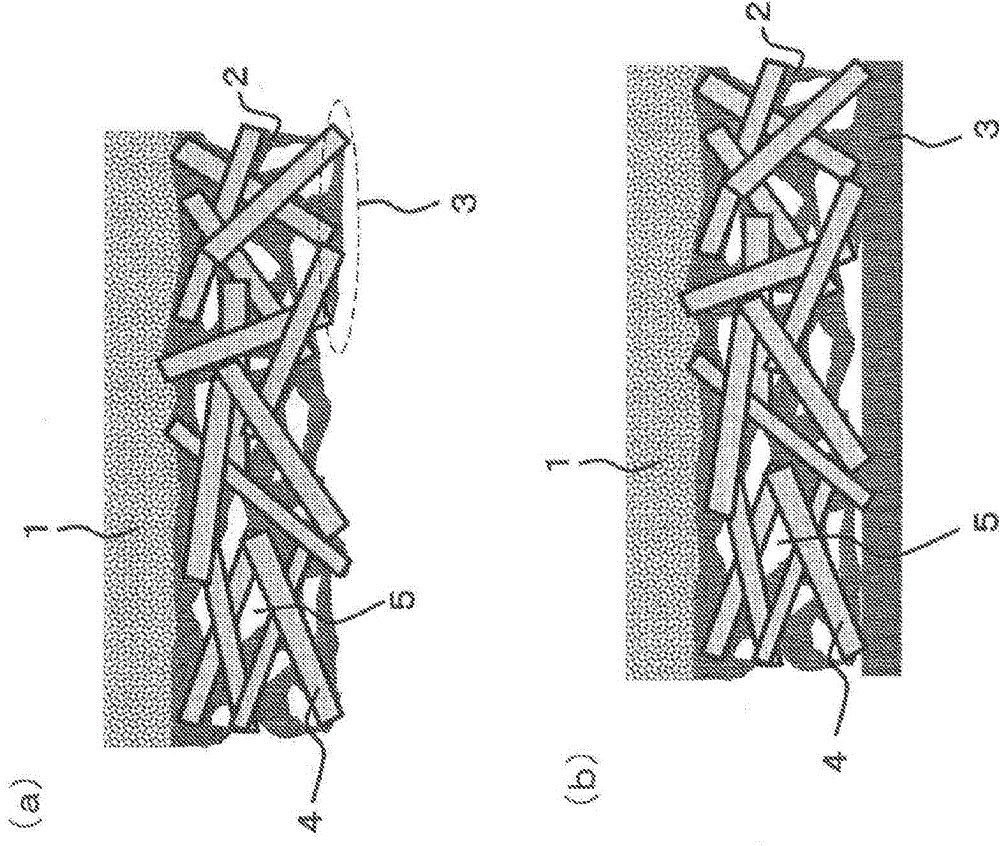

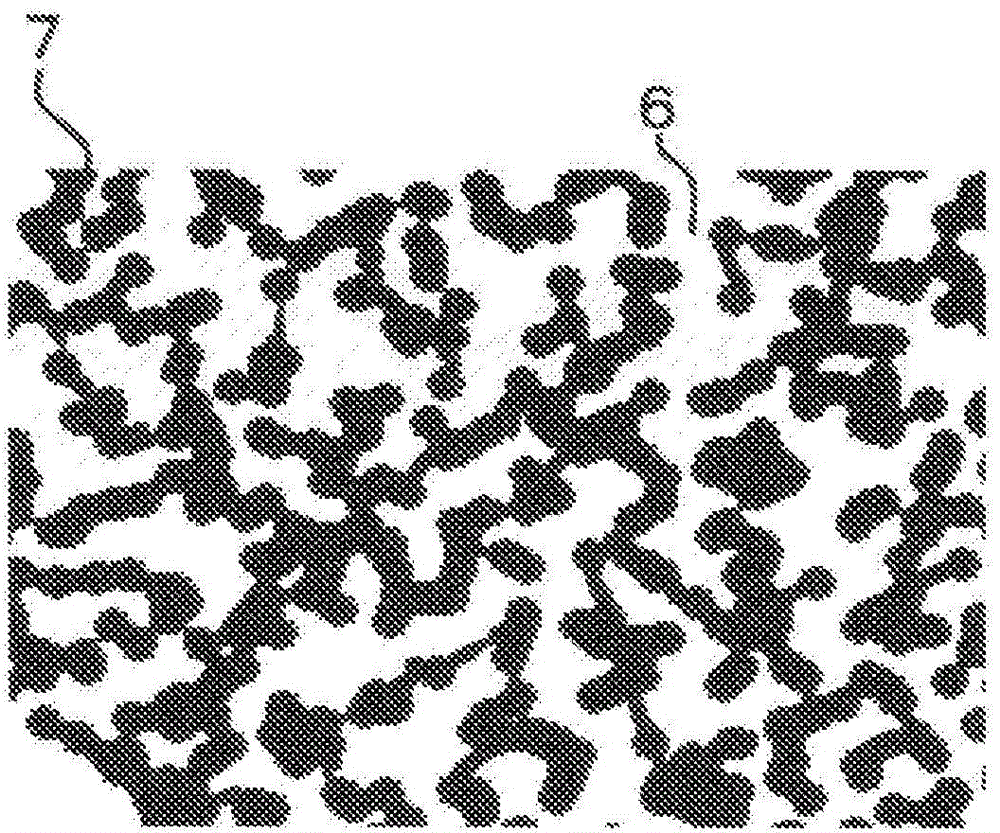

A gas diffusion layer and fuel cell technology, applied in fuel cells, solid electrolyte fuel cells, electrical components, etc., can solve problems such as the durability of porous layers, achieve high power generation performance, excellent smoothness, and suppress short-circuit effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

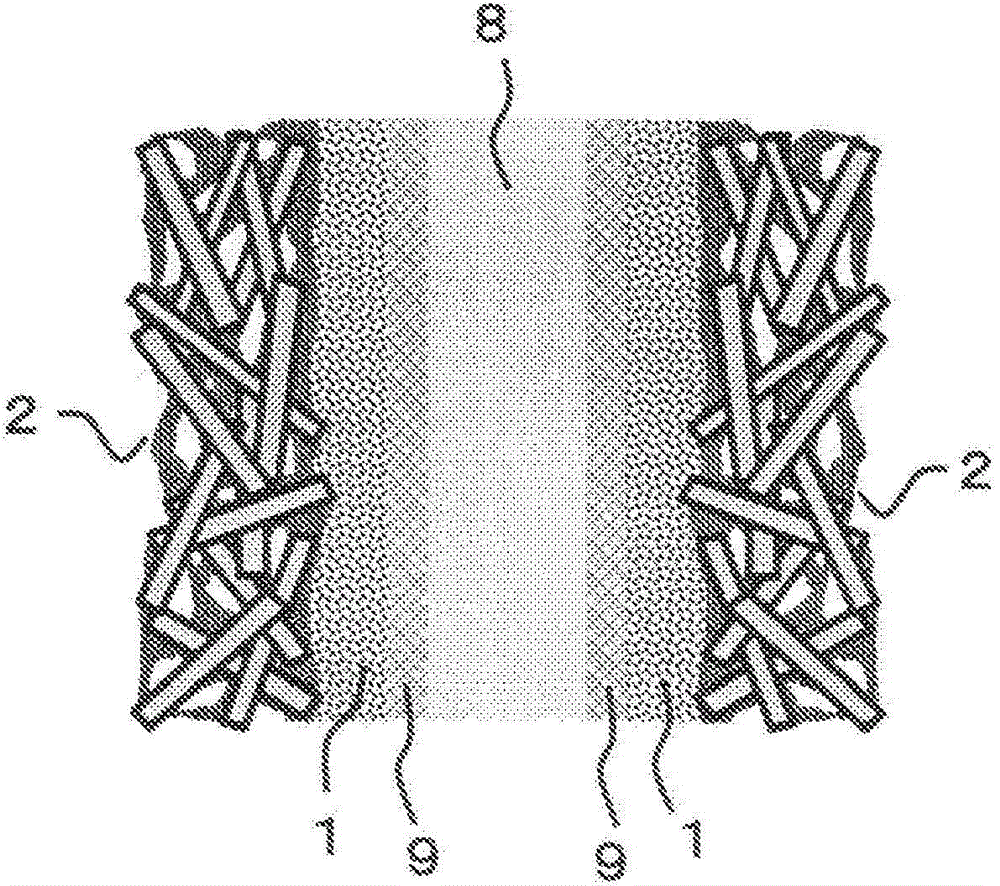

Embodiment 1

[0182] Toray Co., Ltd.'s polypropylene eye-based carbon fiber "Tureka" (registered trademark) T300 (average single fiber diameter: 7μm) is cut into a length of 12mm, and it is continuously sheeted using water as a sheeting medium, and then dipped in polyvinyl alcohol. 10% by mass aqueous solution and drying papermaking process, the mass per unit area of carbon fiber is 16g / m 2 Long strips of carbon fiber paper. The amount of polyvinyl alcohol added corresponds to 20 parts by mass relative to 100 parts by mass of carbon fibers.

[0183] A dispersion liquid in which flaky graphite (average particle diameter: 5 μm), phenol resin, and methanol were mixed in a mass ratio of 1:9:50 was prepared. After the above-mentioned dispersion liquid is continuously impregnated in the above-mentioned carbon fiber paper at a temperature of 90° C. to obtain a resin-impregnated carbon fiber paper (pre-preg body). As the phenolic resin, a resin obtained by mixing a resol type phenolic resin an...

Embodiment 2

[0198] Except in in Example 1, the average thickness t1 (μm) of the porous layer (A) after sintering is changed to 15μm, the mass per unit area of the porous layer (A) is 8g / m 2 Except for this, a gas diffusion layer was obtained in the same manner as in Example 1. As a result of evaluating the power generation performance of the gas diffusion layer, the blocking resistance was good. The output voltage is 0.37V (operating temperature is 65°C, humidification temperature is 70°C, current density is 2.2A / cm 2 ), the critical temperature is 90°C (the humidification temperature is 70°C, the current density is 1.2A / cm 2 ), as shown in Table 1, the overflow resistance and drying resistance were good. Cracks on the surface of the porous layer (A) were not confirmed.

Embodiment 3

[0200]Except in in Example 1, the average thickness t1 (μm) of the porous layer (A) after sintering is changed to 52μm, the mass per unit area of the porous layer (A) is 26 / m 2 Except for this, a gas diffusion layer was obtained in the same manner as in Example 1. As a result of evaluating the power generation performance of this gas diffusion layer, the anti-clogging property was extremely good. The output voltage is 0.36v (the operating temperature is 65°C, the humidification temperature is 70°C, and the current density is 2.2A / m 2 ), the critical temperature is 90°C (the humidification temperature is 70°C, and the current density is 1.2A / cm 2 ), as shown in Table 1, the overflow resistance and drying resistance were good. The number of cracks on the surface of the porous layer (A) was one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com