Chitosan derivative antibacterial superabsorbent gel and preparation method therefor

A technology of chitosan derivatives and superabsorbent, applied in the field of biomaterials and natural polymers, can solve the problems of insufficient antibacterial properties and limited applications, and achieve the effects of overcoming the insufficient antibacterial performance, low preparation cost, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

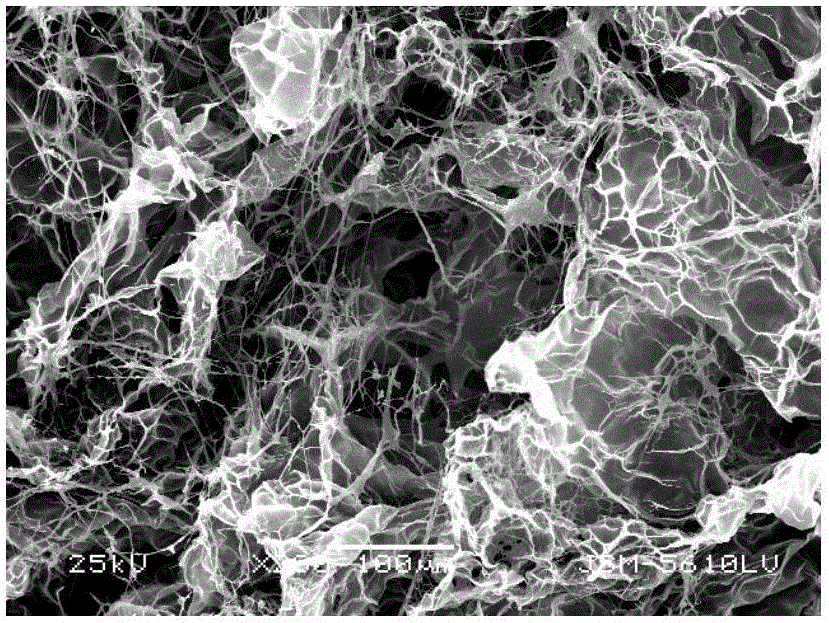

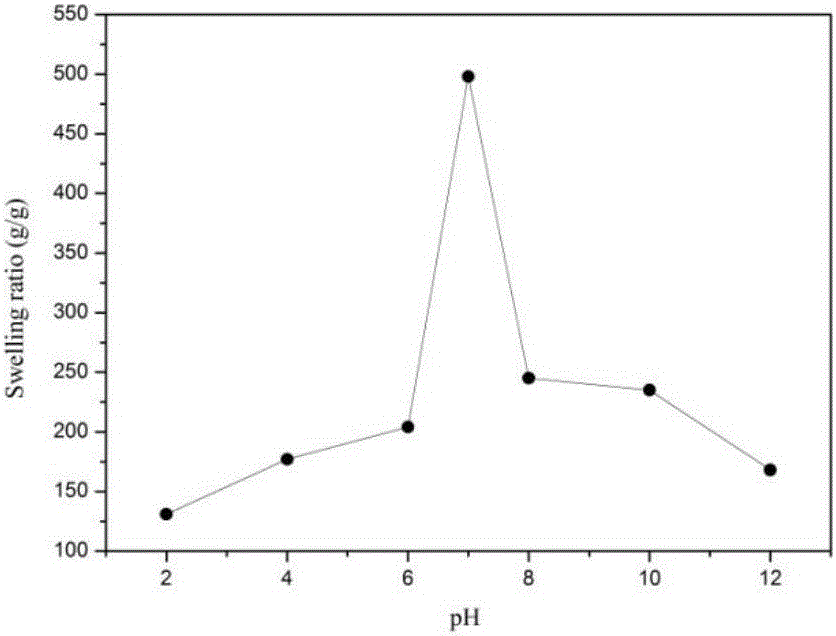

Image

Examples

Embodiment 1

[0025] A preparation method of chitosan derivative antibacterial superabsorbent gel, it comprises the steps:

[0026] 1) Selection of raw materials: according to the mass percentage of each raw material: chitosan quaternary ammonium salt 11%, acrylic acid 89%, potassium persulfate 1.8%, N, N-methylenebisacrylamide 0.36%, for later use;

[0027] 2) Weigh chitosan quaternary ammonium salt in a beaker according to the proportion, add 60ml of distilled water, stir to make it dissolve, and transfer it to a 250ml three-neck flask after dissolving evenly;

[0028] 3) Weigh a certain amount of acrylic acid (AA) in a 50ml round bottom bottle, add 15% NaOH solution dropwise while stirring under ice bath conditions, the neutralization degree is 80%, after the neutralization reaction is complete, the acrylic acid Sodium solution is transferred in the three-necked flask;

[0029] 4) Introduce nitrogen gas into the three-necked flask, and stir to mix the solution evenly; add the initiator ...

Embodiment 2

[0033] A preparation method of chitosan derivative antibacterial superabsorbent gel, it comprises the steps:

[0034] 1) Selection of raw materials: according to the mass percentage of each raw material: chitosan quaternary ammonium salt 12.5%, acrylic acid 87.5%, potassium persulfate 2.6%, N, N-methylenebisacrylamide 0.35%, for later use;

[0035] 2) Weigh chitosan quaternary ammonium salt in a beaker according to the proportion, add 60ml of distilled water, stir to make it dissolve, and transfer it to a 250ml three-neck flask after dissolving evenly;

[0036] 3) Weigh a certain amount of acrylic acid (AA) in a 50ml round bottom bottle, add 15% NaOH solution dropwise while stirring under ice bath conditions, the neutralization degree is 80%, after the neutralization reaction is complete, the acrylic acid Sodium solution is transferred in the three-necked flask;

[0037] 4) Introduce nitrogen gas into the three-necked flask, and stir to mix the solution evenly; add the initia...

Embodiment 3

[0041] A preparation method of chitosan derivative antibacterial superabsorbent gel, it comprises the steps:

[0042] 1) Selection of raw materials: according to the mass percentage of each raw material: 20% chitosan quaternary ammonium salt, 80% acrylic acid, 1.6% potassium persulfate, 0.32% N, N-methylenebisacrylamide, for future use;

[0043] 2) Weigh chitosan quaternary ammonium salt in a beaker according to the proportion, add 60ml of distilled water, stir to make it dissolve, and transfer it to a 250ml three-neck flask after dissolving evenly;

[0044] 3) Weigh a certain amount of acrylic acid (AA) in a 50ml round bottom bottle, add 15% NaOH solution dropwise while stirring under ice bath conditions, the neutralization degree is 80%, after the neutralization reaction is complete, the acrylic acid Sodium solution is transferred in the three-necked flask;

[0045] 4) Introduce nitrogen gas into the three-necked flask, and stir to mix the solution evenly; add the initiator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com