Method for preparing P-type low-defect silicon carbide epitaxial wafer

A silicon carbide and epitaxial wafer technology, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of long consumption time, limited effect of ultra-thick silicon carbide epitaxial wafers, and reduced quality of epitaxial layers, etc. The effect of period extension and reduction of basal plane dislocation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

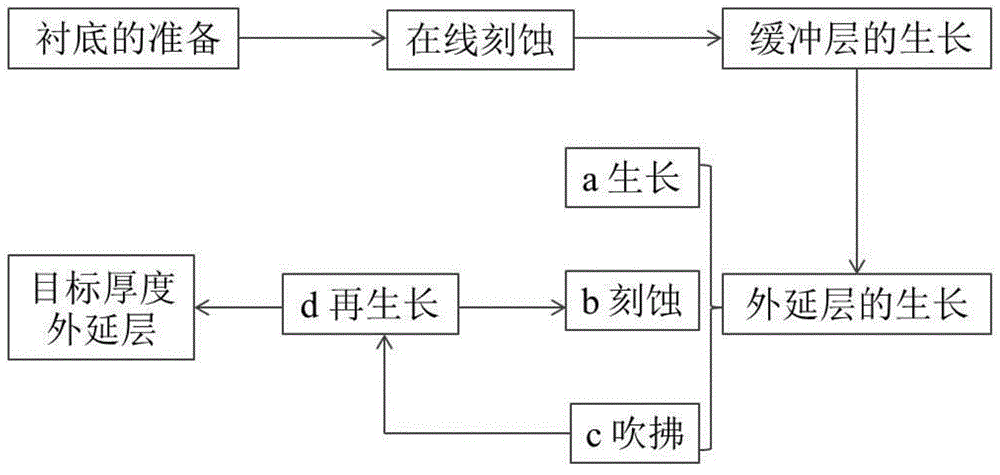

[0033] A method for preparing a P-type low-defect thickness 15um silicon carbide epitaxial wafer, comprising the following steps:

[0034] 1) Etching the substrate online: place a 4H-SiC substrate in the reaction chamber, vacuumize, and feed in hydrogen gas at a flow rate of 40L / min and HCl at a flow rate of 5L / min. The pressure in the reaction chamber is 40mbar and the temperature is 1680°C. minute;

[0035] 2) Growth of the buffer layer: Stop feeding HCl, lower the temperature to 1650°C, and feed SiH with a flow rate of 6mL / min 4 and 3mL / min of C 3 h 8 , using trimethylaluminum TMA with a flow rate of 1500mL / min as a dopant, and a growth pressure of 40mbar;

[0036] 3) Growth of epitaxial layer

[0037] a Growth: 40L / min flow rate of hydrogen, 10mL / min SiH 4 and 5mL / min of C 3 h 8 Pass it into the reaction chamber, keep the temperature at 1650°C and the pressure at 40mbar, and use trimethylaluminum TMA at a flow rate of 800mL / min as the dopant to grow an epitaxial lay...

Embodiment 2

[0042] A method for preparing a P-type low-defect thickness 30um silicon carbide epitaxial wafer, comprising the following steps:

[0043] 1) Etching the substrate online: place a 4H-SiC substrate in the reaction chamber, vacuumize, and feed in hydrogen gas at a flow rate of 40L / min and HCl at a flow rate of 5L / min. The pressure in the reaction chamber is 40mbar and the temperature is 1680°C. minute;

[0044] 2) Growth of the buffer layer: Stop feeding HCl, lower the temperature to 1650°C, and feed SiH with a flow rate of 6mL / min 4 and 3mL / min of C 3 h 8 , using trimethylaluminum TMA with a flow rate of 1500mL / min as a dopant, and a growth pressure of 40mbar;

[0045] 3) Growth of epitaxial layer

[0046] a Growth: 40L / min flow rate of hydrogen, 10mL / min SiH 4 and 5mL / min of C 3 h 8 Pass it into the reaction chamber, keep the temperature at 1650°C and the pressure at 40mbar, and use trimethylaluminum TMA at a flow rate of 800mL / min as the dopant to grow an epitaxial lay...

Embodiment 3

[0054] A method for preparing a P-type low-defect silicon carbide epitaxial wafer with a thickness of 80um, comprising the following steps:

[0055] 1) Etching the substrate online: place a 4H-SiC substrate in the reaction chamber, vacuumize, and feed in hydrogen gas at a flow rate of 40L / min and HCl at a flow rate of 5L / min. The pressure in the reaction chamber is 40mbar and the temperature is 1680°C. minute;

[0056] 2) Growth of the buffer layer: Stop feeding HCl, lower the temperature to 1650°C, and feed SiH with a flow rate of 6mL / min 4 and 3mL / min of C 3 h 8 , using trimethylaluminum TMA with a flow rate of 1500mL / min as a dopant, and a growth pressure of 40mbar;

[0057] 3) Growth of epitaxial layer

[0058] a Growth: 40L / min flow rate of hydrogen, 10mL / min SiH 4 and 5mL / min of C 3 h 8 Pass it into the reaction chamber, keep the temperature at 1650°C and the pressure at 40mbar, and use trimethylaluminum TMA at a flow rate of 800mL / min as the dopant to grow an epi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com