Compound crystalline sweetener and preparation method thereof

A technology for compounding sweeteners and sweeteners, applied in food preparation, food science, application and other directions, can solve the problems of failure to remove, reduce the application range of sweeteners, affect process operations, etc., and achieve suitable sweetness, The effect of increasing the number of bifidobacteria in the body and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

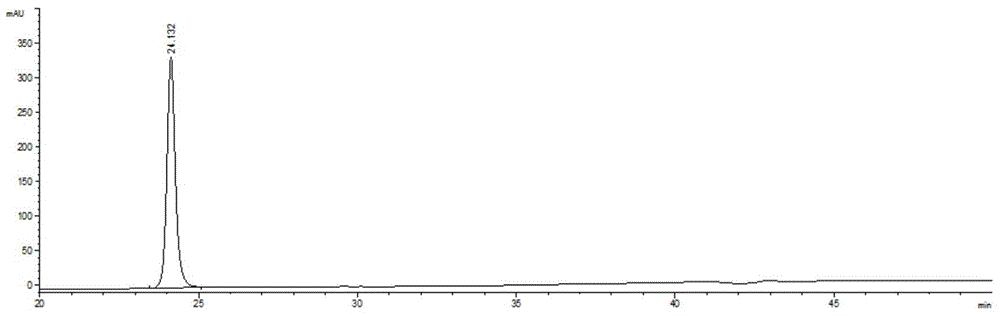

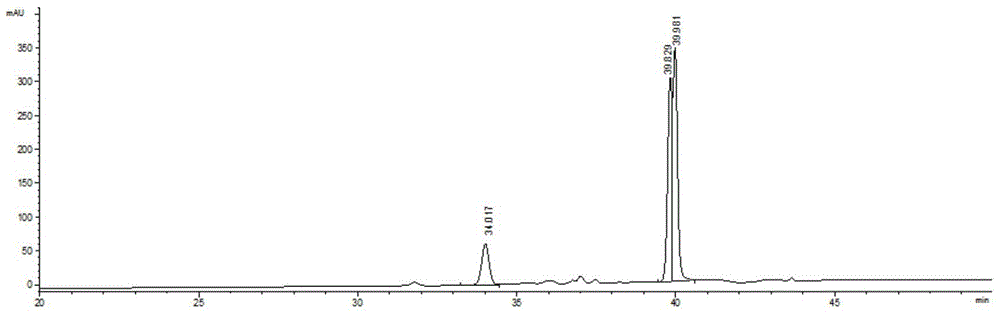

Image

Examples

Embodiment 1

[0051] 1) Take 100 g of fresh Momordica grosvenori fruit with a fruit age of about 90 days (guarantee the content of mogroside V), wash, crush, add pure water according to the solid-liquid mass ratio of 1:8, soak at room temperature for 1 hour, and then reflux at 80 °C Heating and extracting for 3 times, 1h each time, collecting the extract, using membrane concentration technology to concentrate, removing 70% of the water to obtain a concentrate;

[0052] 2) adding 3 times the mass of 95% (mass fraction) ethanol to the concentrate obtained in step 1), mixing, centrifuging, removing impurities such as polysaccharides and proteins, and obtaining a supernatant;

[0053] 3) the supernatant obtained in step 2) is concentrated under vacuum and low pressure to remove ethanol, and the obtained solution is placed in an ultrafiltration centrifuge cup with a molecular weight cut-off of 3000 Daltons, centrifuged for 30min at a rotating speed of 4500rpm, and the filtrate is collected and me...

Embodiment 2

[0063] 1) Take 500g of fresh Momordica grosvenori fruit with a fruit age of about 85 days (guarantee mogroside V content), wash, crush, add pure water according to the solid-liquid mass ratio of 1:8, soak at room temperature for 1 hour, and then reflux at 80°C Heating and extracting for 3 times, 1h each time, collecting the extract, using membrane concentration technology to concentrate, removing 70% of the water to obtain a concentrate;

[0064] 2) adding 3 times the mass of 95% (mass fraction) ethanol to the concentrate obtained in step 1), mixing, centrifuging, removing impurities such as polysaccharides and proteins, and obtaining a supernatant;

[0065] 3) the supernatant obtained in step 2) is concentrated under vacuum and low pressure to remove ethanol, and the obtained solution is placed in an ultrafiltration centrifuge cup with a molecular weight cut-off of 3000 Daltons, centrifuged for 30min at a rotating speed of 4500rpm, and the filtrate is collected and merged;

...

Embodiment 3

[0075] 1) Take 1000g of fresh Luo Han Guo fruit with a fruit age of about 80 days (to ensure the content of mogroside V), wash and crush, add pure water according to the solid-liquid mass ratio of 1:8, soak at room temperature for 1 hour, and then reflux at 80°C Heating and extracting 3 times, 1 hour each time, collecting the extract, concentrating using membrane concentration technology, removing 70% of the water, and obtaining the concentrate;

[0076] 2) Add 3 times the mass of 95% (mass fraction) ethanol to the concentrated solution obtained in step 1), mix well, and centrifuge to remove impurities such as polysaccharides and proteins to obtain a supernatant;

[0077] 3) Concentrating the supernatant obtained in step 2) under vacuum and low pressure, removing ethanol, placing the obtained solution in an ultrafiltration centrifuge cup with a molecular weight cut-off of 3000 Daltons, centrifuging at a speed of 4500rpm for 30min, collecting and merging the filtrate;

[0078] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mwco | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com