Poly(L-lactide-co-epsilon-caprolactone)nano-fiber nerve conduit and preparation method thereof

A nanofiber and nerve conduit technology, applied in the field of poly(L-lactide-co-ε-caprolactone) nanofiber nerve conduit and preparation, can solve problems such as difficulty in taking the tube and achieve good biocompatibility , complete structure, high matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

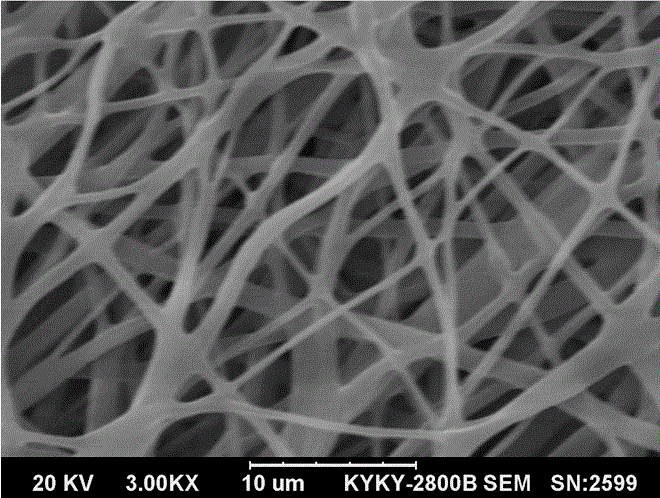

[0022] (1) Weigh 0.5g poly(L-lactide-co-ε-caprolactone) (molecular weight 100,000, molar ratio of L-lactide and ε-caprolactone is 80 / 20), dissolve in In 4ml of tetrahydrofuran and N,N-dimethylformamide mixed solvent, the volume ratio of tetrahydrofuran and N,N-dimethylformamide is 70 / 30, and a polymer solution with a concentration of 0.125g / ml is prepared;

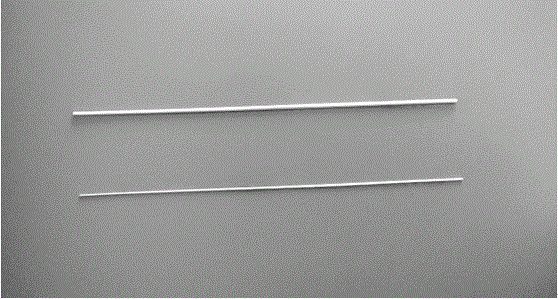

[0023] (2) Immerse a metal rod with a diameter of 2mm in a gelatin solution with a concentration of 0.02g / ml, take it out and dry it, and form a gelatin film on the outer layer of the metal rod;

[0024] (3) Set the spinning parameters and perform electrospinning, the spinning voltage is 10KV, the spinning speed is 2ml / h, and the receiving distance is 10cm;

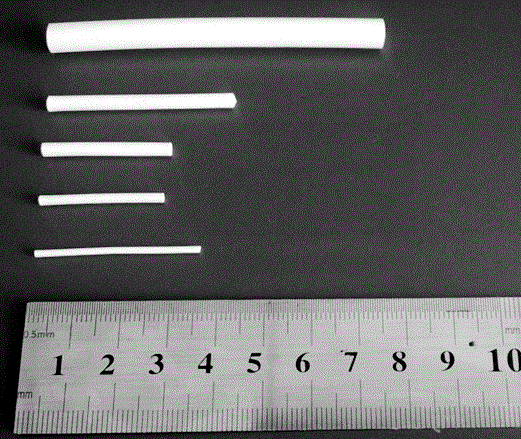

[0025] (4) Take off the metal rod after spinning for 1 hour, put it in 30°C water, dissolve the gelatin film covering the metal rod, and take off the nerve guide. The inner diameter of the prepared nerve guide is 2 mm, and the length is 5 cm. The wall thickness is 0....

Embodiment 2

[0027] (1) Weigh 1g poly(L-lactide-co-ε-caprolactone) (molecular weight 300,000, the molar ratio of L-lactide and ε-caprolactone is 70 / 30), dissolve it in 10ml In the mixed solvent of tetrahydrofuran and N,N-dimethylformamide, the volume ratio of tetrahydrofuran and N,N-dimethylformamide is 50 / 50, and a polymer solution with a concentration of 0.1g / ml is prepared;

[0028] (2) Immerse a metal rod with a diameter of 5mm in a gelatin solution with a concentration of 0.05g / ml, take it out and dry it, and form a gelatin film on the outer layer of the metal rod;

[0029] (3) Set the spinning parameters and perform electrospinning, the spinning voltage is 15KV, the spinning speed is 0.8ml / h, and the receiving distance is 15cm;

[0030] (4) Take off the metal rod after spinning for 5 hours, put it in 40°C water, dissolve the gelatin film covering the metal rod, and take off the nerve guide. The inner diameter of the prepared nerve guide is 5 mm, and the length is 10 cm. The wall thi...

Embodiment 3

[0032] (1) Weigh 2g poly(L-lactide-co-ε-caprolactone) (molecular weight of 500,000, the molar ratio of L-lactide and ε-caprolactone is 50 / 50), dissolve in 15ml In the mixed solvent of tetrahydrofuran and N,N-dimethylformamide, the volume ratio of tetrahydrofuran and N,N-dimethylformamide is 60 / 40, and a polymer solution with a concentration of 0.13g / ml is prepared;

[0033] (2) Immerse a metal rod with a diameter of 10mm in a gelatin solution with a concentration of 0.1g / ml, take it out and dry it, and form a gelatin film on the outer layer of the metal rod;

[0034] (3) Set the spinning parameters and perform electrospinning, the spinning voltage is 20KV, the spinning speed is 2ml / h, and the receiving distance is 20cm;

[0035] (4) After spinning for 6 hours, remove the metal rod, place it in 50°C water, dissolve the gelatin film covering the metal rod, and remove the nerve guide. The inner diameter of the prepared nerve guide is 10 mm, and the length is 8 cm. The wall thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com