Preparation method for magnetic carbon aerogel

A carbon airgel and magnetic technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of toxicity in the preparation process and high cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: the preparation method of the magnetic carbon airgel of the present embodiment, carry out according to the following steps:

[0020] 1. Weigh carboxymethyl cellulose sodium, glucono-δ-lactone and ferric chloride; add carboxymethyl cellulose sodium and glucono-δ-lactone into water, stir until dissolved, and obtain gel solution; ferric trichloride is dissolved in distilled water, and the pH value is adjusted to be neutral with ammonia water to obtain a neutral ferric chloride solution; the neutral ferric chloride solution is added to the colloidal liquid, and after stirring evenly, Stand at room temperature to obtain a gel;

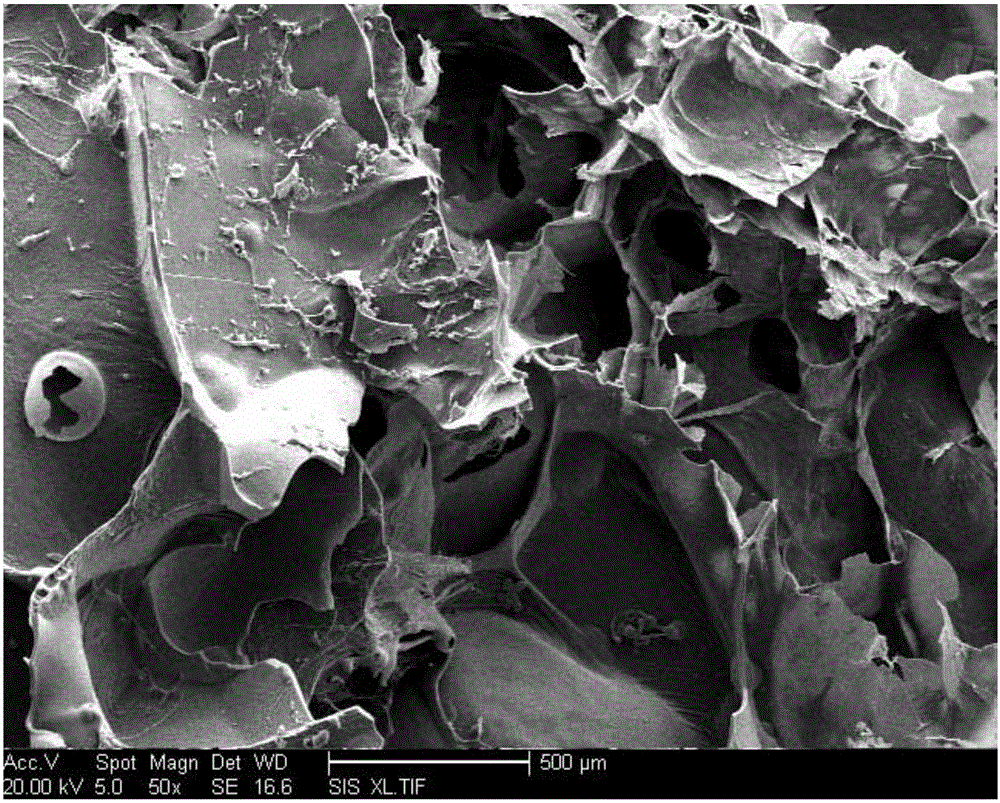

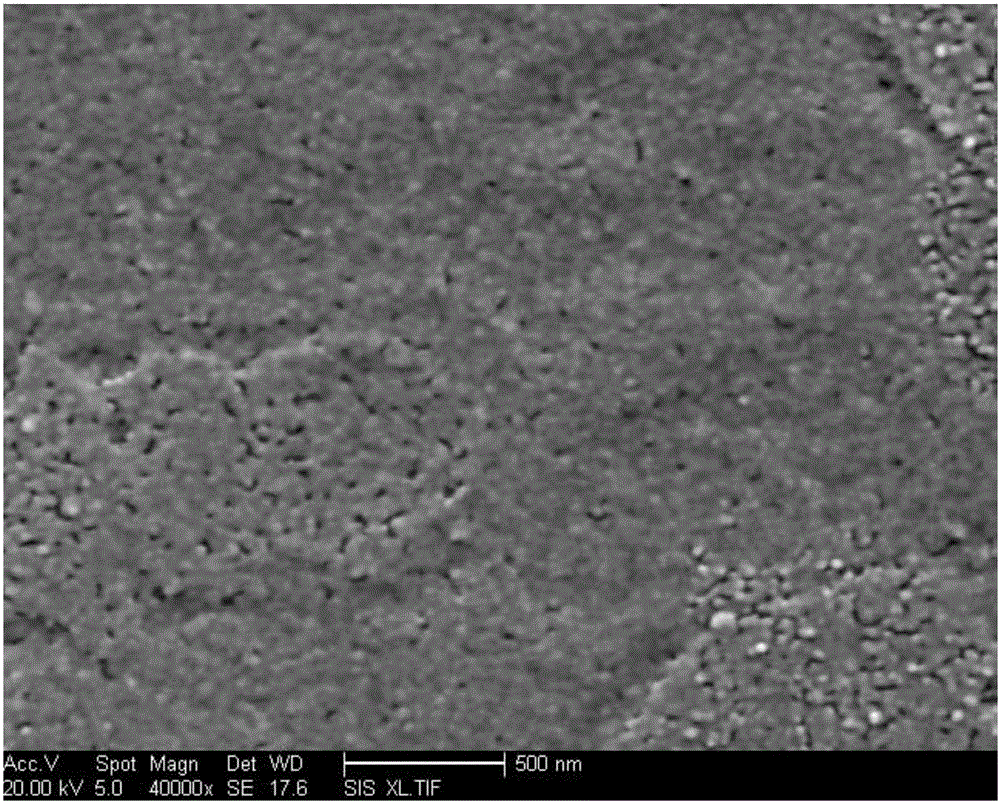

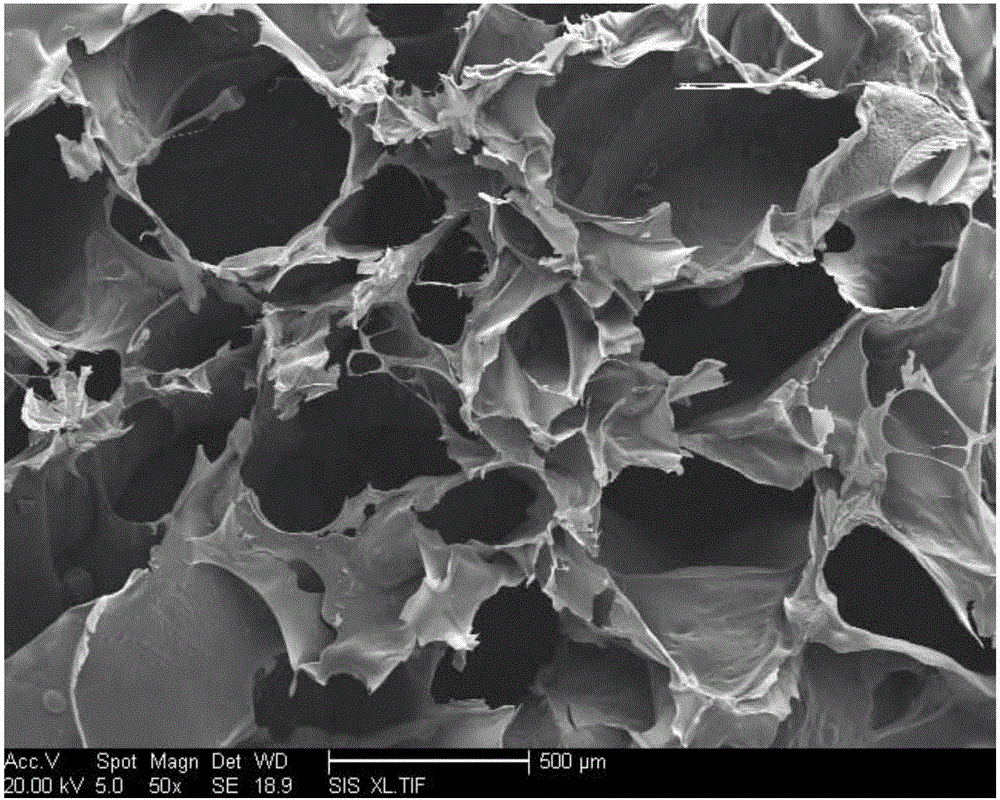

[0021] 2. After freezing the gel obtained in step 1, put it into a vacuum freeze dryer with a temperature of -50°C to -10°C to freeze-dry to obtain sodium carboxymethylcellulose aerogel;

[0022] Three, the sodium carboxymethyl cellulose aerogel that step 2 obtains is placed in the vacuum tube type heating furnace, feeds N ...

specific Embodiment approach 2

[0023] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, the mass ratio of carboxymethyl cellulose sodium to glucono-δ-lactone is 1: (0.5~0.7), carboxymethyl cellulose The mass ratio of plain sodium to ferric chloride is 1: (0.2-1); others are the same as in Embodiment 1.

specific Embodiment approach 3

[0024] Specific embodiment three: what this embodiment is different from specific embodiment one or two is that in step one, the sum of the quality of sodium carboxymethyl cellulose and glucono-delta-lactone and the volume ratio of water are 1g: (15 ~35) mL; others are the same as the specific embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com