Method for restoring organic contaminated soil by using ceramsite preparation process

A technology of organic pollution and ceramsite, which is applied in the field of contaminated soil remediation, can solve the problems of high treatment cost, affect the treatment progress, and long desorption time, and achieve the effects of high efficiency, light weight and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

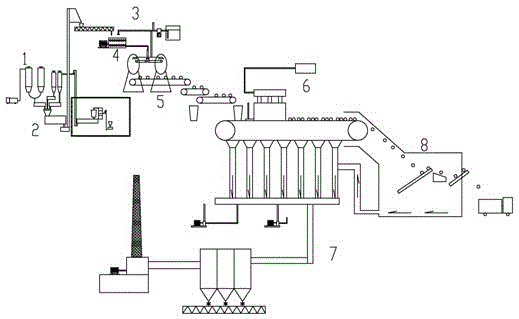

[0043] Implementation case: In this example, the amount of fly ash added accounts for 12% of the mass of the organically polluted soil, and the sintering temperature is 1180~1200°C. The preparation method steps are as follows:

[0044] a. Dry the organic contaminated soil in an oven (in the storage system) at 90-110°C;

[0045] b. The ball mill (in the storage system 1) crushes and grinds the organic contaminated soil described in step (a), and sieves it through a 100-mesh sieve (in the storage system 1);

[0046] c. The metering and feeding system 2 mixes the organic polluted soil powder and fly ash sieved in step (b) evenly in proportion, and transports them to the stirring nucleation system 4, adds water and mixes them for nucleation, and then in the double ball forming machine ( In the ball forming and distributing system 5), the formed blank is produced and transported to the secondary drying chamber (in the ignition sintering system 6);

[0047] d. Preheating sintering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com