Preparation method of purple ceramic pigment with cobalt-silicon olivine structure

A technology of olivine structure and ceramic pigment, applied in the field of ceramic pigment, can solve the problems of unsuitability for industrial application, long ball milling time, large powder particles, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

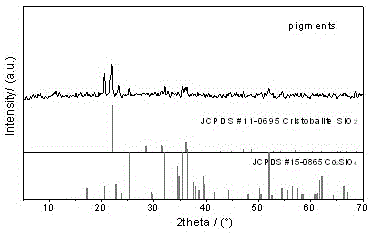

Image

Examples

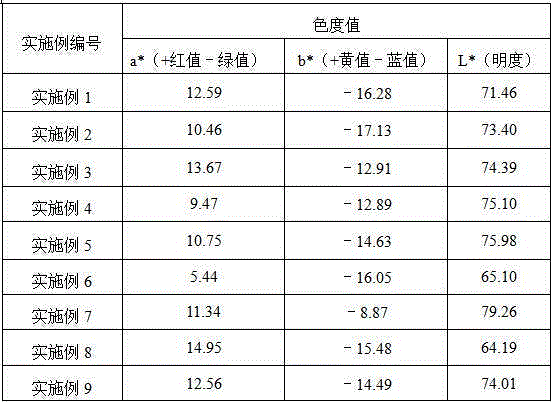

Embodiment 1

[0027] Dissolve 4.80 g of cobalt chloride hexahydrate in 5 mL of deionized water, stir to dissolve; then add 20 mL of ethyl orthosilicate to 20 mL of ethanol and 30 mL of deionized aqueous solution, heat and stir in a water bath at 60 ° C, so that the ethyl orthosilicate is fully alcoholized solution and hydrolysis; add the prepared cobalt chloride hexahydrate solution dropwise into the silica sol, after complete dropwise addition, continue to stir in a water bath at 60°C, add 5wt% mineralizer NaF, and adjust the pH value of the system with hydrochloric acid 1, continue to stir until a stable cobalt-silica gel system is formed, dry to obtain the initial dry gel powder, then calcinate the powder at 1000°C for 2 hours, and cool to obtain a uniformly distributed cobalt-silica olivine purple color material.

Embodiment 2

[0029] Dissolve 1.92 g of cobalt chloride hexahydrate in 5 mL of deionized water, stir to dissolve; then add 20 mL of ethyl orthosilicate to 20 mL of ethanol and 30 mL of deionized aqueous solution, heat and stir in a water bath at 60 ° C, so that the ethyl orthosilicate is fully alcoholized solution and hydrolysis; add the prepared cobalt chloride hexahydrate solution dropwise into the silica sol, after complete dropwise addition, continue to stir in a water bath at 60°C, and adjust the pH of the system to 6 with 3M NaOH solution until a stable cobalt The silica gel system is dried to obtain the initial powder, and then the powder is calcined at 1000°C for 1 hour, and then cooled to obtain a cobalt-silicon olivine purple pigment with uniform distribution and bright color.

Embodiment 3

[0031] Dissolve 4.80 g of cobalt chloride hexahydrate in 5 mL of deionized water, stir to dissolve; then add 20 mL of ethyl orthosilicate to 20 mL of ethanol and 30 mL of deionized aqueous solution, heat and stir in a water bath at 60 ° C, so that the ethyl orthosilicate is fully alcoholized solution and hydrolysis; add the prepared cobalt chloride hexahydrate solution dropwise into the silica sol, after complete dropwise addition, continue to stir in a water bath at 60°C, add 5wt.% mineralizer NaF, and adjust the pH of the system with hydrochloric acid The value is 1 until a stable cobalt-silica gel system is formed, dried to obtain the initial powder, and then the powder is calcined at 1200°C for 1 hour, and cooled to obtain a cobalt-silicon olivine purple pigment with a good reddish hue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com