Flue-cured tobacco bio-organic fertilizer and preparation method thereof

A bio-organic fertilizer and flue-cured tobacco technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as the insignificant effect of tobacco planting, and achieve the effects of improving resistance to rhizome diseases, preventing pollution, and improving absorption and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

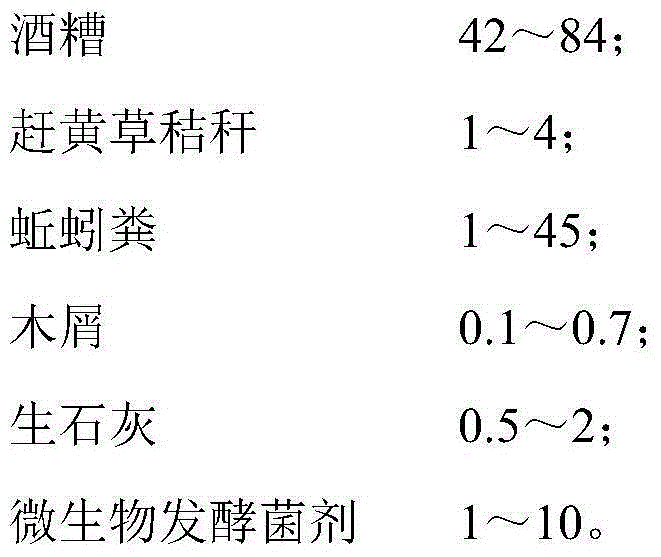

[0026] (1) a kind of flue-cured tobacco biological organic fertilizer, it is made up of the raw material of following weight portion:

[0027]

[0028] The nutrient mass percentages of the flue-cured tobacco bio-organic fertilizer are as follows: 60.0% organic matter, 3.0% nitrogen, 0.3% phosphorus, and 1.5% potassium.

[0029] (2) the preparation method of described flue-cured tobacco biological organic fertilizer comprises the steps:

[0030] S1. Weigh each raw material according to the formula, set aside;

[0031] S2. After mixing distiller's grains, yellow grass stalks, vermicompost, sawdust, and quicklime, add a decomposing bacteria agent and mix evenly to obtain a mixed fermentation material;

[0032] S3. Stacking and fermenting the mixed fermented material at 50°C for 25 days to obtain clinker;

[0033] S4. After the clinker is pulverized, it is sieved with a sieve with a mesh number of 50 to obtain flue-cured tobacco bio-organic fertilizer.

Embodiment 2

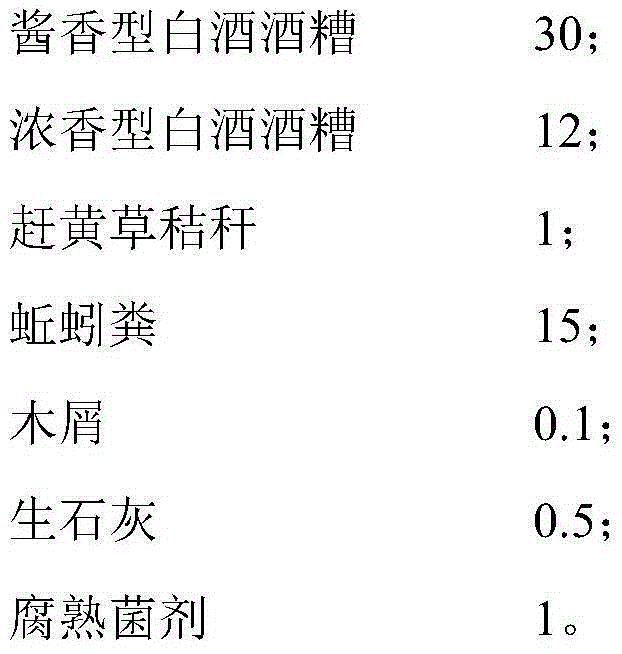

[0035] (1) a kind of flue-cured tobacco biological organic fertilizer, it is made up of the raw material of following weight portion:

[0036]

[0037] The nutrient mass percentages of the flue-cured tobacco bio-organic fertilizer are as follows: 70.0% organic matter, 2.0% nitrogen, 0.1% phosphorus, and 2.0% potassium.

[0038] (2) the preparation method of described flue-cured tobacco biological organic fertilizer comprises the steps:

[0039] S1. Weigh each raw material according to the formula, set aside;

[0040] S2. After mixing distiller's grains, yellow grass stalks, vermicompost, sawdust, and quicklime, add decomposing bacteria agent and Bacillus pumilus and mix evenly to obtain a mixed fermentation material;

[0041] S3. stacking and fermenting the mixed fermented material at 55° C. for 27 days to obtain clinker;

[0042] S4. After the clinker is pulverized, it is sieved with a sieve with a mesh number of 60 to obtain flue-cured tobacco bio-organic fertilizer.

Embodiment 3

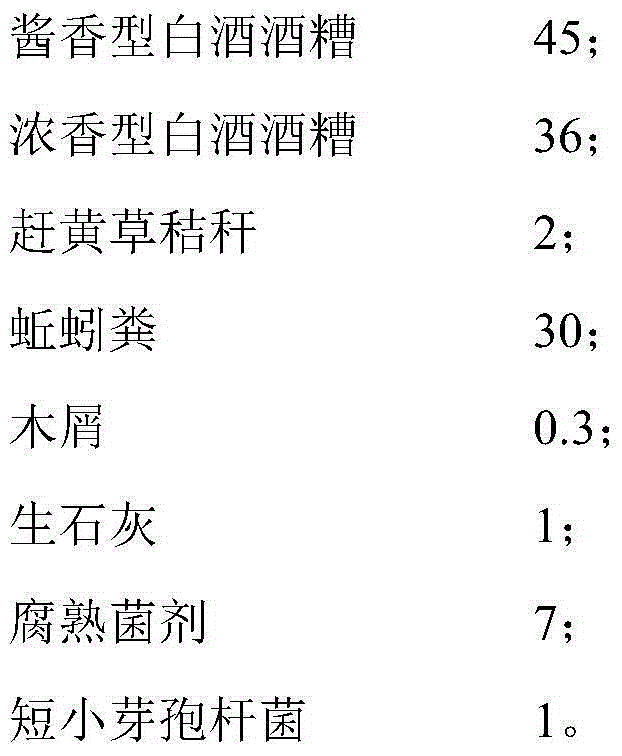

[0044] (1) a kind of flue-cured tobacco biological organic fertilizer, it is made up of the raw material of following weight portion:

[0045]

[0046] The nutrient mass percentage content of the flue-cured tobacco bio-organic fertilizer is as follows: organic matter is 50.0%, nitrogen is 1.0%, phosphorus is 0.5%, and potassium is 1.0%.

[0047] (2) the preparation method of described flue-cured tobacco biological organic fertilizer comprises the steps:

[0048] S1. Weigh each raw material according to the formula, set aside;

[0049] S2. After mixing distiller's grains, yellow grass straw, vermicompost, sawdust, and quicklime, add Bacillus pumilus and mix evenly to obtain a mixed fermentation material;

[0050] S3. Stacking and fermenting the mixed fermented material at 60°C for 29 days to obtain clinker;

[0051] S4. After the clinker is pulverized, it is sieved with a sieve with a mesh number of 70 to obtain flue-cured tobacco bio-organic fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com