Preparation method for biomass fuel

A biomass fuel and raw material technology, which can be applied to biofuels, waste fuels, fuels, etc., can solve the problems of difficult combustion and slow combustion, and achieve the effects of sufficient and stable combustion, increased calorific value, and strong thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

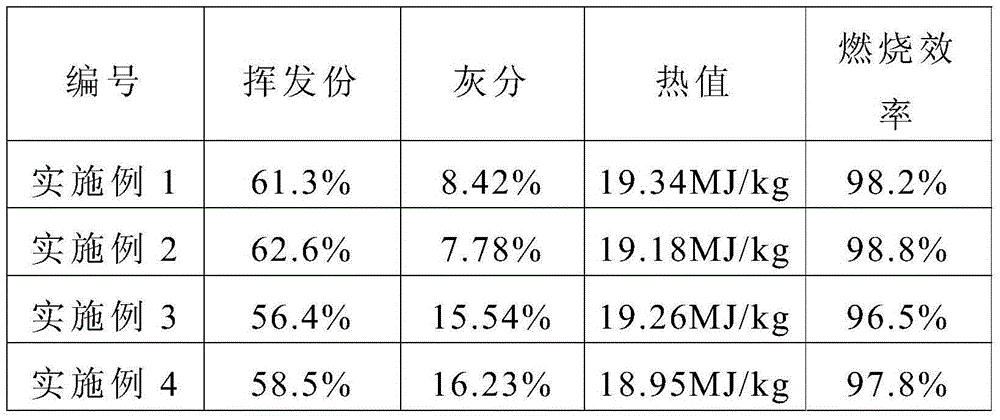

Examples

preparation example Construction

[0024] The preparation method of biomass fuel provided by the present invention uses the following raw materials: 30%-40% of chaff, 30-40% of straw, 1%-1.5% of oxidant, 2%-3.5% of combustion aid, and 10% of binder -15%, loosening agent 12%-15%, wherein said loosening agent is activated carbon;

[0025] Its preparation method is as follows:

[0026] Step 1. Drying the chaff and crushing it to 50-100 mesh with a crusher; drying the straw and chopping it to 50-100 mesh; crushing the bulking agent to 0.5mm-1mm;

[0027] Step 2, mixing the chaff powder and straw powder processed in the above step 1 with the corresponding proportion of oxidizing agent and combustion accelerant;

[0028] Step 3, add a corresponding proportion of loosening agent to the raw materials prepared in the above step 2 and mix evenly;

[0029] Step 4: Add a corresponding proportion of binder to the raw materials prepared in the above step 3 and mix evenly, and process the uniformly mixed raw materials with ...

Embodiment 1

[0031] The raw materials used are: 30% chaff, 40% straw, 1% potassium permanganate as an oxidant, 0.8% alumina as a combustion aid, 0.8% iron oxide, 0.4% magnesium powder, and 12% as a binder. % bentonite, loosening agent is 15% activated carbon; dry the chaff and crush it to 100 mesh, dry the straw to 100 mesh; crush the activated carbon to 1mm; mix the processed chaff powder, straw powder and permanganate Potassium and magnesium powders are mixed evenly, then activated carbon is added and mixed evenly; bentonite is added to the raw materials prepared above, and then balls are formed by a pelletizing machine.

Embodiment 2

[0033] The raw materials used are: 40% chaff, 30% straw, 1% potassium chlorate as an oxidant, 0.8% aluminum oxide as a combustion aid, 0.8% iron oxide, 0.4% magnesium powder, and 12% as a binder. Bentonite and loosening agent are 15% coconut shell activated carbon; dry the chaff and crush it to 80 mesh, dry the straw to 80 mesh; crush the activated carbon to 0.8mm; mix the processed rice hull powder, straw powder with potassium chlorate, After the magnesium powder is mixed evenly, add coconut shell activated carbon and mix evenly; add bentonite to the above-mentioned prepared raw materials and use a pelletizing machine to form balls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com