Tablets containing Apremilast active ingredients and vitro dissolution determination method thereof

A method of determination, technology of tablets, applied in the field of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Tablet prescription (1000 formulation units):

[0048]

[0049]

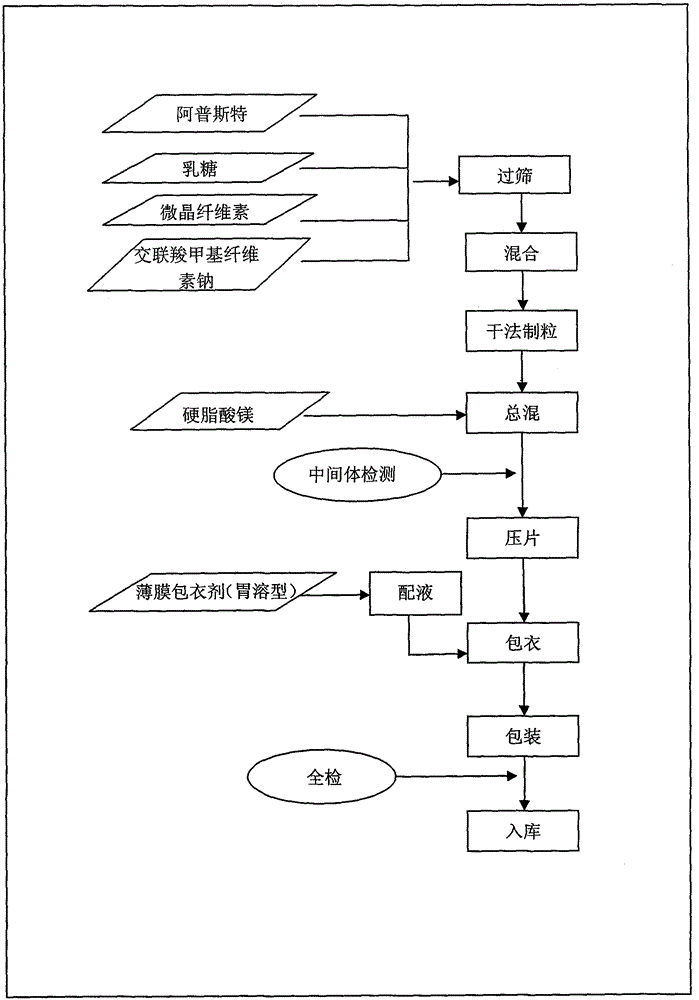

[0050] Preparation process (dry granulation and tabletting)

[0051] (1) Processing of raw and auxiliary materials: pass Apremilast, lactose, microcrystalline cellulose, and croscarmellose sodium through an 80-mesh sieve, and set aside.

[0052] (2) Mixing: Put Apremilast, lactose, microcrystalline cellulose and croscarmellose sodium in a high-speed mixing granulator, adjust the rotating speed to 150-200rpm, and mix for 15 minutes.

[0053] (3) Dry granulation: Put the mixed powder in a dry granulator, adjust the roller pressure to 2.0-4.0MPa, the roller speed to 10-15rpm, the cutter speed to 10-15rpm, and use a 20-30 mesh sieve for granulation , 20-30 mesh sieve for granulation.

[0054] (4) Total blending: Calculate the yield of granules after dry granulation, and then add converted lubricants and other additional auxiliary materials to the granules and mix evenly.

[0055] (5) Intermediate inspe...

Embodiment 2

[0059] Tablet prescription (1000 formulation units):

[0060]

[0061] Preparation process (dry granulation and tabletting)

[0062] (1) Processing of raw and auxiliary materials: pass Apremilast, lactose, microcrystalline cellulose, and croscarmellose sodium through an 80-mesh sieve, and set aside.

[0063] (2) Mixing: Put Apremilast, lactose, microcrystalline cellulose and croscarmellose sodium in a high-speed mixing granulator, adjust the rotating speed to 150-200rpm, and mix for 15 minutes.

[0064] (3) Dry granulation: Put the mixed powder in a dry granulator, adjust the roller pressure to 2.0-4.0MPa, the roller speed to 10-15rpm, the cutter speed to 10-15rpm, and use a 20-30 mesh sieve for granulation , 20-30 mesh sieve for granulation.

[0065] (4) Total blending: Calculate the yield of granules after dry granulation, and then add the converted lubricant and other external auxiliary materials to the granules and mix evenly.

[0066] (5) Intermediate inspection [co...

Embodiment 3

[0070] Tablet prescription (1000 formulation units):

[0071]

[0072] Preparation process (dry granulation and tabletting)

[0073] (1) Processing of raw and auxiliary materials: pass Apremilast, lactose, microcrystalline cellulose, and croscarmellose sodium through an 80-mesh sieve, and set aside.

[0074] (2) Mixing: Put Apremilast, lactose, microcrystalline cellulose and croscarmellose sodium in a high-speed mixing granulator, adjust the rotating speed to 150-200rpm, and mix for 15 minutes.

[0075] (3) Dry granulation: put the mixed powder in a dry granulator, adjust the roller pressure to 2.0-4.0MPa, the roller speed to 10-15rpm, the cutter speed to 10-15rpm, and use a 30-mesh sieve for granulation. Mesh sieve for whole grains.

[0076] (4) Total blending: Calculate the yield of granules after dry granulation, and then add converted lubricants and other additional auxiliary materials to the granules and mix evenly.

[0077] (5) Intermediate inspection [content, moi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com