High-calcium noodles and making method thereof

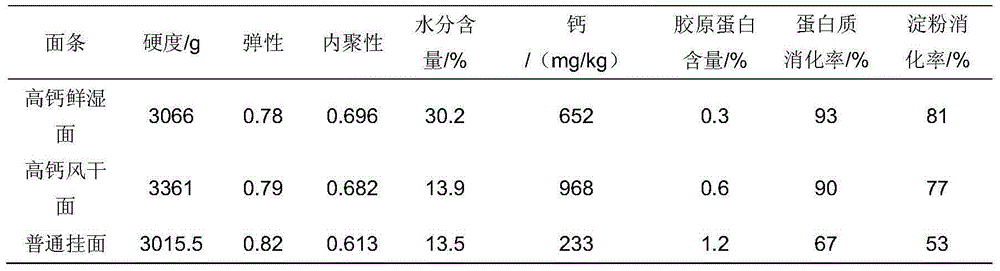

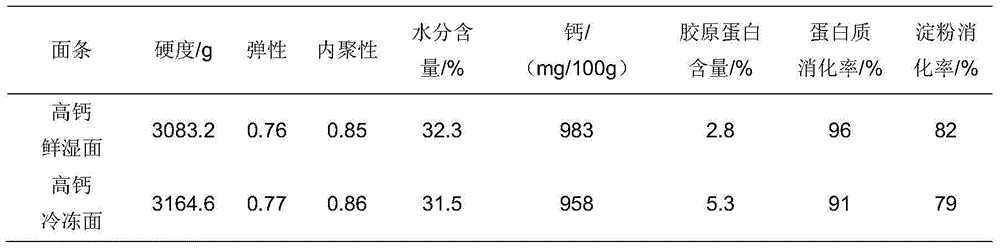

A production method and high-calcium technology, applied in the food field, can solve the problems of low protein digestibility and starch digestibility, unfavorable absorption of noodles, etc., and achieve the effects of facilitating absorption, better taste, and increasing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] First, weigh main ingredient 2 in proportion: 10 parts of commercially available chicken skeleton; auxiliary material 1: 0.2 part of bean dregs, 0.2 part of unsalted shrimp skin, 0.5 part of salt, 0.5 part of sugar, 0.5 part of ginger slices, and 1 part of vinegar. In embodiment 1-3, described 1 part is 1kg, carries out following operation respectively successively:

[0043] Cleaning: clean the commercially available chicken skeleton;

[0044] Broken and boiled soup: use a bone mud machine to crush the cleaned chicken skeleton to an equivalent diameter of less than 5mm to obtain a broken bone, mix the broken bone, auxiliary material 1, and 4 times the volume of water, boil at 121°C for 5 minutes, and cool to 46°C to get bone broth;

[0045] Weigh auxiliary materials 2 in proportion: 0.1 part of transglutaminase, 0.2 parts of flavor protease and compound protease, 0.01 part of lysine, 0.01 part of glutamic acid, 0.1 part of calcium lactate, sodium tripolyphosphate and s...

Embodiment 2

[0054] First, weigh the main ingredient 2 in proportion: 50 parts of pork ribs without meat in the market; auxiliary materials 1: 0.4 parts of bean dregs, 0.4 parts of unsalted shrimp skin, 2 parts of salt, 1 part of sugar, 1 part of ginger slices, 5 parts of vinegar, Do the following in turn:

[0055] Cleaning: Clean the pork ribs sold in the market;

[0056] Crush and make soup: Crush the cleaned pork ribs with a bone mud machine to an equivalent diameter of less than 2 mm to obtain broken bones, mix the broken bones, auxiliary material 1, and 4 times the volume of water, and boil at 100°C for 15 minutes. Cool to 50°C to obtain bone broth;

[0057] Weigh auxiliary materials 2 in proportion: 0.5 parts of transglutaminase, 0.8 parts of flavor protease and compound protease, 0.6 parts of lysine, 0.6 parts of glutamic acid, 0.5 parts of calcium lactate, sodium tripolyphosphate and sodium dihydrogen phosphate 0.4 parts each, 3 parts phosphated cross-linked starch, 0.2 parts edi...

Embodiment 3

[0066] The differences between this embodiment and Embodiment 1 are:

[0067] Described high-calcium noodles, raw material composition comprises:

[0068] Main ingredient 1: 100 parts of wheat flour;

[0069] Main ingredient 2: 30 parts of commercially available fish bones;

[0070] Accessories 1: 0.3 parts of bean dregs, 0.3 parts of unsalted shrimp skin, 1 part of salt, 0.7 parts of sugar, 0.7 parts of ginger slices, and 3 parts of vinegar;

[0071] Excipient 2: 0.3 parts of transglutaminase, 0.5 parts of flavor protease and compound protease, 0.3 parts of lysine, 0.3 parts of glutamic acid, 0.3 parts of calcium lactate, 0.3 parts of sodium tripolyphosphate and sodium dihydrogen phosphate, 2 parts of cross-linked hydroxypropyl starch, 0.1 part of edible alkali, and 0.3 part of konjac powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com