Preparation method of high-purity Ag-loading TiO2 full-mesoporous nanofiber

A nanofiber and high-purity technology, which is applied in the field of preparation of inorganic semiconductor photoelectric materials, can solve the problems of composite materials such as ineffective use of superiority, poor stability, and low specific surface area, and achieve enhanced photocatalytic performance, stable quality, The effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

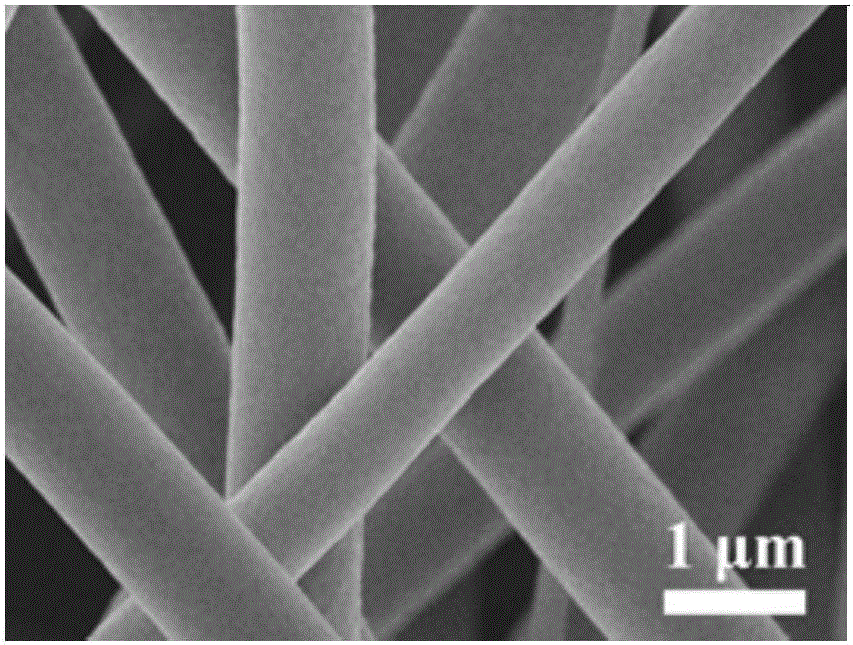

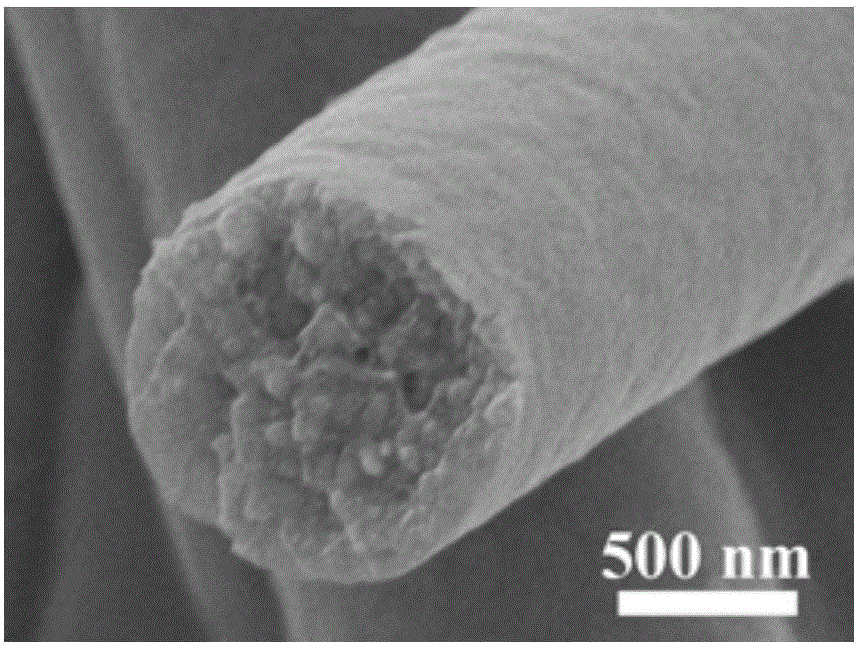

[0051] Weigh 0.7g of polyvinylpyrrolidone (PVP) and 4.0g of butyl titanate (TBOT) and dissolve them in a mixture of 7ml of absolute ethanol and 3ml of glacial acetic acid, stir and mix at room temperature for 10 hours, then add 0.4g of azodicarboxylate Isopropyl ester (foaming agent, DIPA) was continuously stirred for 1 hour to obtain a precursor spinning solution. After the spinning solution was left to stand, 6ml was measured and injected into a plastic needle tube, and placed on a micro-injection pump, and the injection speed was set at 1ml / h. The metal needle was used as the electrospinning anode, and the barbed wire was used as the cathode of the receiving material. The distance between the anode and the cathode was 20 cm. Electrospinning was performed at a high voltage of 15kV to prepare organic precursor fiber materials. Then the organic precursor fiber material is placed in a 60°C constant temperature oven to obtain a solid organic precursor fiber ( figure 1 and fig...

Embodiment 2

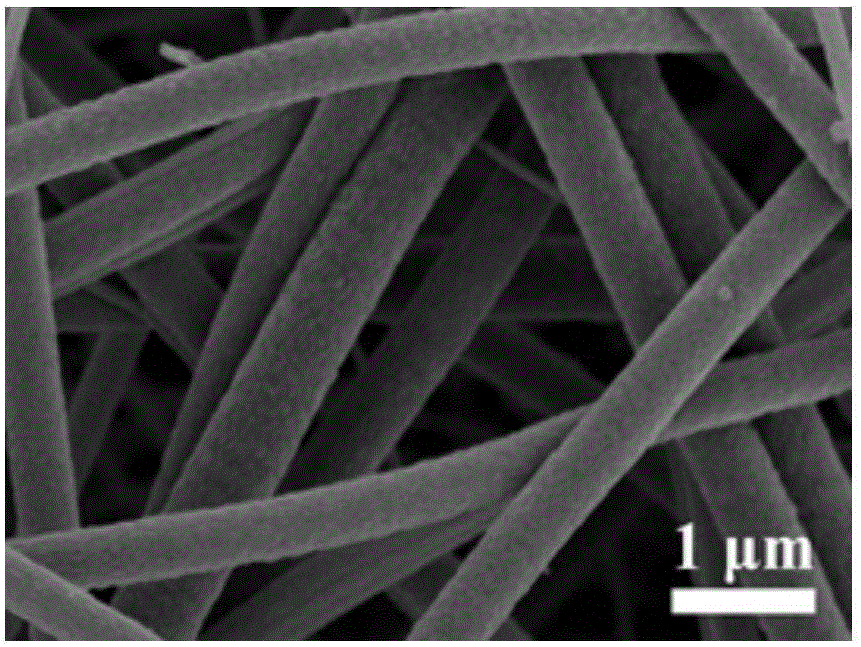

[0054] TiO 2 The preparation of all mesoporous nanofibers is the same as in Example 1, and the prepared TiO 2 Fully mesoporous nanofibers were dispersed in 50 ml of deionized water, followed by about 2.0 g of AgNO 3 Added to the above suspension to make Ag + The concentration is 0.24mol / L, under the condition of continuous stirring, the light is irradiated for 2h, after centrifugation, filtration and drying, the Ag-loaded TiO 2 Scanning electron microscopy (SEM) images of mesoporous nanofibers at different magnifications and magnifications are shown in Figure 11 and Figure 12 shown. Figure 11 The illustration in is the particle size distribution diagram of Ag nanoparticles, and the analysis and calculation shows that the average particle size is 42.8nm. Figure 13 Loading TiO for Ag 2The energy spectrum (EDS) of all mesoporous nanofibers is mainly composed of Ti, O and Ag elements, and the atomic ratio of Ag elements is 1.26at%; the results of Comparative Example 1 sh...

Embodiment 3

[0057] TiO 2 The preparation of all mesoporous nanofibers is the same as in Example 1, and the prepared TiO 2 Fully mesoporous nanofibers were dispersed in 50 ml of deionized water, followed by about 3.0 g of AgNO 3 Added to the above suspension to make Ag + The concentration is 0.36mol / L, under the condition of continuous stirring, the light is irradiated for 2h, after centrifugation, filtration and drying, the Ag-loaded TiO 2 Scanning electron microscopy (SEM) images of mesoporous nanofibers at different magnifications and magnifications are shown in Figure 14 and Figure 15 shown. Figure 14 The illustration in is the particle size distribution diagram of Ag nanoparticles. According to analysis and calculation, the average particle size is 68.9nm. Figure 16 Loading TiO for Ag 2 The energy spectrum (EDS) of all mesoporous nanofibers is mainly composed of Ti, O and Ag elements, and the atomic ratio of Ag elements is 2.14at%; the results of comparative example one and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com