Preparation method of powder metallurgy gear and sprocket

A powder metallurgy and gear technology, applied in the field of powder metallurgy, can solve the problems of increased pressure of re-pressing, increased die loss, etc., and achieve the effects of increasing density, increasing extrusion process, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] ① Prepare the raw materials, that is, the mixed powder of iron copper and carbon. The ratio is: atomized iron powder is 96.8%, carbon is 0.70%, copper powder is 2%, and then add lubricant with a content of 0.5%;

[0051] ②Compress the above mixed powder under a pressure of 600MPa to a density of 7.10g / cm 3 tooth (chain) wheel blank;

[0052] ③Sintering, the tooth (chain) wheel parts are sintered at a temperature of 1200°C, the sintering time is 20 minutes, and the sintering is carried out in a vacuum sintering furnace;

[0053] ④Annealing: the annealing temperature is 850°C; the atmosphere is nitrogen, the annealing holding time is 60 minutes, and the cooling rate from the annealing temperature to 300°C after annealing is 0.1°C / S;

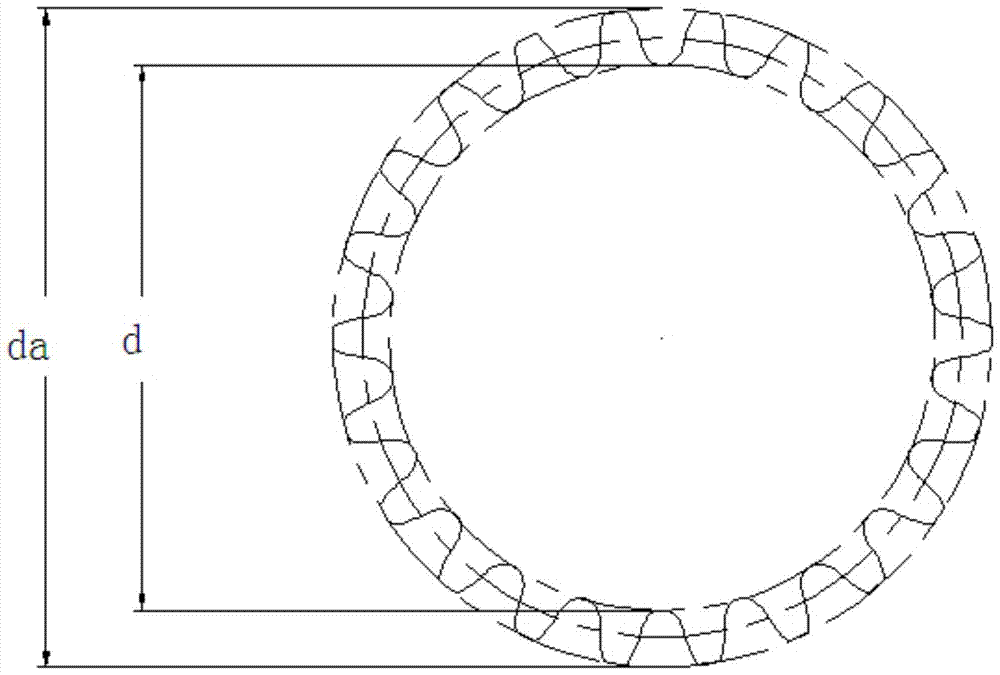

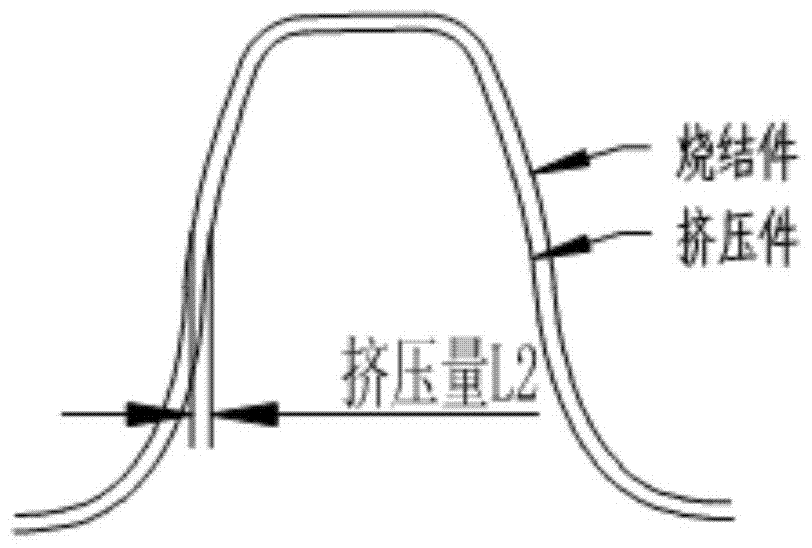

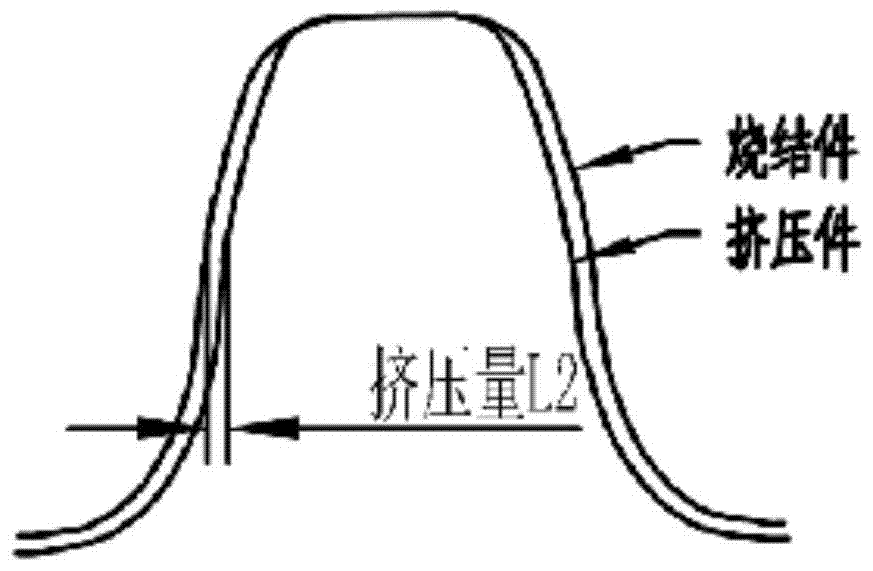

[0054] ⑤ Extrusion (finishing): Extrusion is carried out on a press modified by an extrusion molding machine or a finishing press, and the extrusion deformation L2 is (da-d) / 2×8%, while for the internal gear, then L2≥(d-da) / 2×2%, where da ...

Embodiment 2

[0058] ① Prepare the raw materials, that is, the mixed powder of iron, chromium, molybdenum and carbon. The ratio is: iron alloy powder (chromium is 3.0%, molybdenum is 0.5%, other unavoidable substances, less than 1%, iron is the balance) is 50 %, pure iron powder is 48.7%; carbon is 0.8%, and then add lubricant with a content of 0.5%;

[0059] ② Press the above mixed powder under a pressure of 600MPa to form a tooth (chain) wheel green body with a density of 7.2g / cm3.

[0060] ③Sintering, the tooth (chain) wheel parts are sintered at a temperature of 1120°C, the sintering time is 20 minutes, and the sintering is carried out in a sintering furnace based on nitrogen and the proportion of hydrogen is 10vol%;

[0061] ④Annealing: The annealing temperature is 850°C; the atmosphere is nitrogen, the annealing holding time is 60 minutes, and the cooling rate from the annealing temperature to 300°C after annealing is 0.1°C / S.

[0062] ⑤ Extrusion (finishing): Extrusion is carried ou...

Embodiment 3

[0065] ① Prepare the raw materials, that is, the mixed powder of iron, chromium, molybdenum and carbon. The ratio is: iron alloy powder (chromium is 17.0%, molybdenum is 1.0%, other unavoidable substances, less than 1%, iron is the balance) is 99.2 %; carbon is 0.3%, and then add a lubricant with a content of 0.5%;

[0066] ② Warm press the above mixed powder under a pressure of 600MPa to a density of 6.60g / cm 3 tooth (chain) wheel blank;

[0067] ③Sintering, the tooth (chain) wheel parts are sintered at a temperature of 1200°C, the sintering time is 60 minutes, the sintering is carried out in a vacuum sintering furnace, and annealed at 890°C for 60 minutes during the cooling stage after sintering, after annealing The cooling rate from the annealing temperature to 300°C is 0.15°C / S;

[0068] ④ Extrusion (finishing): Extrusion is performed on a press modified by an extrusion molding machine or a finishing press, and the extrusion deformation L2 is (da-d) / 2×5%;

[0069] ⑤Heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com