A rare earth permanent magnet material hydrogen resource recycling device and its application method

A rare earth permanent magnet and application method technology are applied in the fields of a hydrogen crushing device of a NdFeB permanent magnet material and a hydrogen resource recycling device of a rare earth permanent magnet material, which can solve the problem of excessive hydrogen recovery, high maintenance and operation cost, and use effect. Invisible and other problems, to achieve the effect of sensitive control, low maintenance cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

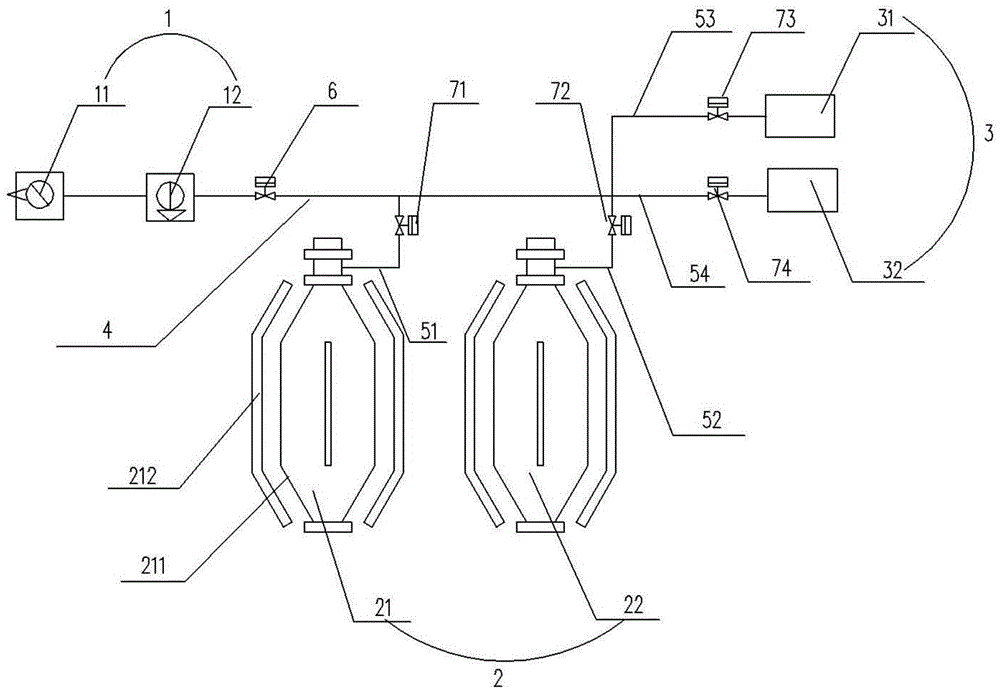

[0051] Such as figure 1 As shown, the present invention provides a hydrogen resource recycling device for rare earth permanent magnet materials, including a vacuum group 1, a reactor group 2 and a gas supply group 3 connected in series through a pipeline 4, wherein,

[0052] Vacuum group 1, it comprises mechanical pump 11 and Roots pump 12 in series, and described vacuum group communicates with described pipeline 4 through butterfly valve 6;

[0053] Reactor group 2, it comprises a first reactor 21 and a second reactor 22, and described first reactor 21 and described second reactor 22 communicate through first branch 51 and second branch 52 respectively The pipeline 4, the first branch 51 and the second branch 52 are respectively provided with a first solenoid valve 71 and a second solenoid valve 72; the first reaction kettle 21 and the second reaction The top of the kettle 22 is equipped with a cooling water device, and electric furnace wire and refractory materials are arra...

Embodiment 2

[0057] The present invention provides a hydrogen resource recycling device for rare earth permanent magnet materials, which includes a vacuum group 1, a reactor group 2 and a gas supply group 3 connected in series through a pipeline 4, wherein,

[0058] Vacuum group 1, it comprises mechanical pump 11 and Roots pump 12 in series, and described vacuum group communicates with described pipeline 4 through butterfly valve 6;

[0059] Reactor group 2, it comprises two first reactors 21 and two second reactors 22, described two first reactors 21 and described two second reactors 22 pass through two first branches respectively 51 and two second branches 52 communicate with the pipeline 4, and the two first branches 51 and the two second branches 52 are respectively provided with two first solenoid valves 71 and two second solenoid valves 71 Two electromagnetic valves 72; the tops of the two first reactors 21 and the two second reactors 22 are equipped with cooling water devices, and e...

Embodiment 3

[0063] An application method of a rare earth permanent magnet material hydrogen resource recycling device, comprising the following steps:

[0064] Step 1, filling the first rare earth permanent magnet material to be hydrogen absorbed into the first reaction kettle 21, filling the second rare earth permanent magnet material to be dehydrogenated into the second reaction kettle 22, the first reaction The weight ratio of the first rare earth permanent magnet material in the kettle 21 and the second rare earth permanent magnet material of the second reaction kettle 22 is 1:1;

[0065] Step 2: Open the butterfly valve 6, the first solenoid valve 71 and the second solenoid valve 72, start the mechanical pump 11 and the Roots pump 12 to vacuum the system until the vacuum degree is less than 0.1Pa, and close the butterfly valve 6 , Mechanical pump 11 and Roots pump 12;

[0066] Step 3, start the heating system of the first reaction kettle 21, so that the temperature in the first reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com