Fast-growing wood flame-retardant laminated board and production method thereof

A production method and technology of fast-growing wood, applied in the direction of layered products, wooden veneer joints, chemical instruments and methods, etc., can solve the problems of mechanical strength decline, difficulty in meeting requirements, and single performance of veneer laminated boards. Achieving the effects of less decrease in material properties, higher viscosity, and shorter soaking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

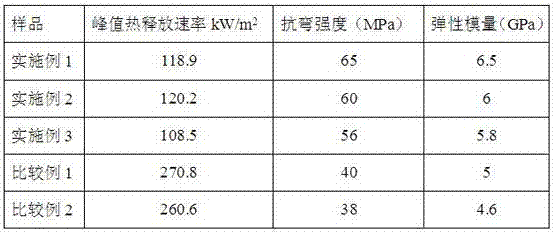

Examples

Embodiment 1

[0024] Poplar flame-retardant laminated board, including poplar flame-retardant core layer and its upper and lower flame-retardant reinforced surface layers, each material layer is hot-pressed and glued, and the poplar flame-retardant core layer is poplar veneer treated by impact impregnation with phosphorus-nitrogen flame retardants In the laminated board, the flame-retardant reinforced surface layer is a glass fiber cloth impregnated with a flame-retardant phenolic adhesive.

[0025] The production method of poplar fire-retardant laminated board comprises the following steps,

[0026] (1) Preparation of poplar fire retardant core layer

[0027] Select a poplar veneer with a thickness of 1.2-2.0mm and dry it until the moisture content is less than 5%; soak it in a phosphorus-nitrogen flame retardant at 40°C for 1 hour, the flame retardant is in a flowing state, and repeatedly impact the veneer. After treatment, dry it so that the moisture content is lower than 10%; then appl...

Embodiment 2

[0033] Poplar flame-retardant laminated board, including poplar flame-retardant core layer and upper and lower flame-retardant reinforced surface layers, each material layer is hot-pressed and glued, and the poplar flame-retardant core layer is poplar veneer layer impregnated with borate flame retardant The flame-retardant reinforced surface layer is a hemp fiber cloth impregnated with a flame-retardant melamine adhesive.

[0034] The production method of poplar fire-retardant laminated board comprises the following steps,

[0035] (1) Preparation of poplar fire retardant core layer

[0036] Select a poplar veneer with a thickness of 1.2-2.0mm, dry it until the moisture content is less than 5%; soak it in a borate flame retardant at 50°C for 3 hours, the flame retardant is in a flowing state, and repeatedly impact the veneer, After treatment, dry it so that the moisture content is lower than 10%; then apply melamine-modified urea-formaldehyde glue to the even-numbered veneers...

Embodiment 3

[0042] Eucalyptus flame-retardant laminated board, including eucalyptus flame-retardant core layer and its upper and lower flame-retardant reinforced surface layers, each material layer is hot-pressed and glued. The wood veneer laminated board, the flame retardant reinforced surface layer is hemp fiber cloth impregnated with phosphorus nitrogen series flame retardant phenolic adhesive.

[0043] The production method of eucalyptus fire-retardant laminated board comprises the following steps,

[0044] (1) Preparation of fire retardant core layer of eucalyptus

[0045] Select a eucalyptus veneer with a thickness of 1.2-2.0mm, dry it until the moisture content is less than 5%; soak it in a phosphorus-nitrogen series flame retardant at 60°C for 2 hours, the flame retardant is in a flowing state, and repeatedly impact the veneer, After treatment, dry it so that the moisture content is lower than 10%; then apply urea-formaldehyde glue to both sides of the even-numbered veneers, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com