Early-strength polycarboxylate superplasticizer and preparation method thereof

A polycarboxylate-based, early-strength type technology, applied in the field of building materials, can solve the problems that the product performance cannot meet the setting time and early-strength requirements of special concrete at the same time, and the process is not easy to control, so as to achieve superior early-strength performance and shorten the Clotting time, easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

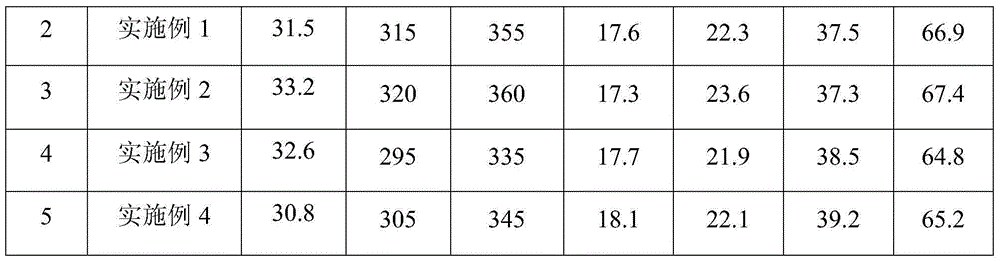

Embodiment 1

[0025] In parts by weight, 200 parts of CH 2 =CH(CH 3 )CH 2 CH 2 O(CH 2 CH 2 O) 70 CH 2 CH 3 CHO H, 5 parts of acrylic acid, 2 parts of diallyl dimethyl ammonium chloride, 2 parts of N-methylol acrylamide, 0.2 parts of Mohr's salt and 200 parts of deionized water were added to the reactor and stirred evenly; 20 parts Acrylic acid, 0.9 parts of 2-mercaptoethanol, 0.44 parts of L-ascorbic acid and 30 parts of deionized water were evenly mixed to form a mixed solution. Control the initial temperature of the reaction at 12°C, add 0.25 parts of hydrogen peroxide to the reactor at one time, start adding the mixed solution dropwise, and finish the dropwise addition within 45 minutes; after the reaction, continue to keep warm at 35-45°C for 30 minutes, The material is transferred to the storage tank, and naturally cooled to room temperature; after the material is placed in the storage tank for 12 hours, 20 parts of sodium hydroxide solution with a mass concentration of 30% is ...

Embodiment 2

[0027] In parts by weight, 200 parts of CH 2 =CH(CH 3 )CH 2 CH 2 O(CH 2 CH 2 O) 110 (CH 2 CH 3 CHO) 10 H, 8 parts of acrylic acid, 1 part of dimethyl diallyl ammonium bromide, 3 parts of 2-methylpropanesulfonic acid acrylamide, 0.4 part of Mohr's salt and 200 parts of deionized water are added to the reactor and stirred evenly; 5 Part of acrylic acid, 0.9 part of 2-mercaptoacetic acid, 0.8 part of L-ascorbic acid and 30 parts of deionized water were evenly mixed to form a mixed solution. Control the initial temperature of the reaction at 30°C, add 0.8 parts of tert-butyl hydroperoxide to the reactor at one time, then start to add the mixed solution dropwise, and complete the dropwise addition within 30 minutes; after the reaction, continue to keep warm at 35-45°C After 30 minutes, the material was transferred to the storage tank, and naturally cooled to room temperature; after the material was placed in the storage tank for 18 hours, 12 parts of sodium hydroxide solut...

Embodiment 3

[0029] In parts by weight, 200 parts of CH 2 =CH(CH 3 )CH 2 CH 2 O(CH 2 CH 2 O) 90 (CH 2 CH 3 CHO) 2 H, 10 parts of acrylic acid, 5 parts of allyltrimethylammonium chloride, 3 parts of N,N-methylenebisacrylamide, 0.5 parts of Mohr's salt and 200 parts of deionized water were added to the reactor and stirred evenly; 12 Part of acrylic acid, 0.5 part of 3-mercaptopropanol, 0.2 part of L-ascorbic acid and 30 parts of deionized water were evenly mixed to form a mixed solution. Control the initial temperature of the reaction at 18°C, add 4 parts of cumene hydroperoxide to the reactor at one time, then start to add the mixed solution dropwise, and complete the dropwise addition within 30 minutes; after the reaction, continue to keep warm at 35-45°C After 30 minutes, the material was transferred to the storage tank, and naturally cooled to room temperature; after the material was placed in the storage tank for 20 hours, 18 parts of sodium hydroxide solution with a mass conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com