Degradable shape memory high polymer material of regular network structure and preparation method therefor

A polymer material and network structure technology, applied in the field of preparation of degradable shape memory polymer materials, can solve problems such as uneven distribution of crosslink density, weakened shape memory performance, and impaired mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] A four-armed macromonomer

[0022] Azido-functionalized four-arm poly D, L-lactide (M n =23000) 3g

[0023] Alkyne-terminated four-armed poly-D, L-lactide (M n =23000) 3g

[0024] B Catalyst

[0025] CuI 0.06g

[0026] C solvent

[0027] Dichloromethane 48g

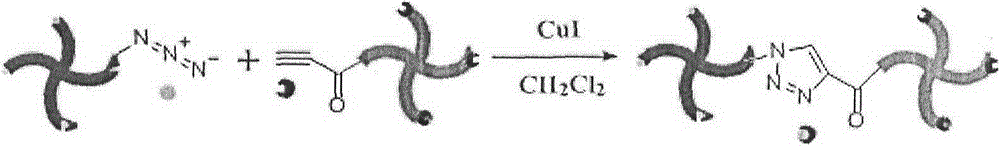

[0028] The reaction formula is as follows:

[0029]

[0030] The preparation method is as follows: azido and terminal alkyne functionalized four-arm macromolecular monomer, CuI and dichloromethane are added into a reaction bottle, stirred and dissolved at room temperature, and injected into a reaction mold. React at 60° C. for 6-12 hours, and dry after demoulding to obtain a shape-memory material with a regular network structure.

[0031] Product indicators:

[0032] Glass transition temperature: 46°C;

[0033] Shape recovery rate at 51°C: 99%;

[0034] Shape recovery time: 5 seconds.

example 2

[0036] A four-armed macromonomer

[0037] Thiol-functionalized four-arm polycaprolactone (M n =46000) 3g

[0038] Norbornene-functionalized four-arm polycaprolactone (M n =46000) 3g

[0039] B Catalyst

[0040] Photoinitiator (2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone) 0.06g

[0041] C solvent

[0042] Dichloromethane 48g

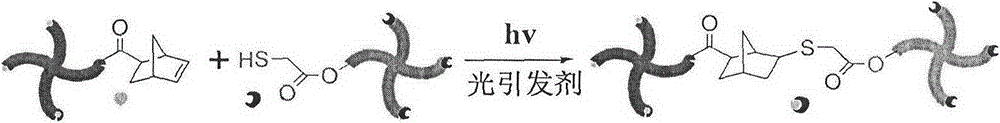

[0043] The reaction formula is as follows:

[0044]

[0045] The preparation method comprises: adding mercapto group and norbornene functionalized four-arm macromolecular monomer, photoinitiator and dichloromethane into a reaction bottle, stirring and dissolving at room temperature, and injecting into a reaction mold. Under the condition of room temperature, the ultraviolet light is reacted for 1-10 minutes, and the shape memory material with regular network structure can be obtained after demolding and drying.

[0046] Product indicators:

[0047] Melting point: 54°C;

[0048] Shape recovery rate at 70°C: 99%;

[0049] Shape recovery...

example 3

[0051] A four-armed macromonomer

[0052] Methylfuran functionalized four-arm polylactide-co-caprolactone (M n =10500) 3g

[0053] Maleic anhydride functionalized four-arm polylactide-co-caprolactone (M n =10500) 3g

[0054] B Catalyst

[0055] Photoinitiator (2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone) 0.06g

[0056] C solvent

[0057] Dichloromethane 48g

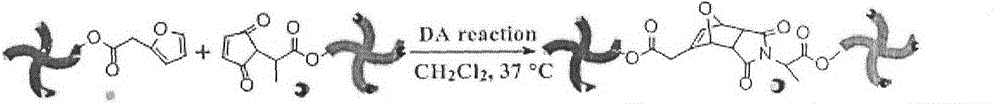

[0058] The reaction formula is as follows:

[0059]

[0060] The preparation method is as follows: methyl furan and maleic anhydride functionalized four-arm polylactide-co-caprolactone, a photoinitiator and methylene chloride are added into a reaction bottle, stirred and dissolved at room temperature, and injected into a reaction mold. React at 37°C for 6-12 hours, and dry after demoulding to obtain a shape-memory material with a regular network structure.

[0061] Product indicators:

[0062] Glass transition temperature: 36°C;

[0063] Shape recovery rate at 40°C: 99%;

[0064] Shape recovery time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com