Method for preparing nano-microporous polymer thin-film material

A polymer film and nano-micropore technology, which is applied in the field of surface materials, can solve the problems of high structural requirements, unstable structure and high cost, and achieve the effects of strong mechanical and physical properties, convenient operation and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1) Take a copolymer of sodium acrylate and acrylamide, prepare it into an aqueous solution, stir at room temperature for 1 hour, then add glutaraldehyde whose mass is 3% of the polymer mass, and continue stirring for 1 hour to obtain a coating solution.

[0050] 2) Clean the substrate used, such as a silicon wafer, after H 2 o 2 and H 2 SO 4 (v H2O2 / v H2SO4 =1:3) The mixture was treated at 80°C for 0.5h, rinsed with water, and dried in an oven at 70°C for use.

[0051] 3) The polymer solution was evenly coated on the glass substrate by the method of spin coating.

[0052] 4) Then the coating was cured at 40°C to form a film, and the heating time was 5 hours to obtain a smooth coating with a thickness of about 6 μm.

[0053] 5) Soak the above-mentioned coating in 0.2mol / l sodium chloride solution for 1 hour, after taking it out, wash it with clean water for 30 seconds and then wash it with N 2 Blow drying to obtain the anionic polymer microporous film coating.

...

Embodiment 2

[0057] 1) Take the copolymer of methacrylic acid and acrylamide, prepare it into an aqueous solution, stir at room temperature for 1 hour, then add glutaraldehyde whose mass is 15% of the polymer mass, and continue stirring for 1 hour to obtain a coating solution.

[0058] 2) Clean the substrate used, such as glass, after H 2 o 2 and H 2 SO 4 (v H2O2 / v H2SO4 =1:3) The mixture was treated at 80°C for 0.5h, rinsed with water, and dried in an oven at 70°C for use.

[0059] 3) The polymer solution is uniformly coated on the glass substrate by dip coating.

[0060] 4) Then the coating was cured at 80°C to form a film, and the heating time was 2 hours to obtain a smooth coating with a thickness of about 10 μm.

[0061] 5) Soak the above coating in 2mol / l Na 2 SO 4 After being in the solution for 1 hour, take it out, rinse it with water for 30 seconds, and then dry it in vacuum to obtain an anionic polymer microporous film coating.

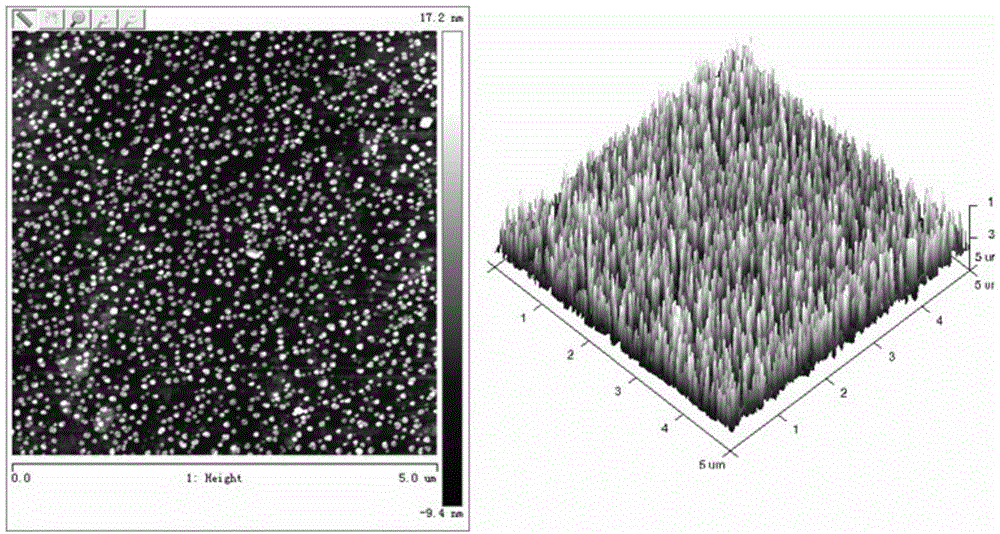

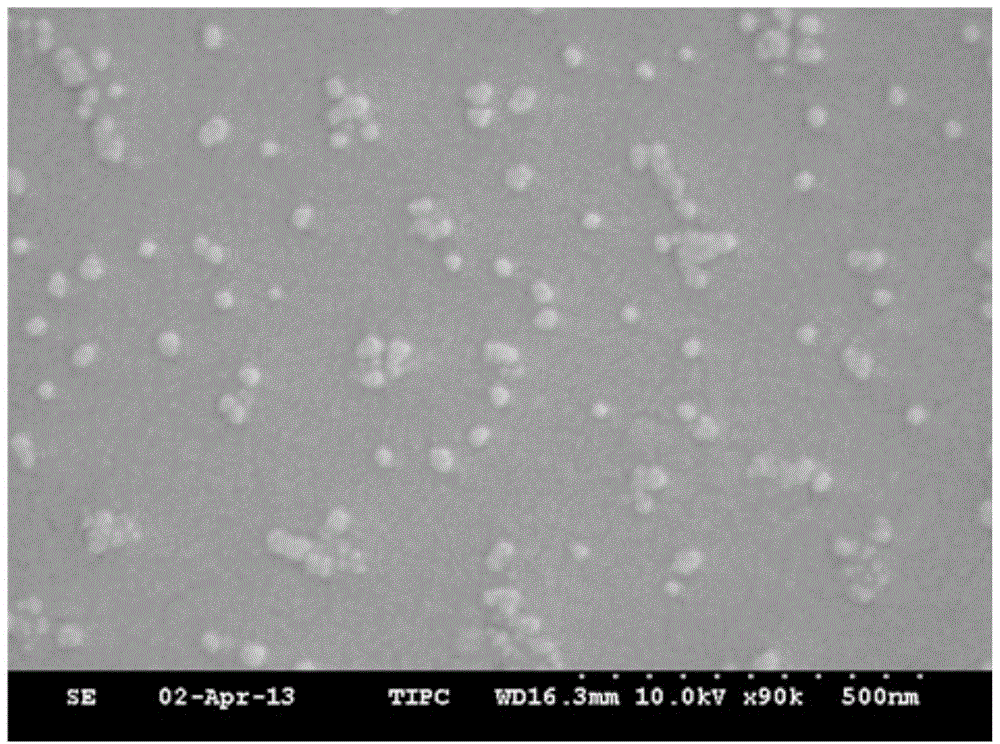

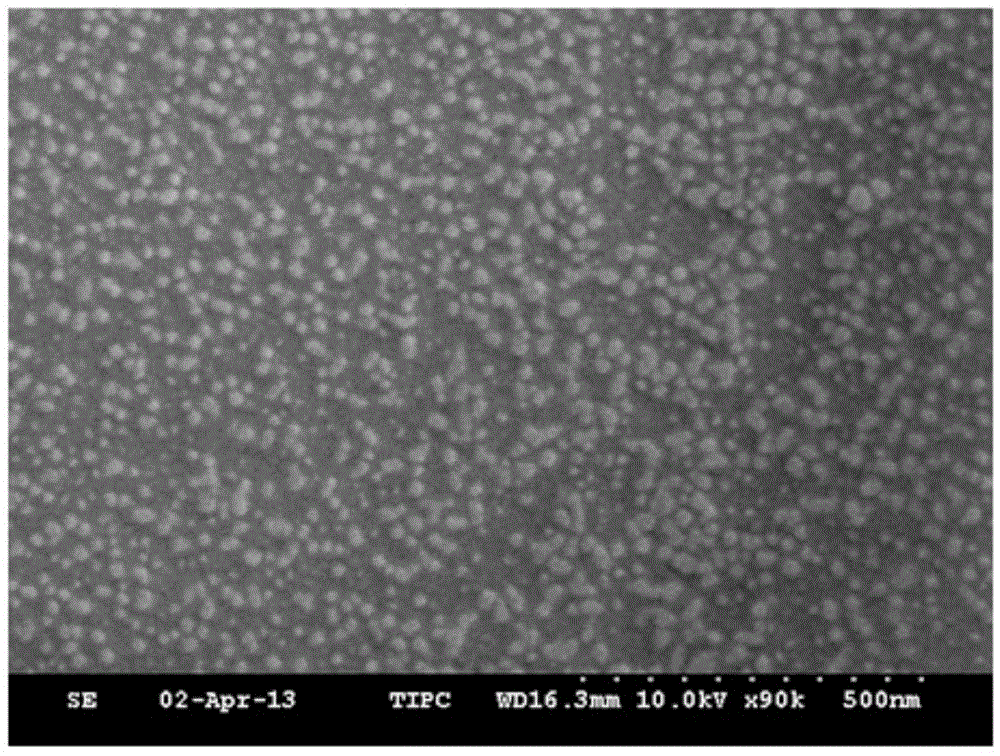

[0062] 6) AFM (Bruker Multimodoe8) was u...

Embodiment 3

[0064] 1) Prepare an anionic copolymer of acrylic acid and acrylamide into an aqueous solution, stir at room temperature for 1 h, then add glutaraldehyde whose mass is 10% of the polymer mass, and continue stirring for 1 h to obtain a coating solution.

[0065] 2) Clean the substrate used, such as glass, after H 2 o 2 and H 2 SO 4 (v H2O2 / v H2SO4 =1:3) The mixture was treated at 80°C for 0.5h, rinsed with water, and dried in an oven at 70°C for use.

[0066] 3) The polymer solution is evenly coated on the glass substrate by scraping method.

[0067] 4) Then the coating was cured at 60°C to form a film, and the heating time was 3 hours to obtain a smooth coating with a thickness of about 10 μm.

[0068] 5) Soak the above-mentioned coating in 0.2mol / l KCL solution for 1 hour, take it out, rinse it with clean water for 30 seconds, and then dry it with blower to obtain an anionic polymer microporous film coating.

[0069] 6) AFM was used to observe the surface microstructu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com