Aqueous rotating rust steel iron surface treatment liquid and preparation method thereof

A steel surface, self-rotating rust technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of less water-based anti-corrosion coatings, less surface treatment liquid for rusty steel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

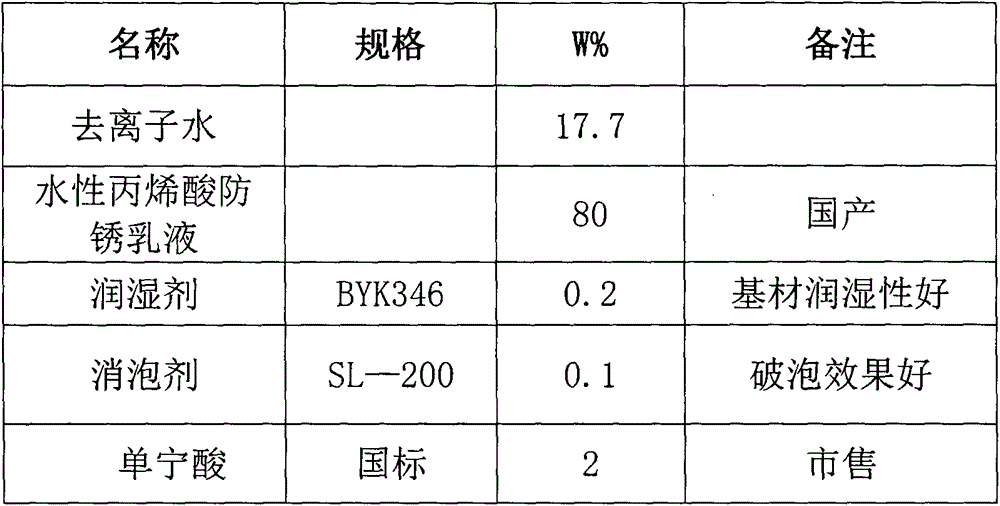

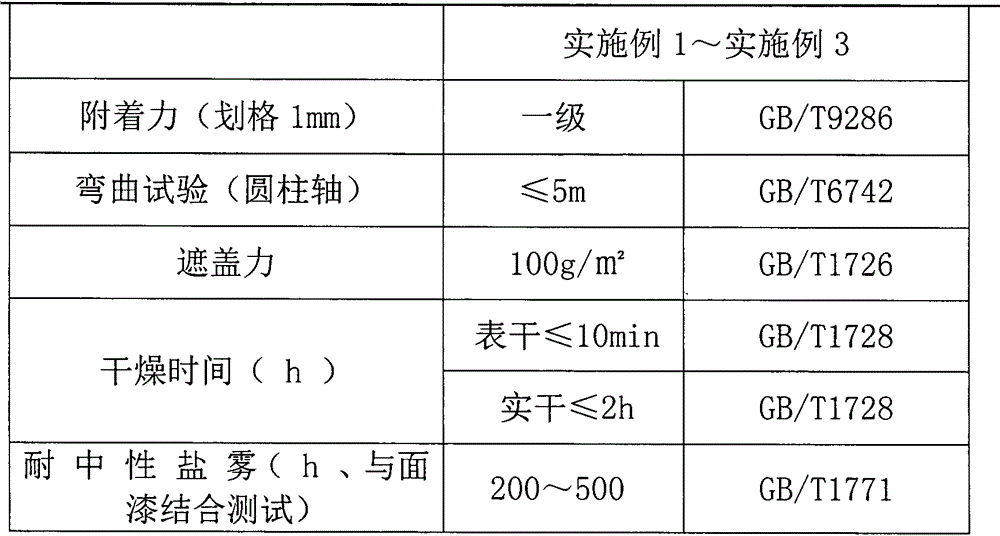

Embodiment 1

[0021] A water-based self-rotating rusty steel surface treatment solution, in terms of mass percentage, the composition of the water-based self-rotating rusty steel surface treatment solution is: 80% water-based acrylic acid antirust emulsion, 0.3% auxiliary agent, 2% tannic acid, and 17.7% deionized water.

[0022] Auxiliaries include wetting agent and defoaming agent. The mass ratio of wetting agent and defoaming agent to the whole water-based self-rotating rust steel surface treatment solution is 0.2% and 0.1%, respectively. The solid content of water-based acrylic antirust emulsion for 42%.

[0023] The preparation method of water-based self-rotation rust iron and steel surface treatment liquid as mentioned above may further comprise the steps:

[0024] 1): According to the proportion, first put deionized water into the mixing tank, heat it to 50°C, add tannic acid while stirring, control the rotation speed at 300 rpm, and stir until the tannic acid is completely dissolve...

Embodiment 2

[0030] A water-based self-rotating rusty steel surface treatment solution, in terms of mass percentage, the composition of the water-based self-rotating rusty steel surface treatment solution is: 75% water-based acrylic acid antirust emulsion, 0.4% auxiliary agent, 4.6% tannic acid, and 20% deionized water.

[0031] Auxiliaries include wetting agent and defoaming agent. The mass ratio of wetting agent and defoaming agent to the whole water-based self-rotating rust steel surface treatment solution is 0.2% and 0.2%, respectively. The solid content of water-based acrylic antirust emulsion 45%.

[0032] The preparation method of water-based self-rotation rust iron and steel surface treatment liquid as mentioned above may further comprise the steps:

[0033] 1): According to the proportion, first put deionized water into the mixing tank, heat it to 60°C, add tannic acid while stirring, control the rotation speed at 500 rpm, and stir until the tannic acid is completely dissolved to...

Embodiment 3

[0036] A water-based self-rotating rusty steel surface treatment solution, in terms of mass percentage, the composition of the water-based self-rotating rusty steel surface treatment solution is: 78% water-based acrylic acid antirust emulsion, 0.2% auxiliary agent, 2.5% tannic acid, and 19.3% deionized water.

[0037] Auxiliaries include wetting agent and defoaming agent. The mass ratio of wetting agent and defoaming agent to the entire water-based self-rotating rust steel surface treatment solution is 0.1% and 0.1%, respectively. The solid content of water-based acrylic antirust emulsion was 44%.

[0038] The preparation method of water-based self-rotation rust iron and steel surface treatment liquid as mentioned above may further comprise the steps:

[0039] 1): According to the proportion, first put deionized water into the mixing tank, heat it to 55°C, add tannic acid while stirring, control the rotation speed at 400 rpm, stir until the tannic acid is completely dissolved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com