Fluorescence coded microspheres based on long-life composite quantum dots and preparation method thereof

A fluorescent coding and composite quantum technology, which is applied in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of difficult coding and unstable fluorescence intensity, achieve good biocompatibility and improve biological safety. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

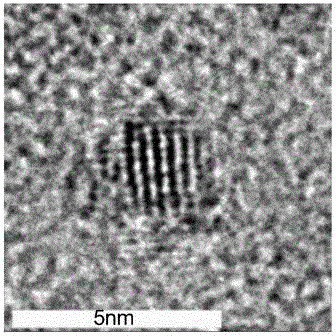

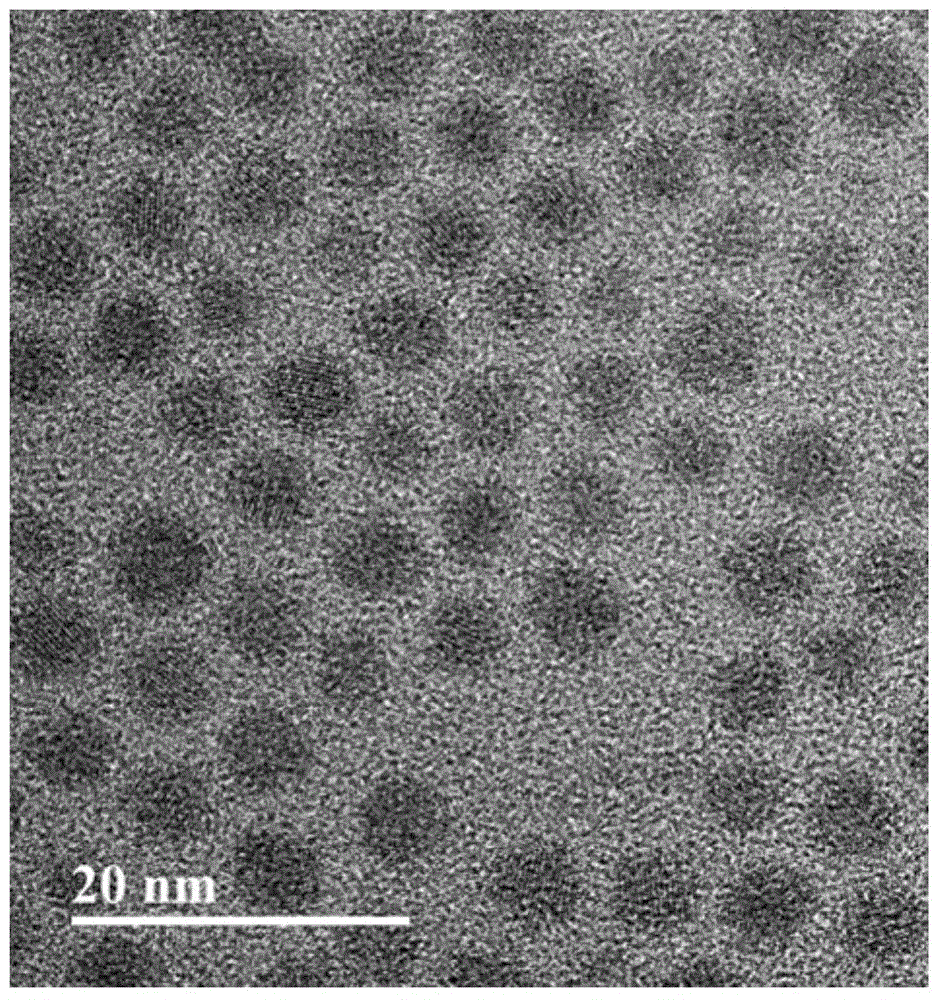

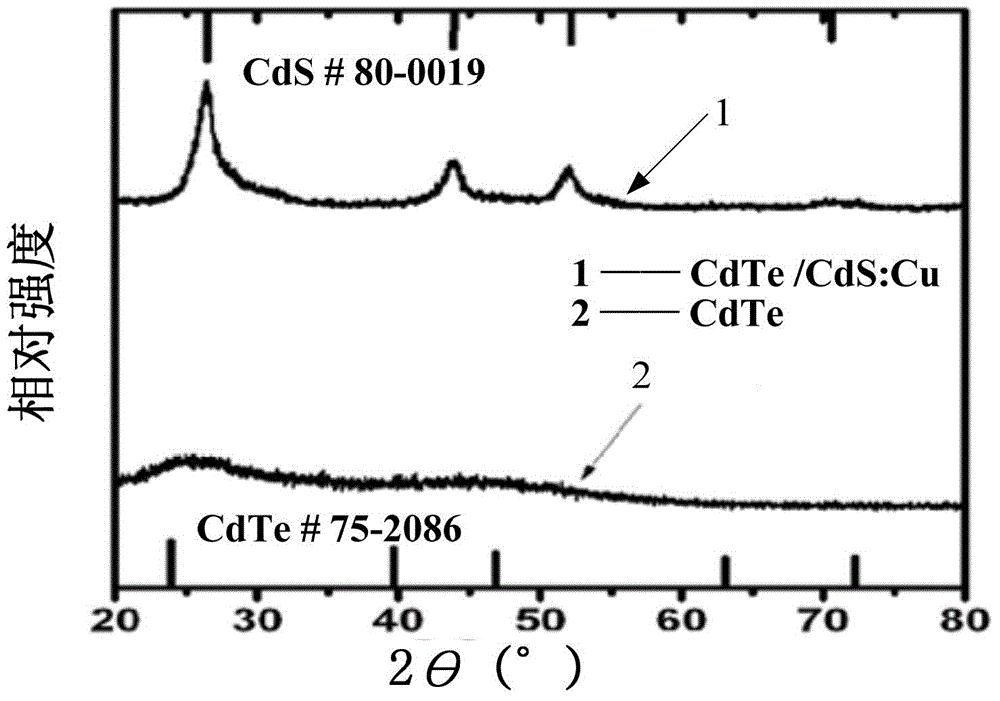

[0073] The preparation method of the first quantum dot specifically comprises the following steps:

[0074] (1) Preparation of Cd 2+ CdCl with a concentration of 0.1mol / L 2 Aqueous solution, a concentration of 0.2mol / L 3-mercaptopropionic acid aqueous solution, Cu 2+ CuCl with a concentration of 0.1mol / L 2 aqueous solution, spare;

[0075] (2) Newly prepared NaHTe solution: NaBH with a molar ratio of 4.5:1 4 Dissolve Te powder in ultrapure water and react at room temperature for 5 hours to obtain NaHTe solution;

[0076] (3) Preparation of CdTe nucleus: take 5mL CdCl 2 Solution, 4.5mL of 3-mercaptopropionic acid solution was fixed to 30mL, transferred to a 50mL three-necked flask, adjusted to pH 10.5 with NaOH solution, passed argon gas into the three-necked flask for deoxygenation for 1 h, added 100 μL of newly prepared NaHTe solution, and Store at 4°C for 17 hours. Add 60mL of ethanol, centrifuge at 10000r / min for 15min, repeat centrifugation and alcohol washing three...

Embodiment 2

[0084] The preparation method of the first quantum dot specifically comprises the following steps:

[0085] (1) Preparation of Cd 2+ CdCl with a concentration of 0.1mol / L 2 Aqueous solution, a concentration of 0.2mol / L 3-mercaptopropionic acid aqueous solution, Cu 2+ Water CuCl with a concentration of 0.1mol / L 2 solution, spare;

[0086] (2) Newly prepared NaHTe solution: NaBH with a molar ratio of 4.5:1 4 Dissolve Te powder in ultrapure water and react at room temperature for 5 hours to obtain NaHTe solution;

[0087] (3) Preparation of CdTe core: Take 5mL CdCl 2 Solution, 4.5mL of 3-mercaptopropionic acid solution was fixed to 30mL, transferred to a 50mL three-necked flask, adjusted to pH 10.5 with NaOH solution, passed argon gas into the three-necked flask for deoxygenation for 1 h, added 100 μL of newly prepared NaHTe solution, and Store at 4°C for 17 hours. Add 60mL of ethanol, centrifuge at 10000r / min for 15min, repeat centrifugation and alcohol washing three time...

Embodiment 3

[0094] The preparation method of the first quantum dot specifically comprises the following steps:

[0095] (1) Preparation of Cd 2+ CdCl with a concentration of 0.1mol / L 2 Aqueous solution, a concentration of 0.2mol / L 3-mercaptopropionic acid aqueous solution, Cu 2+ CuCl with a concentration of 0.1mol / L 2 aqueous solution, spare;

[0096] (2) Newly prepared NaHTe solution: NaBH with a molar ratio of 4.5:1 4 Dissolve Te powder in ultrapure water and react at room temperature for 5 hours to obtain NaHTe solution;

[0097] (3) Preparation of CdTe core: Take 5mL CdCl 2 Solution, 4.5mL of 3-mercaptopropionic acid solution was fixed to 30mL, transferred to a 50mL three-necked flask, adjusted to pH 10.5 with NaOH solution, passed argon gas into the three-necked flask for deoxygenation for 1 h, added 100 μL of newly prepared NaHTe solution, and Store at 4°C for 17 hours. Add 60mL of ethanol, centrifuge at 10000r / min for 15min, repeat centrifugation and alcohol washing three ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com